Performance test method for replacing siliceous material with recycled glass fiber reinforced plastic powder

A technology of siliceous materials and testing methods, applied in the field of concrete, can solve the problems of no analysis and discussion of internal composition materials, no further research on concrete, etc., and achieve the effect of increasing the static stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

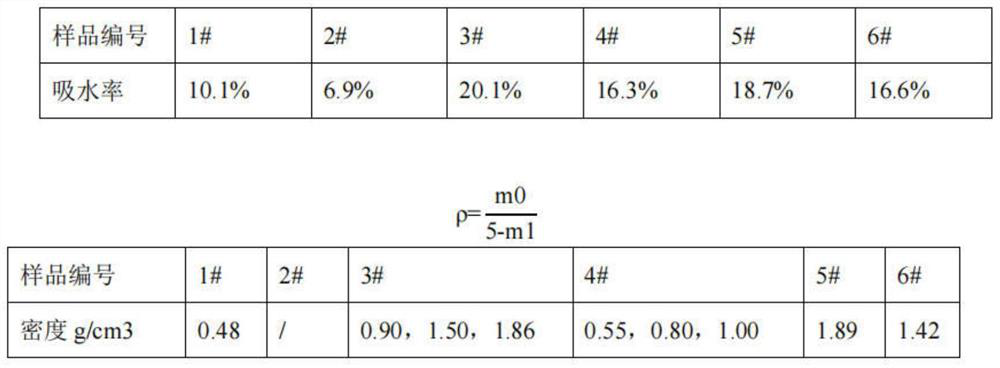

Examples

Embodiment 1

[0038] The concrete formulation process specifically includes the following steps:

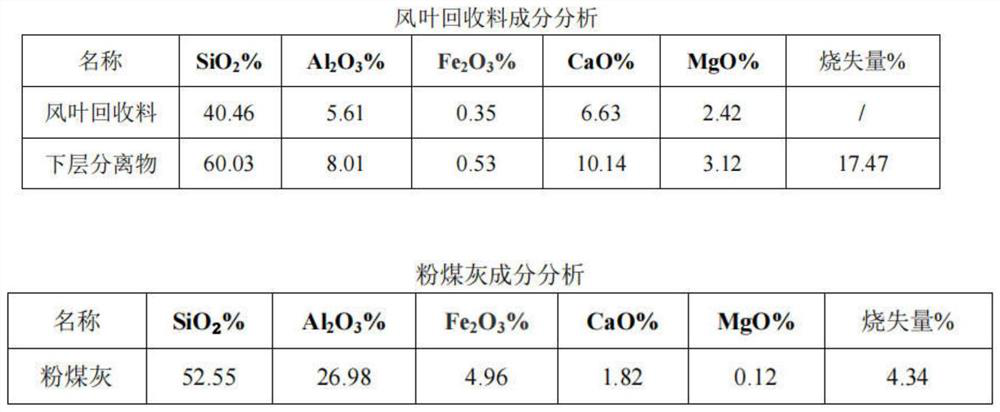

[0039] S1: Weigh fly ash, cement, lime, gypsum, aluminum powder paste, waste, wind blade recycled materials according to the experimental design plan, use an electronic balance accurate to 0.01 to weigh the materials, and make preparations before preparation ;

[0040] S2: Prepare and weigh the water temperature designed in the test plan, and accurately adjust the preparation conditions;

[0041] S3: Pour the weighed water into the mixing bucket, then add the fly ash, waste materials, and recycled fan blades into the water at the same time, and turn on the mixer to stir, so that all materials can be evenly stirred in the mixing bucket. For better dispersion, start stirring the material;

[0042] S4: Add gypsum and stir evenly, then add cement and lime, and stir until uniform. During this period, adjust the water consumption, determine the optimal water consumption through the degree of diffu...

Embodiment 2

[0061] The concrete formulation process specifically includes the following steps:

[0062] S1: Weigh fly ash, cement, lime, gypsum, aluminum powder paste, waste, wind blade recycled materials according to the experimental design plan, use an electronic balance accurate to 0.01 to weigh the materials, and make preparations before preparation ;

[0063] S2: Prepare and weigh the water temperature designed in the test plan, and accurately adjust the preparation conditions;

[0064] S3: Pour the weighed water into the mixing bucket, then add the fly ash, waste materials, and recycled fan blades into the water at the same time, and turn on the mixer to stir, so that all materials can be evenly stirred in the mixing bucket. For better dispersion, start stirring the material;

[0065] S4: Add gypsum and stir evenly, then add cement and lime, and stir until uniform. During this period, adjust the water consumption, determine the optimal water consumption through the degree of diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com