Solution for electrochemically repairing concrete cracks and preparation method thereof

A concrete and electrochemical technology, which is applied in the field of electrochemical repair of concrete cracks and its preparation, can solve the problems of poor repair effect and large difference in component performance, and achieve the effect of reducing erosion and good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

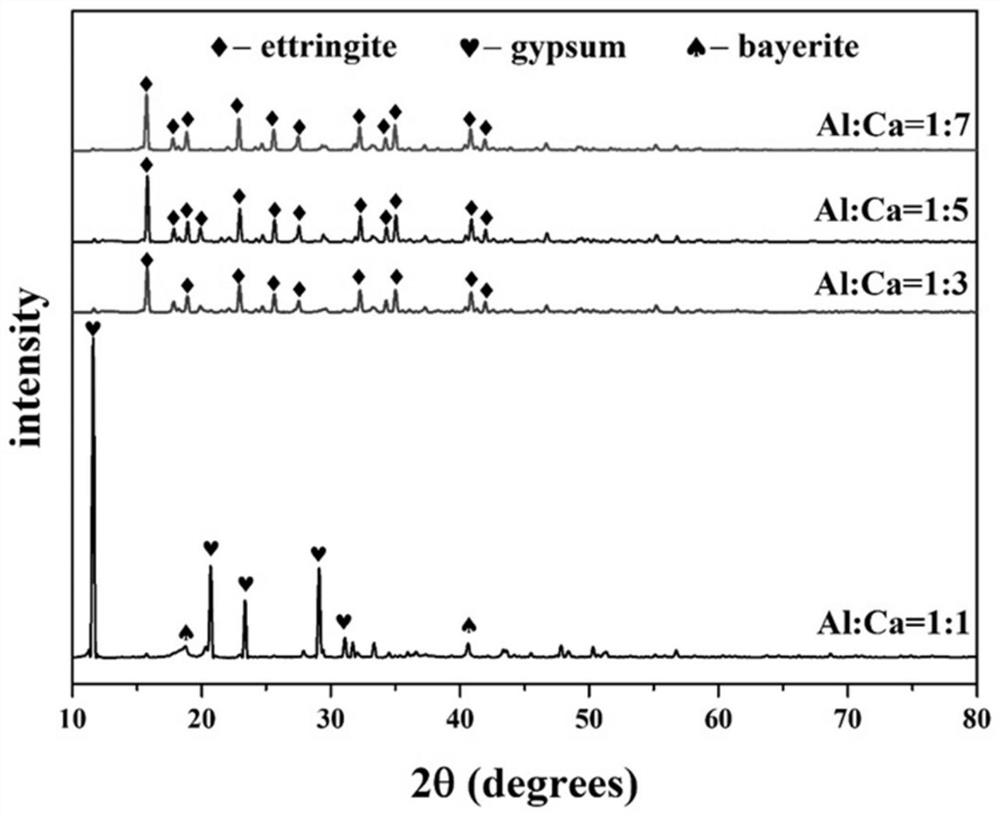

[0036] A solution for electrochemically repairing cracks in concrete. The solution is a composite electrolyte solution, which is prepared by mixing two solutions A and B in a certain proportion, wherein A solution is 0.1mol / l Ca(CH 3 COO) 2 ·H 2 O aqueous solution, B solution is 0.05mol / l Al 2 (SO 4 ) 3 18H 2 O aqueous solution, the preparation method for the solution of the electrochemical repair concrete crack comprises the following steps:

[0037] (1) A solution (Ca(CH 3 COO) 2 ·H 2 O aqueous solution) and B solution (Al 2 (SO 4 ) 3 18H 2 O aqueous solution);

[0038] (2) Mix A and B solutions at a volume ratio of 3:1, and stir evenly to obtain the product.

Embodiment 2

[0040] A solution for electrochemically repairing cracks in concrete. The solution is a composite electrolyte solution, which is prepared by mixing two solutions A and B in a certain proportion, wherein A solution is 0.1mol / l Ca(CH 3 COO) 2 ·H 2 O aqueous solution, B solution is 0.05mol / l Al 2 (SO 4 ) 3 18H 2 O aqueous solution, the preparation method for the solution of the electrochemical repair concrete crack comprises the following steps:

[0041] (1) A solution (Ca(CH 3 COO) 2 ·H 2 O aqueous solution) and B solution (Al 2 (SO 4 ) 3 18H 2 O aqueous solution);

[0042] (2) Mix A and B solutions at a volume ratio of 4:1, and stir evenly to obtain the product.

Embodiment 3

[0044] A solution for electrochemically repairing cracks in concrete. The solution is a composite electrolyte solution, which is prepared by mixing two solutions A and B in a certain proportion, wherein A solution is 0.1mol / l Ca(CH 3 COO) 2 ·H 2 O aqueous solution, B solution is 0.05mol / l Al 2 (SO 4 ) 3 18H 2 O aqueous solution, the preparation method for the solution of the electrochemical repair concrete crack comprises the following steps:

[0045] (1) A solution (Ca(CH 3 COO) 2 ·H 2 O aqueous solution) and B solution (Al 2 (SO 4 ) 3 18H 2 O aqueous solution);

[0046] (2) Mix A and B solutions at a volume ratio of 5:1, and stir evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com