High-sensitivity acceleration measurement method and sensor based on optical fiber optical tweezers

An acceleration sensor and acceleration measurement technology, applied in speed/acceleration/shock measurement, acceleration measurement using inertial force, acceleration measurement, etc., can solve complex optical path structure, difficult to realize sensor miniaturization and low cost, and difficult to measure accurately Acceleration and other problems can be solved to achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

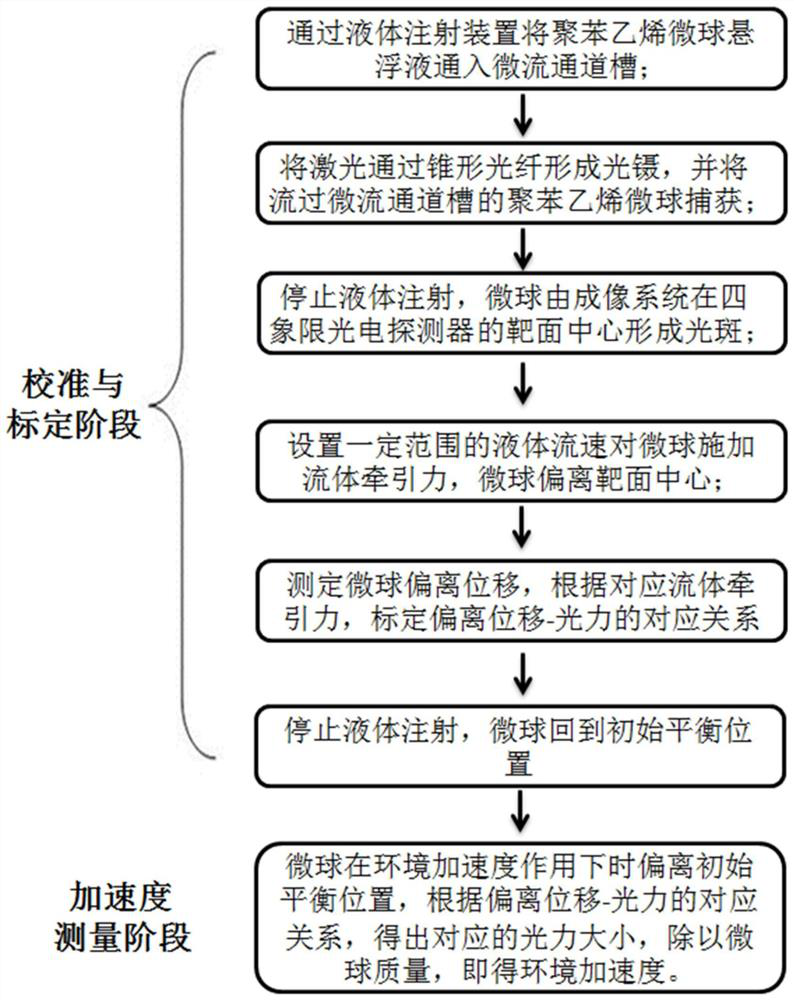

[0044] Such as figure 1 As shown, the present embodiment provides a highly sensitive acceleration measurement method based on fiber optic tweezers, comprising the following steps:

[0045] S1. Start the LED light source and CCD imaging system to observe the environment in the microfluidic channel tank in real time;

[0046] S2. Pass the polystyrene microsphere suspension into the microfluidic channel groove through a liquid injection device (a syringe pump is used in this embodiment);

[0047] In this embodiment, the initial flow rate is set at 100 μm / s, and the diameter of the polystyrene microspheres is 50 μm.

[0048]S3, forming optical tweezers by passing the laser light through the tapered optical fiber, and capturing the polystyrene microspheres flowing through the microfluidic channel groove;

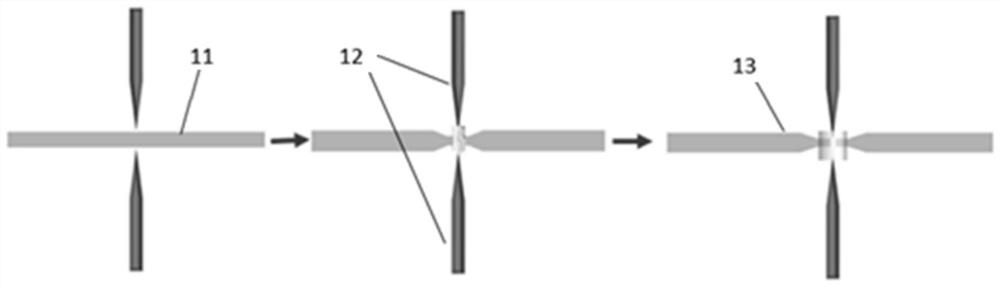

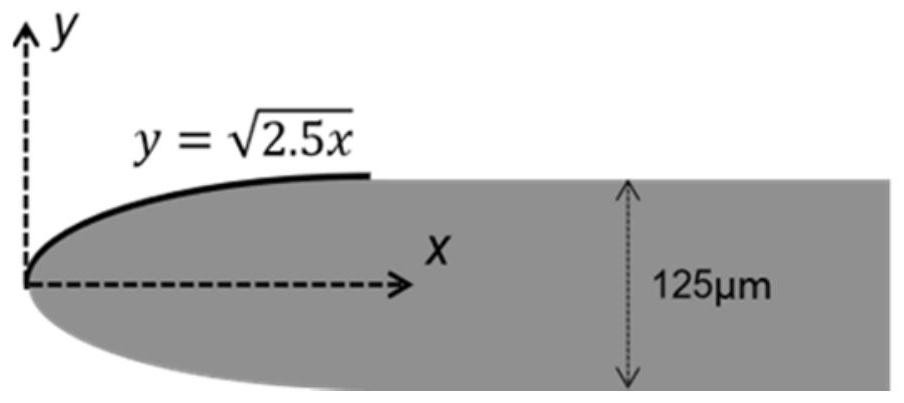

[0049] In this embodiment, a laser with an output laser wavelength of 980nm and a fixed power of 20mW is used to connect the tapered optical fiber. The tapered optical fiber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com