Manufacturing method of hysteroscope head end channel

A manufacturing method and channel technology, applied in the field of hysteroscopy, can solve problems such as unreasonable use of structural space, bloated structure, and increased number of structural parts, and achieve significant promotion and application significance, better convection effect, and increased diameter upper limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention first prepares a double-channel tube, and on the basis of the formation of the double-channel tube, it also has different preparation methods for the end channels of the hysteroscopic lens, which all include the following basic steps:

[0057] S1. Prepare a hollow tube with a closed circular cross section as the base tube 1, and the inner space of the base tube 1 is used as the first channel;

[0058] In step S1, the closed ring includes but not limited to common closed shapes such as circle and square, and the base tube 1 can be prepared by one-time premolding.

[0059] S2. Prepare a segment with an arc cross section as the adapter tube 2, the segment has two opposite arc sides and two opposite straight sides;

[0060] In step S2, the segment with an arc cross section can be one of two parts cut from a complete circular tube along a certain chord line, or a rectangular or square segment can be prepared first, It is then bent into a curved tube pi...

Embodiment 1

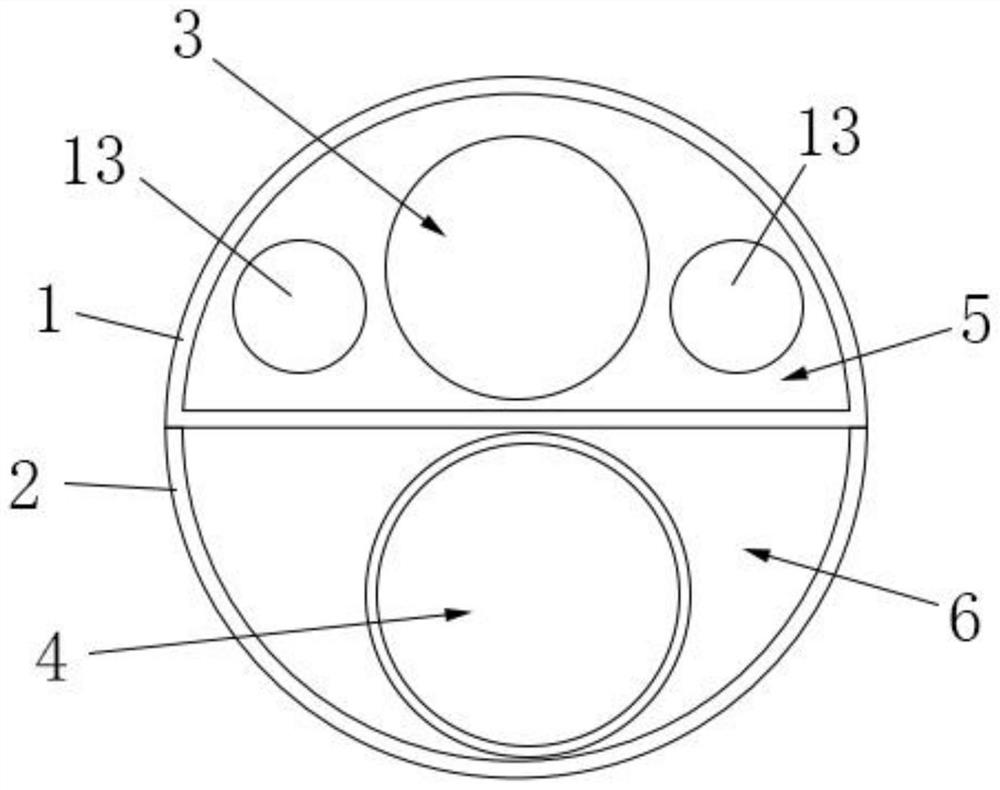

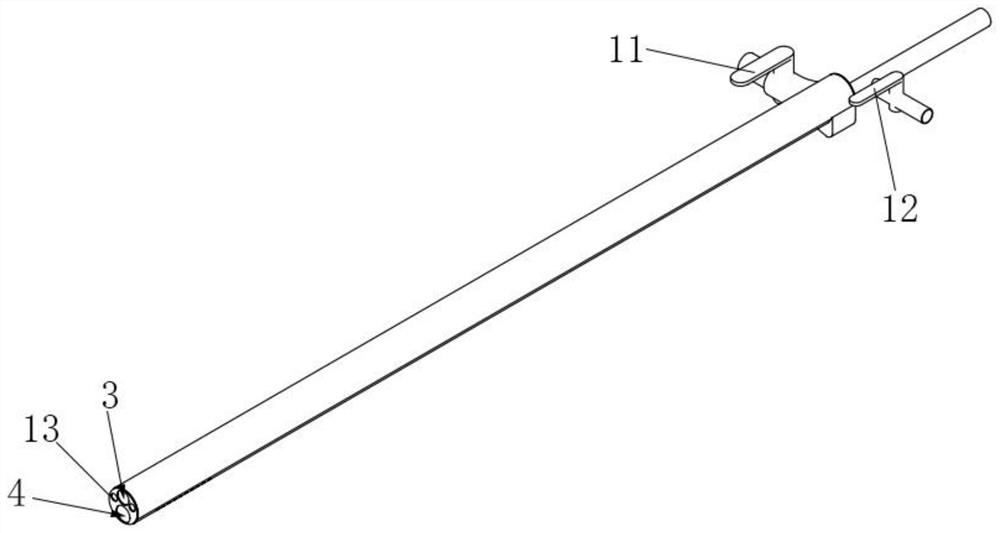

[0064] see Figure 1 to Figure 4 , in this embodiment, a method for manufacturing a hysteroscopic lens end channel with a specific structure is provided, and further improvements are made on the basic steps provided by the present invention, mainly including:

[0065] In step S1, the prepared base pipe 1 is composed of a semicircular arc surface and a plane, the cross-sectional shape of the pipe is "D", and the connection between the semicircle arc surface and the plane is two straight lines;

[0066] In step S2, the cross-sectional shape of the prepared adapter tube 2 is semicircular;

[0067] In step S3, the two straight sides of the base tube 1 and the adapter tube 2 are correspondingly fixed to form a semicircular first channel and a semicircular second channel.

[0068] As a modified embodiment of this embodiment, the manufacturing method of the hysteroscopic lens end channel provided in this embodiment is:

[0069] In step S1, the prepared base pipe 1 is composed of tw...

Embodiment

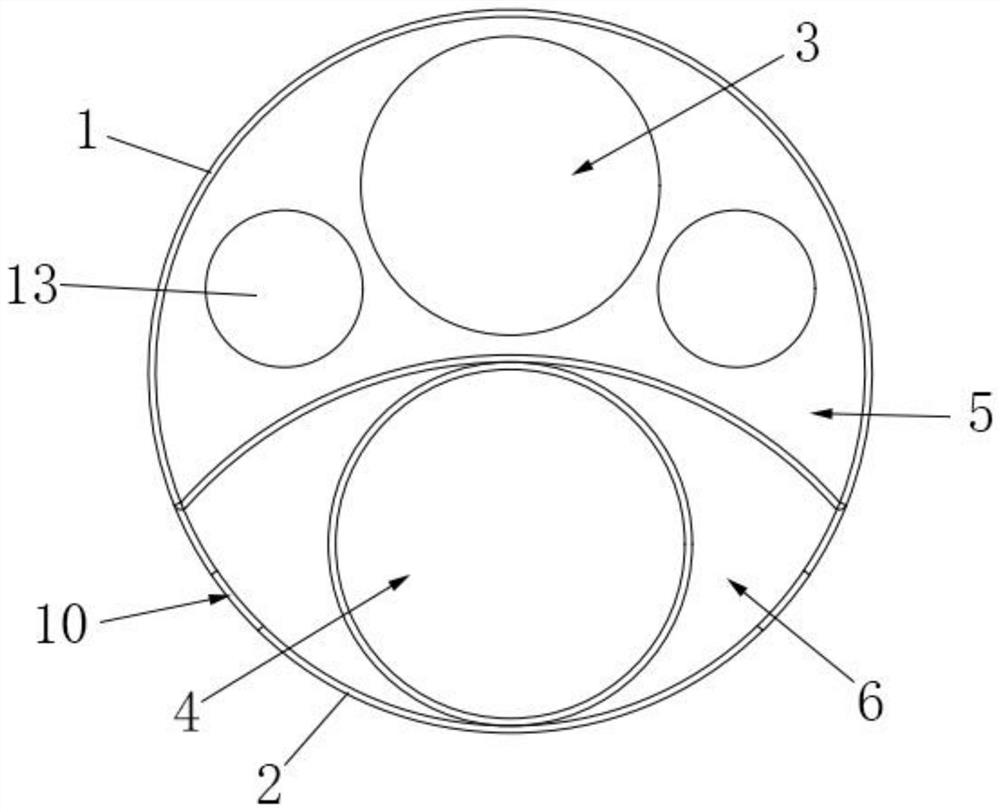

[0085] see Figure 8 to Figure 10 , in this embodiment, another method for manufacturing the end channel of the hysteroscopic lens with a specific structure is provided, which is further improved on the basic steps provided by the present invention, mainly including:

[0086] In step S1, the cross-section of the prepared base tube 1 is circular or oval;

[0087] In step S2, the prepared adapter tube 2 is sleeved on the base tube 1;

[0088] In step S3, the two straight edges of the prepared adapter tube 2 are fixed on the base tube 1 along the axis of the base tube 1, and the second channel formed is crescent-shaped.

[0089] After the above-mentioned embodiment is specifically implemented, the corresponding manufacturing method of the end channel of the hysteroscopic lens is as follows:

[0090] S4, using the first channel as a lens channel 3, and a lens module is arranged in the lens channel 3;

[0091] S5. Arrange an instrument channel 4 in the second channel, and arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com