Microwave nondestructive testing method for internal defects of eddy-current-assisted welded metal plate

A technology for internal defects and auxiliary welding, which is applied in the directions of using microwave flaw detection, measuring devices, measuring electrical variables, etc., to achieve the effects of simple structure, extended use range and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The present invention is an eddy current-assisted microwave non-destructive detection method for internal defects of welded metal plates, the steps are as follows:

[0024] Step 1: According to the test requirements, select the low-frequency excitation coil, and select the appropriate excitation frequency, so that the excitation frequency can generate a constant eddy current in the area of the welded metal plate with a depth greater than 2mm;

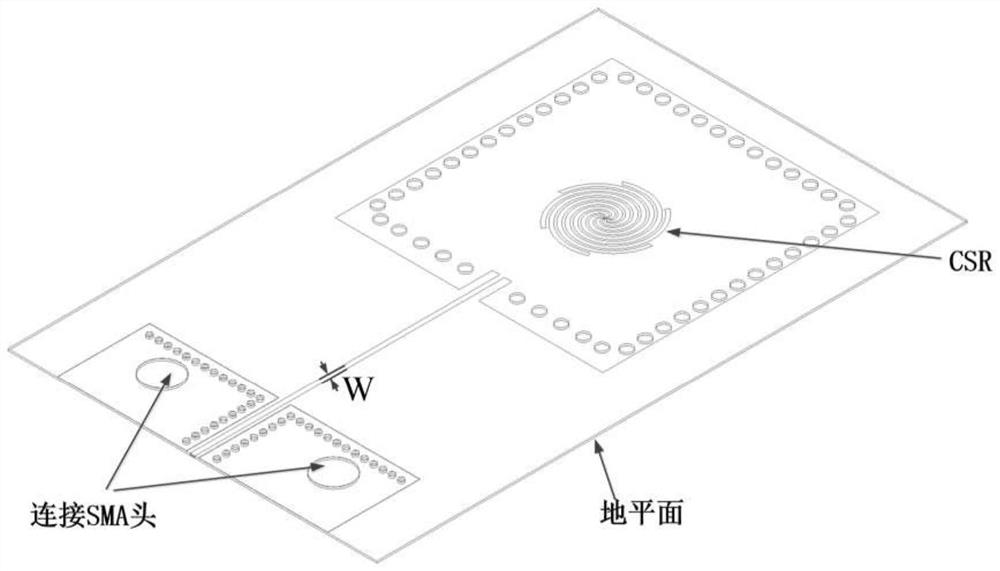

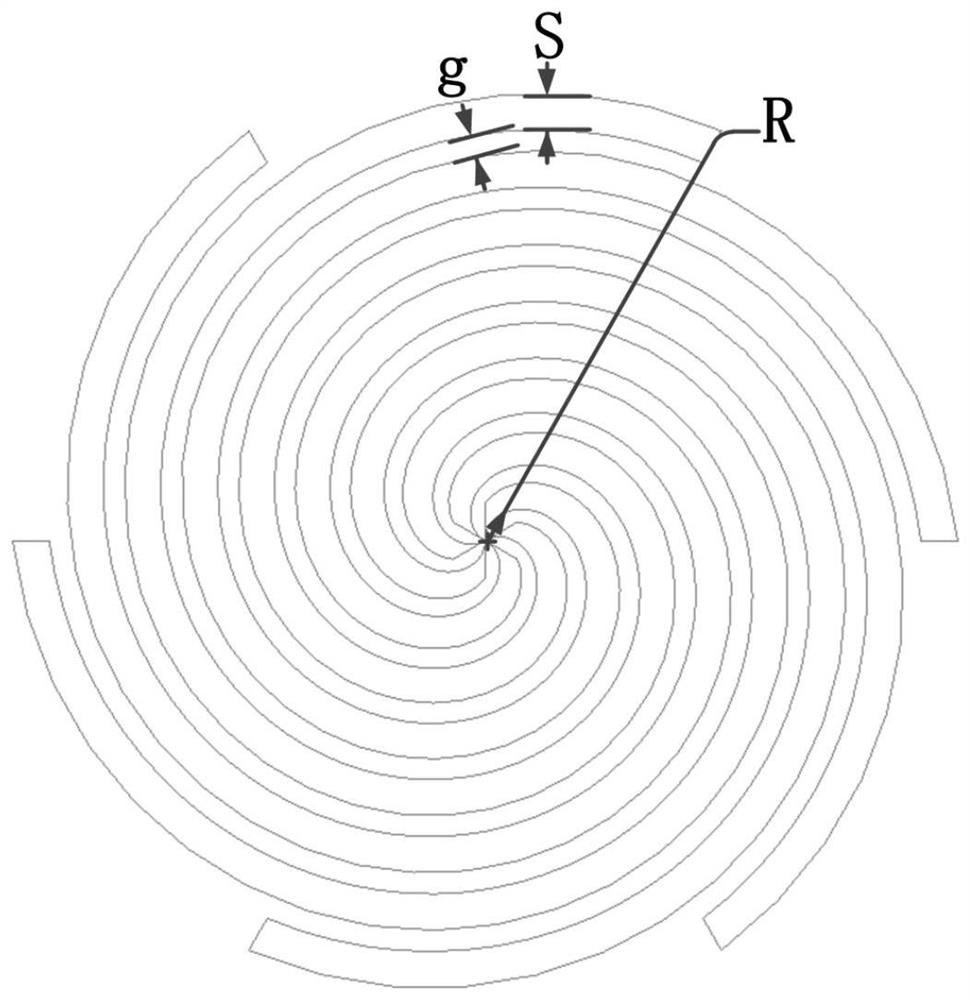

[0025] Step 2: Design the CSR detection unit, as follows:

[0026] According to the detection accuracy requirements of the internal defects of the welded metal plate, the double-sided copper-clad microwave PCB board is selected, and the CSR detection unit is designed in the three-dimensional electromagnetic simulation software HFSS according to the dielectric parameters of the selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com