Control method and device of electromagnetic induction heating equipment and electromagnetic induction heating system

An electromagnetic induction heating and control method technology, which is applied in the control of electromagnetic induction heating equipment and the field of electromagnetic induction heating systems, can solve the problems of high cost of current sensor devices, large PCB area occupation, and zero-crossing detection deviation, so as to improve EMC reliability. performance, reduce control costs, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

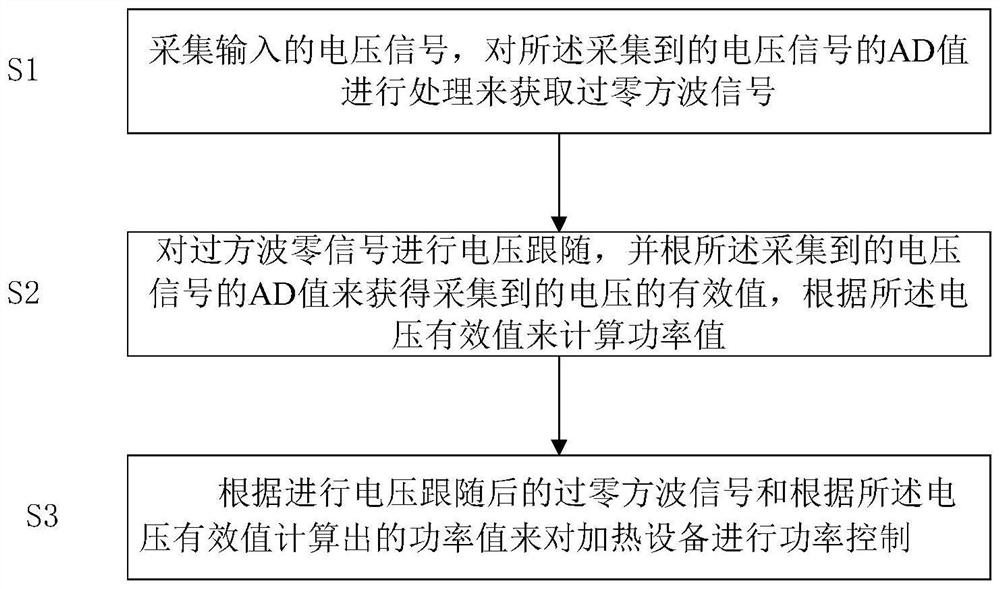

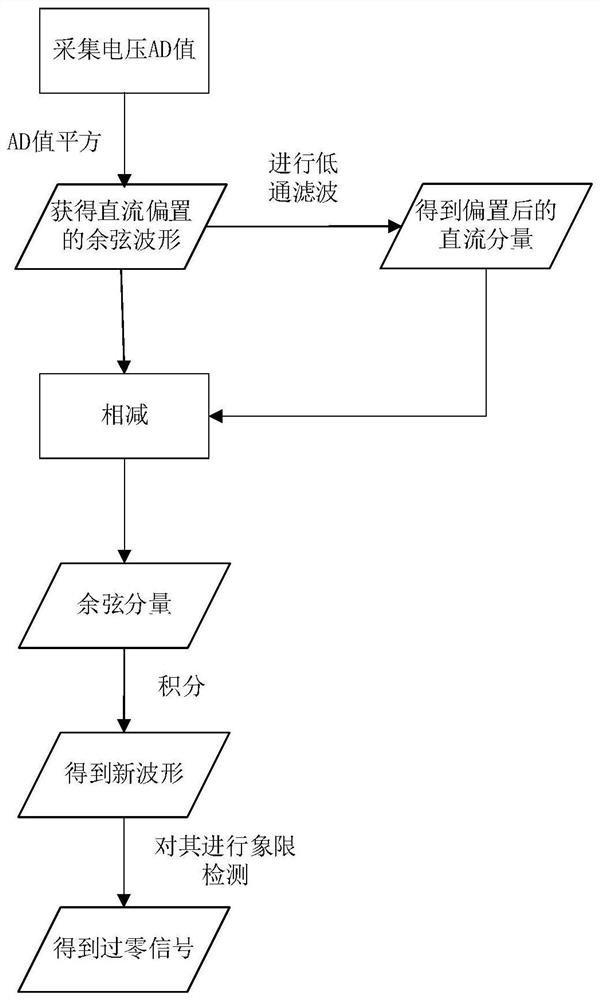

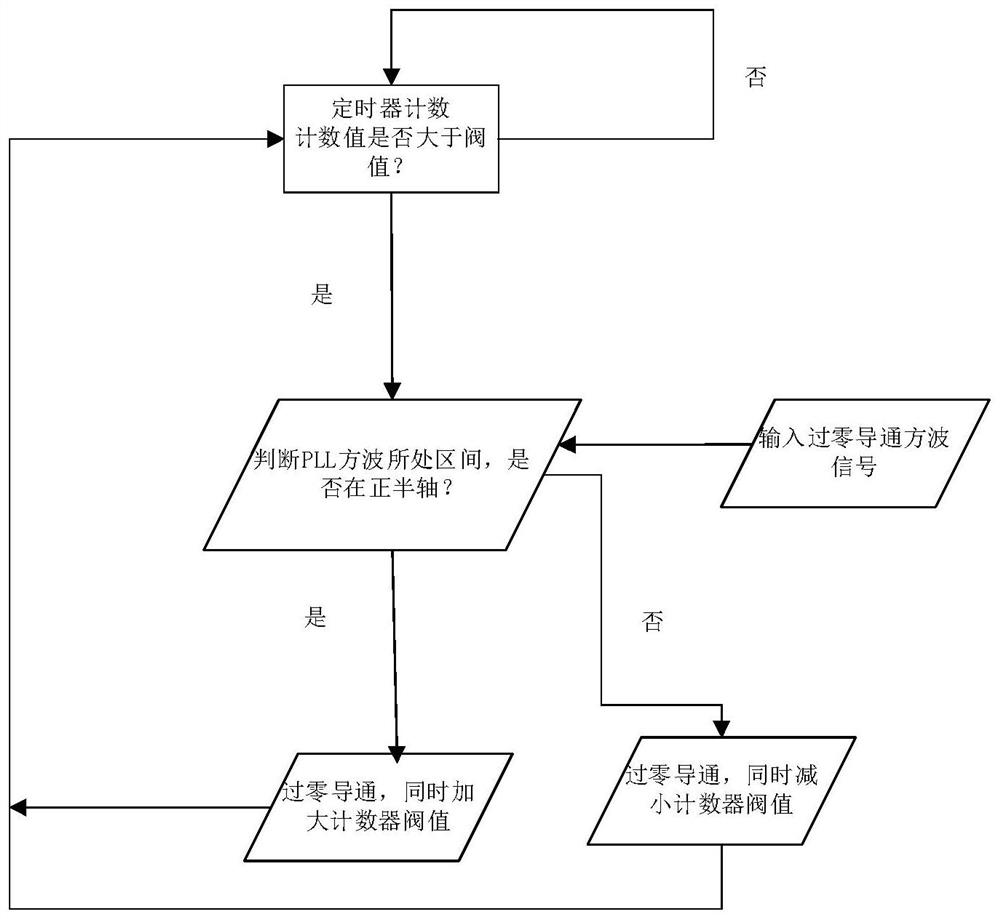

Method used

Image

Examples

Embodiment Construction

[0027] As used herein, the word "first", "second", or the like can be used to describe the elements in the exemplary embodiments of the present invention. These words are only used to distinguish a component and another component, and the inherent characteristics or order of the corresponding elements is not limited by the word. All terms (including techniques or scientific terms) used herein have the same integrated integration of ordinary skill in the art of the present invention, unless otherwise defined. Those terms as defined in the Common Dictionary are explained in the same meaning as the context meaning in the art in the art, and is not interpreted as having an ideal or too formal meaning, unless it is clearly defined in the present invention meaning.

[0028] Those skilled in the art will appreciate that the apparatus and method described herein and the apparatus and methods of the invention are unlimited, and the scope of the invention is limited only by the claims. Feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com