Thermal field adjusting device and method for single crystal growth

An adjustment device and field adjustment technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., to achieve the effects of fast cooling, increasing pulling speed, and reducing oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

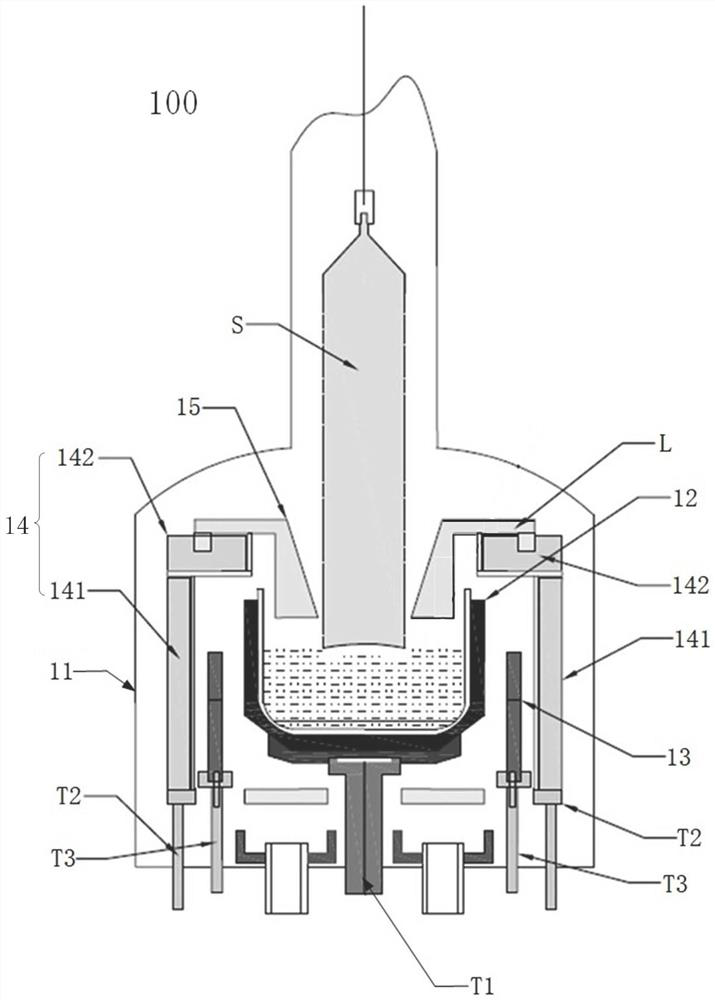

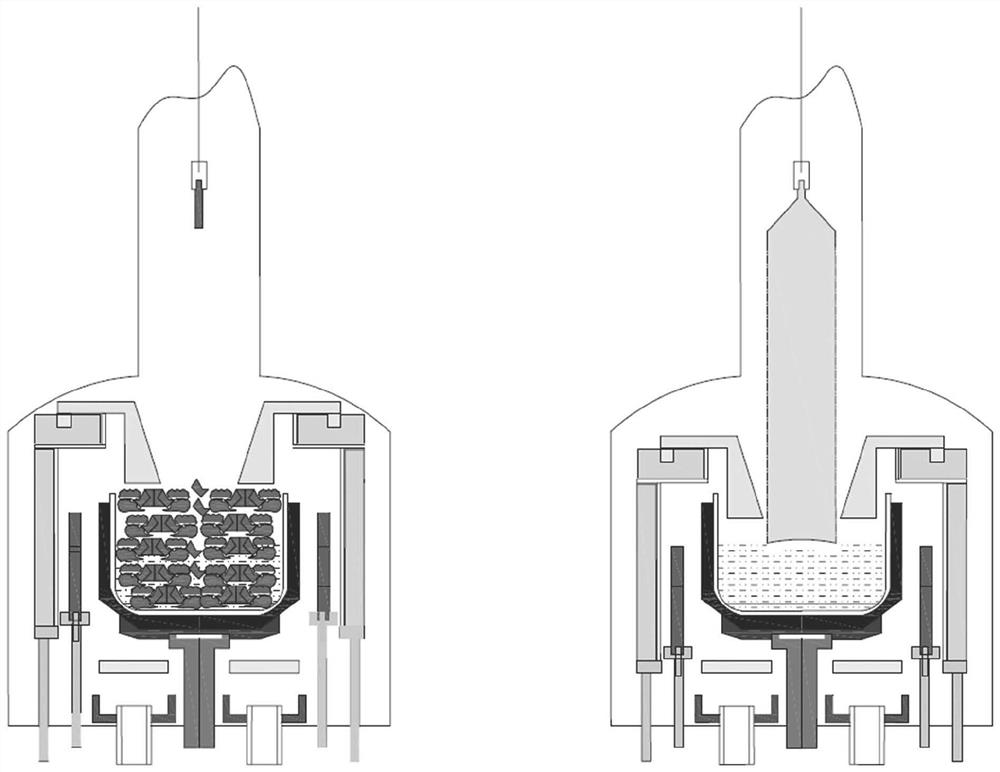

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0017] In the process of pulling single crystal silicon by CZ method in the crystal pulling furnace, the instability of the protective gas flow and the vibration caused by mechanical transmission will cause the problems of molten silicon liquid level vibration and single crystal silicon rod shaking during the rising process of the crucible. . Shaking single crystal silicon rods and unstable solid-liquid interface of molten silicon will destroy the stability of the thermal field in the crystal pulling furnace, leading to the formation of crystal defects. The above problems not only make it difficult for the crystal to grow without dislocation, but also have a very adverse effect on the quality of the crystal.

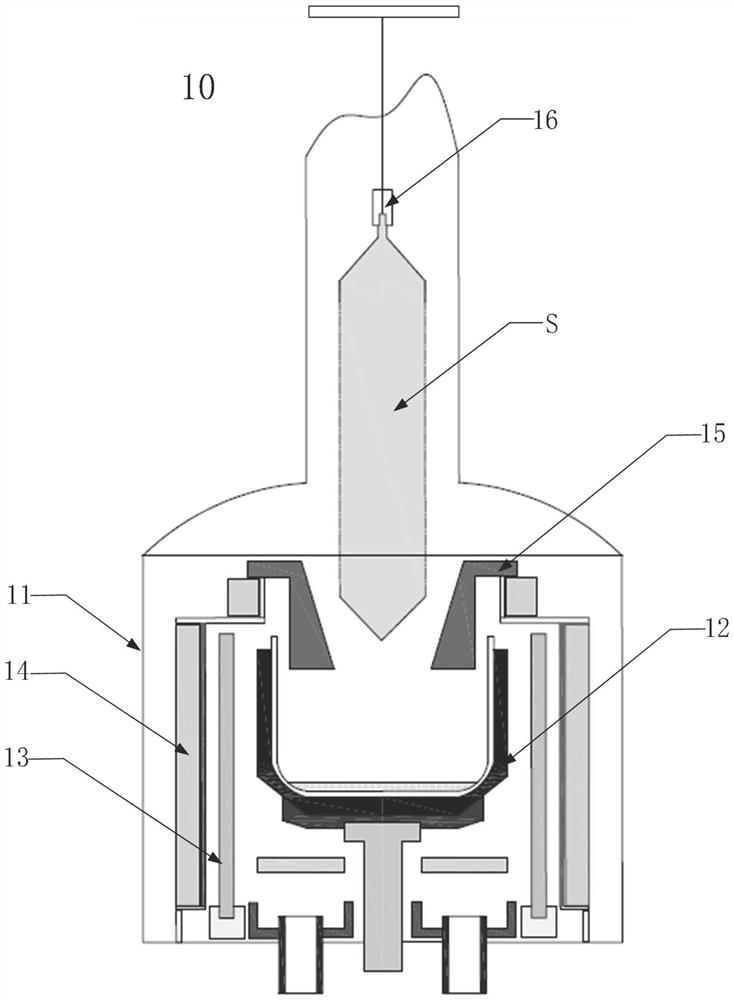

[0018] Continue to see attached figure 1 , as the crystal pulling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com