Multidirectional forging forming method for titanium alloy complex die forging

A multi-directional forging and die forging technology, applied in the field of forging, can solve the problems of force size, difficult control of angle, influence of titanium alloy forging structure and properties, and difference in forging size, etc., to achieve balanced force and refinement of grains. , the effect of improving organizational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

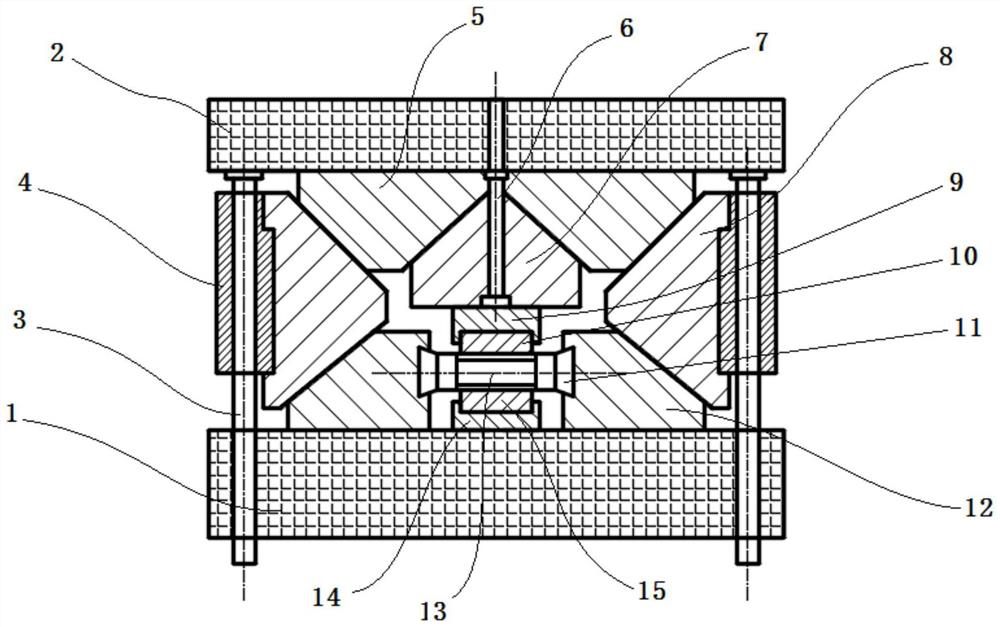

[0014] Make a multi-directional forging device: the device includes: lower cutting board 1, upper cutting board 2, guide connecting rod 3, slider 4, upper wedge 5, central connecting rod 6, tower block 7, middle wedge 8, upper die fixing Backing plate 9, upper mold 10, lateral mold 11, lower wedge 12, lower mold fixed backing plate 14, lower mold 15; the inclination angle of the contact surface between the upper wedge 5 and the tower block 7 is α, and the initial contact The area of the surface is S 1 ; The inclination angle of the contact surface between the upper wedge 5 and the middle wedge 8 is β, and the area of the initial contact surface is S 2 ; The inclination angle of the contact surface between the middle wedge 8 and the lower wedge 12 is θ;

[0015] The inclination angle α of the contact surface between the upper wedge 5 and the tower block 7, the area S of the initial contact surface 1 , the inclination angle β of the contact surface between the upper wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com