BOPP (Biaxially-oriented Polypropylene) film with low carbon dioxide emission and preparation method thereof

A technology of low carbon dioxide and carbon dioxide, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve ecological damage, environmental pollution and other problems, achieve carbon emission reduction, low cost, and easy rapid promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

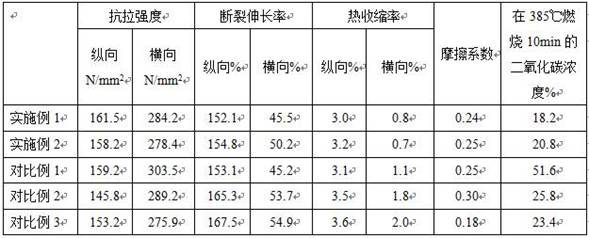

Examples

Embodiment 1

[0038] A kind of BOPP film of low carbon dioxide emission, comprises upper surface layer, core layer, lower surface layer arranged in sequence, and described upper surface layer comprises the following components by weight:

[0039] Homopolypropylene 95 parts

[0040] Anti-blocking agent 2 parts

[0041] Carbon dioxide reducer masterbatch 3 parts

[0042] The lower surface layer includes the following components by weight:

[0043] Homopolypropylene 95 parts

[0044] Anti-blocking agent 2 parts

[0045] Carbon dioxide reducer masterbatch 3 parts

[0046] The core layer includes the following components by weight:

[0047] Homopolypropylene 95.5 parts

[0048] Antistatic agent 1 part

[0049] Slippery agent 1.5 parts

[0050] Carbon dioxide reducer masterbatch 3 parts

[0051] Wherein, the carrier of the carbon dioxide reducing agent masterbatch is PP homopolymer, and the active ingredient is a carbon dioxide reducing agent with a concentration of 5w%. The carbon dioxi...

Embodiment 2

[0064] A kind of BOPP film of low carbon dioxide emission, comprises upper surface layer, core layer, lower surface layer arranged in sequence, and described upper surface layer comprises the following components by weight:

[0065] Homopolypropylene 95 parts

[0066] 3 parts anti-blocking agent

[0067] Carbon dioxide reducer masterbatch 2 parts

[0068] The lower surface layer includes the following components by weight:

[0069] Homopolypropylene 95 parts

[0070] 3 parts anti-blocking agent

[0071] Carbon dioxide reducer masterbatch 2 parts

[0072] The core layer includes the following components by weight:

[0073] Homopolypropylene 95.5 parts

[0074] Antistatic agent 2 parts

[0075] Slippery agent 1.5 parts

[0076] Carbon dioxide reducer masterbatch 2 parts

[0077] Wherein, the carrier of the carbon dioxide reducing agent masterbatch is PP homopolymer, and the active ingredient is a carbon dioxide reducing agent with a concentration of 5w%. The carbon diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com