Protein-rich cereal fermented yoghurt and preparation method thereof

A technology of yogurt and grain, applied in the field of grain fermented yogurt and its preparation, can solve the problems of strong starch texture, sour and rancid taste, etc., and achieve the effects of uniform softness, improved taste and stable texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

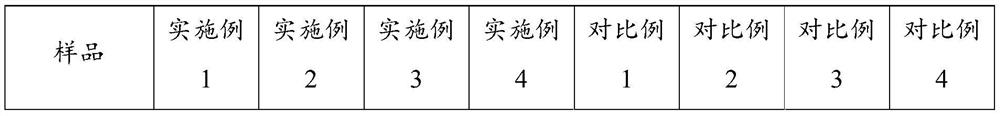

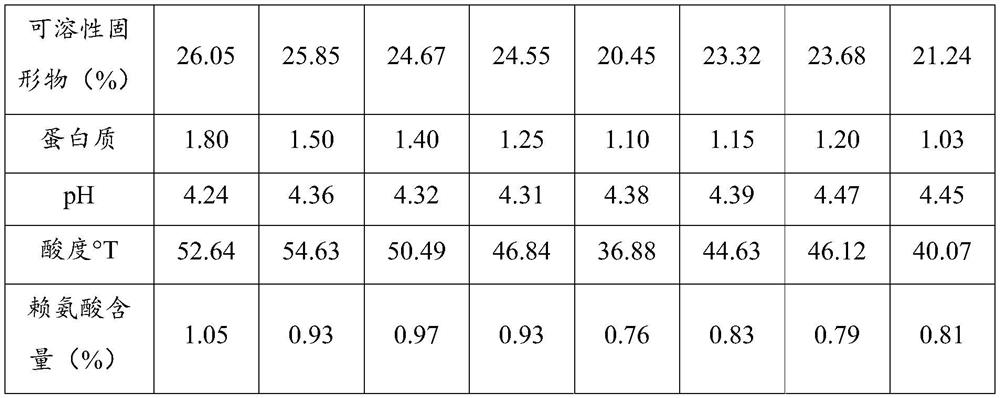

Examples

Embodiment 1

[0050] The grain fermented yoghurt of this embodiment comprises the following raw materials in percentage by weight: 55% of enzymolyzed oat pulp, 22% of enzymatically hydrolyzed quinoa pulp, 12% of wheat gluten powder, 5% of corn gluten powder, 5% of rice gluten powder, stabilizer 0.5% and yogurt starter 0.5%.

[0051] The preparation method of the cereal fermented yoghurt of the present embodiment comprises the following steps:

[0052](1) Mix 40g of oat flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain oat pulp, and mix 40g of quinoa flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain quinoa 4g corn gluten powder and pure water are mixed according to the ratio of material to liquid of 1:4g / ml to obtain corn gluten slurry, and 4g of rice gluten powder and pure water are mixed according to the ratio of material to liquid of 1:4g / ml to obtain The rice protein slurry was colloidally milled for 5 minutes, an...

Embodiment 2

[0058] The grain fermented yoghurt of this embodiment comprises the following raw materials in percentage by weight: 33% of enzymatic oat pulp, 33% of enzymatic quinoa pulp, 17% of wheat gluten powder, 8% of corn gluten powder, 8% of rice gluten powder, stabilizer 0.5% and yogurt starter 0.5%.

[0059] The preparation method of the cereal fermented yoghurt of the present embodiment comprises the following steps:

[0060] (1) Mix 40g of oat flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain oat pulp, and mix 40g of quinoa flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain quinoa Mix corn gluten powder and pure water according to the ratio of material to liquid of 1:4g / ml to obtain corn gluten slurry, and mix rice gluten powder and pure water according to the ratio of solid to liquid to 1:4g / ml to obtain rice protein slurry, carry out colloid milling 5min respectively, pass through 200 mesh sieves after col...

Embodiment 3

[0066] The cereal fermented yoghurt of this embodiment comprises the following raw materials in percentage by weight: 43% of enzymolyzed oat pulp, 28% of enzymolyzed quinoa pulp, 14% of wheat gluten powder, 7% of corn gluten powder, 7% of rice gluten powder, stabilizer 0.5% and yogurt starter 0.5%.

[0067] The preparation method of the cereal fermented yoghurt of the present embodiment comprises the following steps:

[0068] (1) Mix 40g of oat flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain oat pulp, and mix 40g of quinoa flour and pure water according to the ratio of material to liquid of 1:4g / ml to obtain quinoa Mix corn gluten powder and pure water according to the ratio of material to liquid of 1:4g / ml to obtain corn gluten slurry, and mix rice gluten powder and pure water according to the ratio of solid to liquid to 1:4g / ml to obtain rice protein slurry, carry out colloid milling 5min respectively, pass through 200 mesh sieves afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com