Preparation method of epoxy board with glass fabric sandwiched

A technology of sandwiching glass fiber cloth and epoxy board, which is applied in the direction of electrical components, insulators, circuits, etc., can solve the problems of poor bonding force and low surface activity of epoxy board, so as to improve the flexural modulus of elasticity and enhance the core competitiveness of enterprises Good strength and product toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

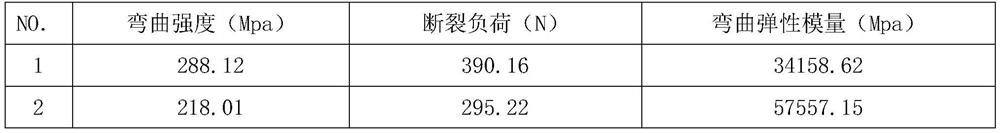

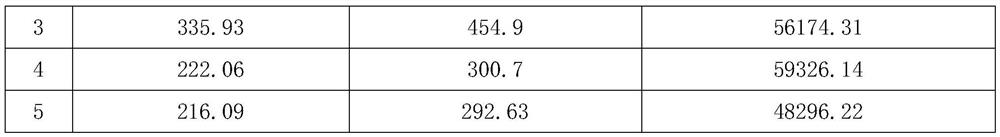

Examples

Embodiment 1

[0024] The preparation method of glass fiber cloth epoxy board comprises the following steps:

[0025] S1 Monohydroxyorganosiloxane M and trihydroxyorganosiloxane are hydrolyzed in a water bath (temperature 40±10°C) under the action of n-butanol as a catalyst; heat up to 110±20°C and reflux for 1 to 3 hours, then heat up to Evaporate by-products at 140 ± 20°C; add toluene to neutralize to neutral, add solvent toluene, adjust the solid content to 50 ± 10%, and make silicone water.

[0026] S2 uses the sizing process to make the organic silicon solvent penetrate into the mica paper and glass fiber cloth evenly; among them, the mica paper is made by the swirl papermaking process to ensure that the uniformity of the mica paper is ±2g / m 2 Within, make the mica paper that is suitable for the product use.

[0027] S12 Bake the volatiles in the volatile solvent through the drying tunnel to ensure that the mica paper and glass fiber cloth are dry and the solvent penetrates evenly afte...

Embodiment 2

[0035] Example 2 Compared with Example 1, adjust S12 to bake the volatile matter in the volatile solvent through the drying tunnel to ensure that the mica paper and glass fiber cloth are dry and the solvent penetrates evenly after gluing; the temperature in the front section of the drying tunnel is 20°C-60°C, The baking time is 0.5-2min, to preliminarily volatilize the volatiles in the solvent; the temperature in the middle section of the drying tunnel is 60°C-120°C, and the baking time is 0.5-2min, to further volatilize the volatiles in the solvent, and the temperature at the end of the drying tunnel The temperature is 100°C-140°C, the baking time is 0.5-2min, and the remaining volatilization in the solvent is volatilized.

Embodiment 3

[0036] Example 3 Compared with Example 1, adjust the S23 pressing process, after a long time of high temperature and high pressure, the solvent in the semi-finished blank is completely volatilized, and the remaining raw glue is completely cured with mica paper and glass fiber cloth to ensure that the finished product is good. strength. The pressing process is as follows: the first stage of pressing, the initial temperature is 100±15°C, the ending temperature is 100°C, the pressure is 1.5-12Mpa, the holding time is 10min, and the number of exhaust is 1 time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com