Intelligent environment-friendly forging forming equipment

A kind of forging molding and environmental protection technology, applied in the field of forging, can solve the problems of large equipment area, low control quality precision, unstable red punch quality, etc., achieve high degree of automation, avoid physical overwork, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

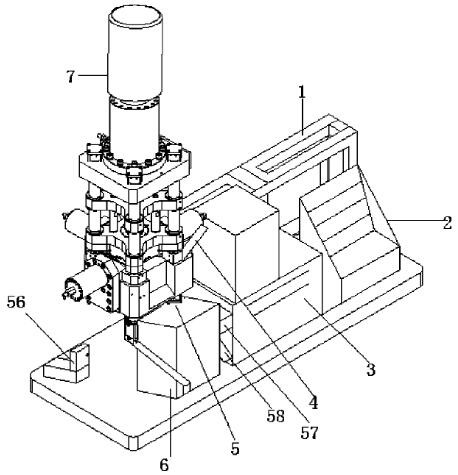

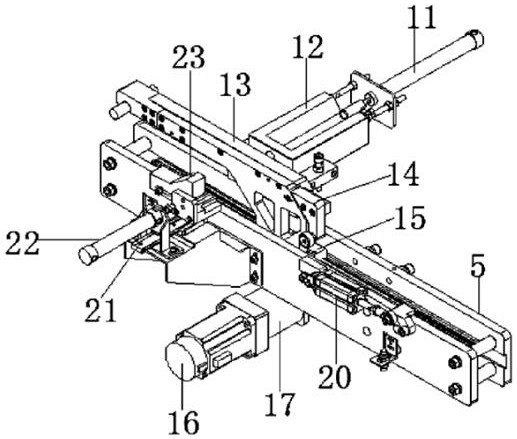

[0028] see figure 1 , 5 , 6, 7, 9, an intelligent and environmentally friendly forging equipment, including a frame 1, a red punching assembly 7 is fixed in front of the frame 1 by screws, a control box 56 is arranged under the left side of the red punching assembly 7, and the red punching assembly 7 Including: hydraulic cylinder a33, upper machine plate 34, sliding assembly a35, sliding assembly b36, core pulling assembly a37, core pulling assembly b38, mold fixing plate 39, air cylinder 40, upper mold top plate 41, spring 42, upper mold frame 43. Upper mold core 44, lower mold core 45, piston rod connecting plate 48, slider copper sleeve 49, slider bracket 50 and guide sleeve mold fixing plate 51, there is an upper machine plate 34 under the hydraulic cylinder a33, an upper machine plate There is a piston rod connecting plate 48 below the piston rod connecting plate 48, a movable component a is arranged below the piston rod connecting plate 48, a sliding component b36 is ar...

Embodiment 2

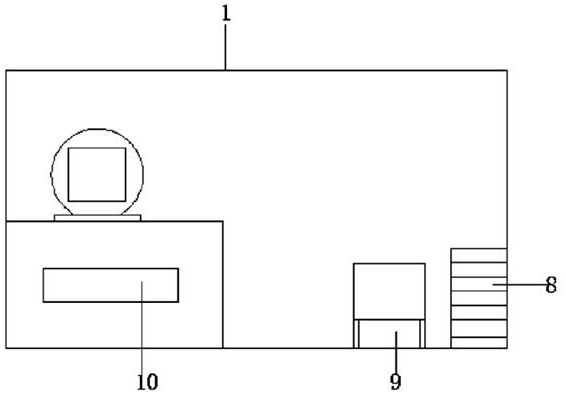

[0031] see figure 1 , 2 , 3, 4, 8, an intelligent and environmentally friendly forging equipment, including a baffle 8, the top of the control box 56 is fixed with the frame 1 by screws, the right side of the frame 1 has a workpiece conveying device assembly 5, above the workpiece conveying device assembly 5 There is a loading and unloading assembly 6, the loading and unloading assembly 6 is fixed on the red punching assembly 7 by screws, an intermediate frequency heating furnace assembly 3 is arranged behind the workpiece conveying device assembly 5, and between the intermediate frequency heating furnace assembly 3 and the workpiece conveying device assembly 5 is provided The chute device 4 is connected to the intermediate frequency heating furnace assembly 3 and the workpiece conveying device assembly 5 respectively. The left side of the chute device 4 is provided with an infrared temperature control detection probe 57, and the infrared temperature control detection probe 57...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com