Ladle flow control device for preventing molten steel from being solidified

A ladle and molten steel technology, applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of difficult control, molten steel pollution, and difficult judgment, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

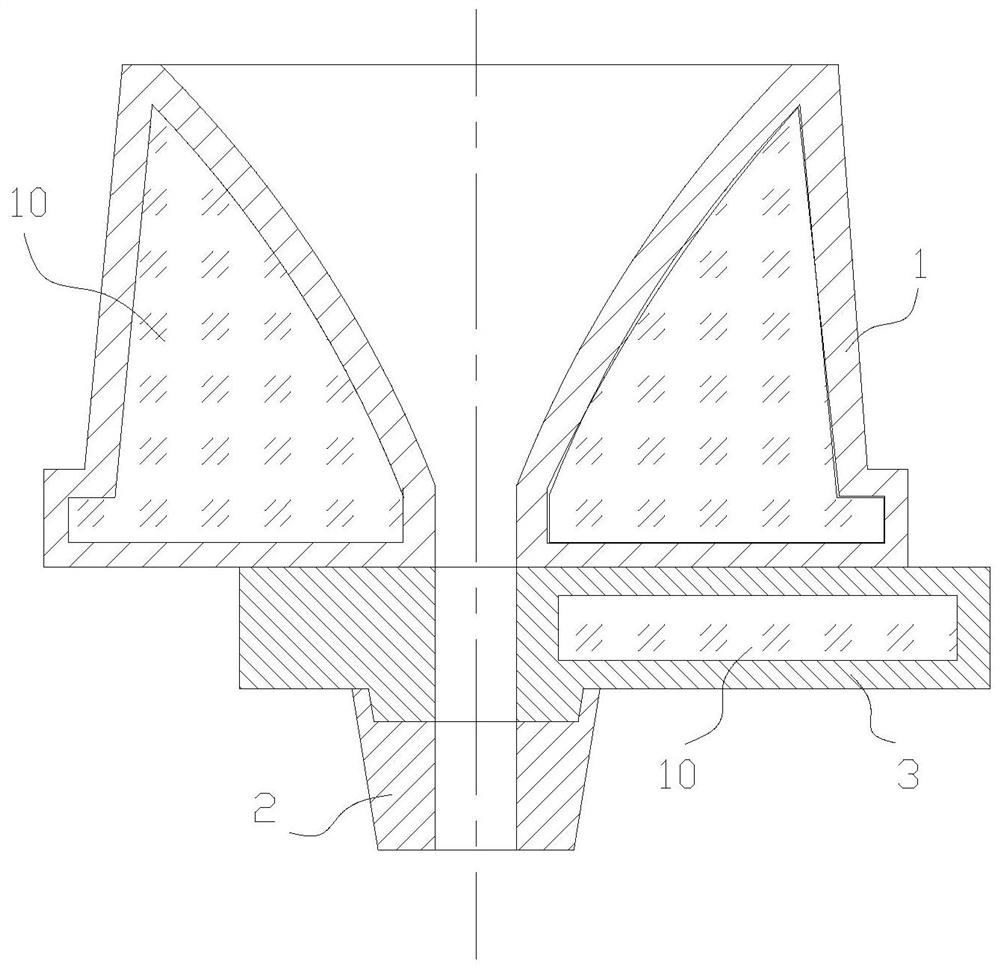

[0034] Such as figure 1 As shown, the heat insulation cavity 10 is filled with thermal insulation filler, the thermal insulation filler fills the thermal insulation cavity 10, and the thermal insulation filler is asbestos fiber. This embodiment can be used under the process condition that the residence time of molten steel in the ladle is less than or equal to 2h.

Embodiment 2

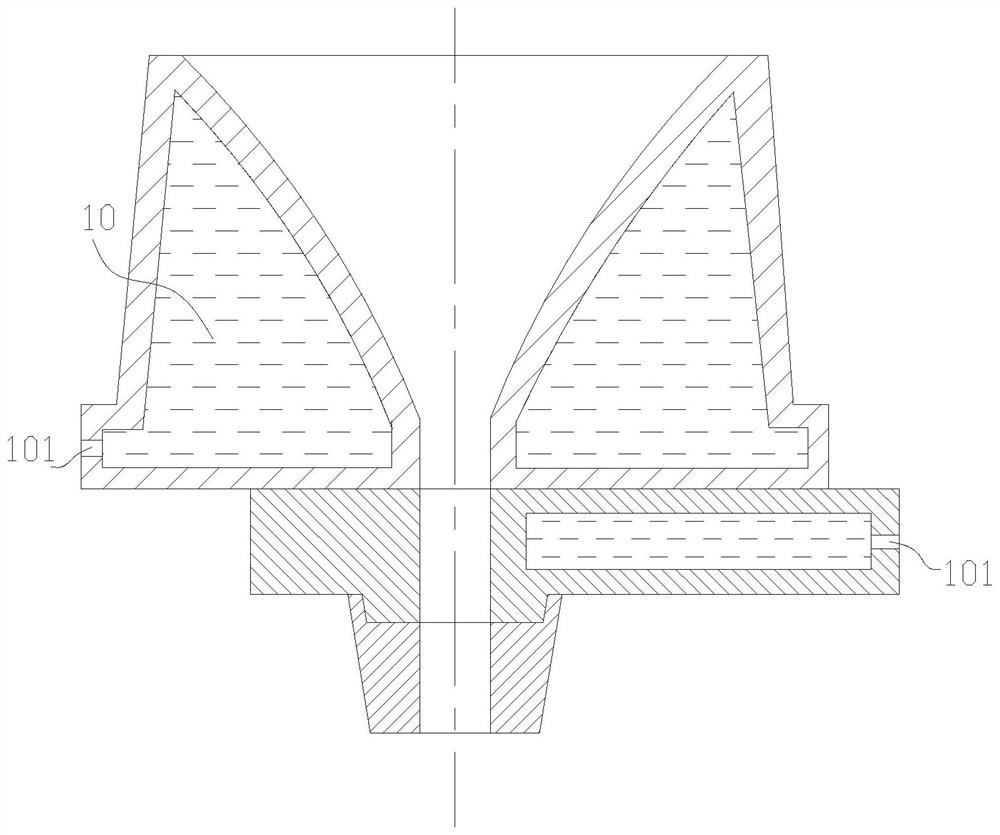

[0036] Such as figure 2 As shown, an air vent 101 is provided on the heat insulation cavity 10, and air is filled in the heat insulation cavity. The sides of the lower plate 3 are respectively provided with exhaust holes 101. When molten steel is loaded into the upper nozzle 1, the air can be discharged from the exhaust holes 101 after being heated and expanded to ensure that the pressure in the heat insulation chamber 10 is normal pressure. This embodiment can be used under the process condition that the residence time of molten steel in the ladle is 2-4h.

Embodiment 3

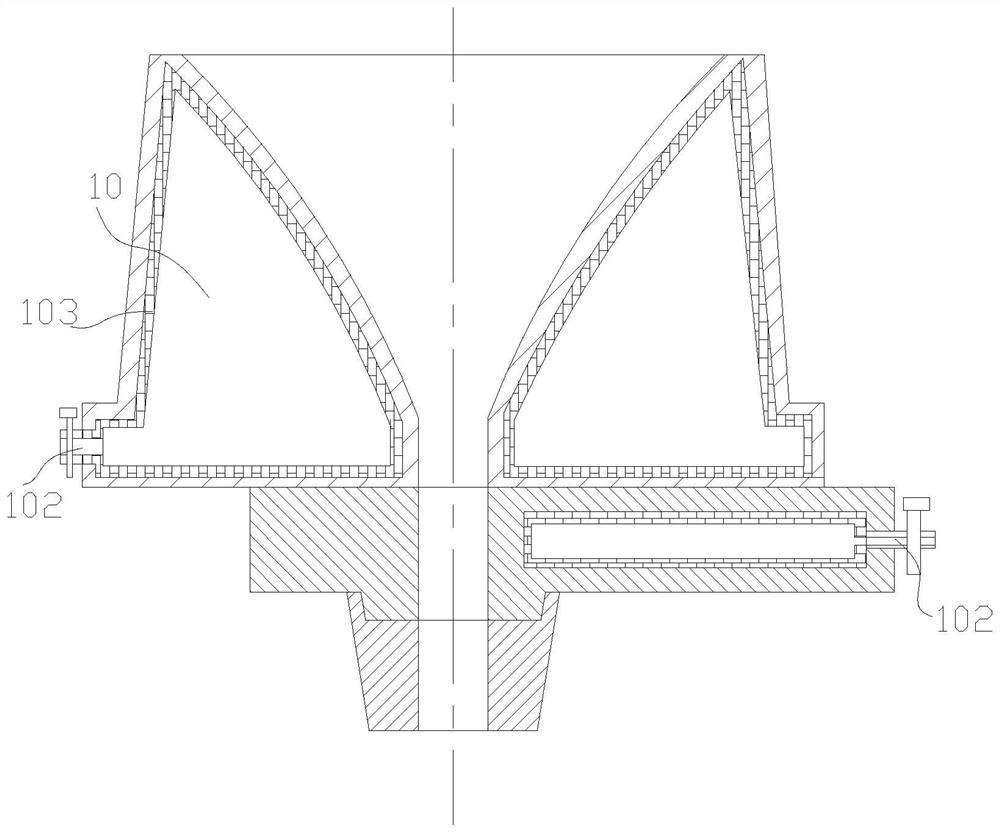

[0038] Such as image 3 As shown, the inside of the heat insulation chamber 10 is a vacuum, and an air nozzle 102 with a control valve is provided on the heat insulation chamber 10, and an air-proof layer 103 is fixed on the inner wall of the heat-insulation chamber 10, and the thickness of the air-proof layer 103 is 2-5mm. The materials include but are not limited to stainless steel, high-temperature refractory paint, etc. The purpose is to prevent external air from penetrating into the vacuum chamber through the upper nozzle 1 or the surface of the lower plate 3 after vacuuming, which will affect the vacuum degree. This embodiment can be used under the process condition that the residence time of molten steel in the ladle is 4-10h.

[0039] use as Figure 7For the corundum crucible of the size shown (its material meets the above requirements), the interlayer of the corundum crucible is filled with asbestos fibers, air and vacuumized respectively, and three kinds of heat pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com