Preparation method of concave fit mobile phone cover with texture diaphragm

A mobile phone cover and diaphragm technology, applied in the field of mobile phone covers, can solve the problems of light transmission, internal stress, optical distortion and other problems of the back cover of mobile phones, and achieve the effects of strong plasticity, good anti-aging performance, and low electromagnetic wave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention, and the technical solution of the present invention will be further described in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

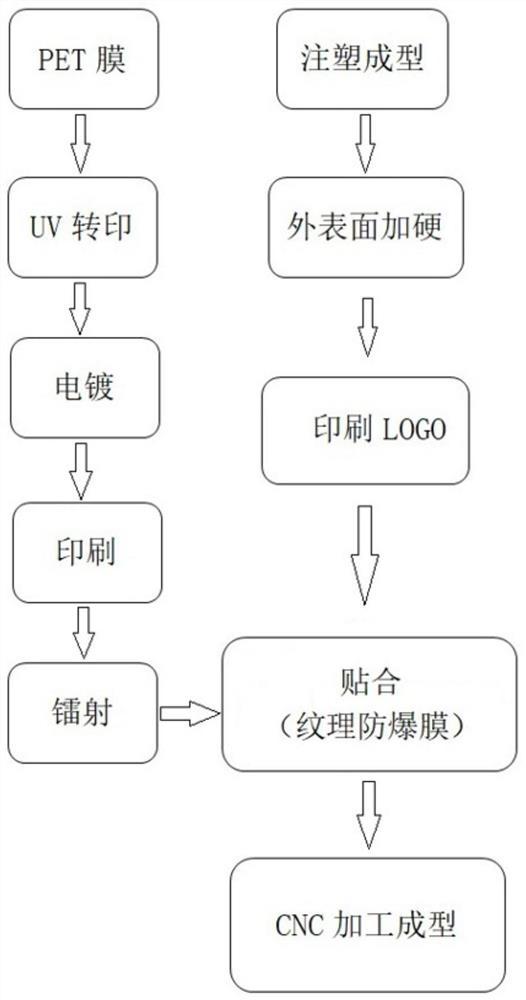

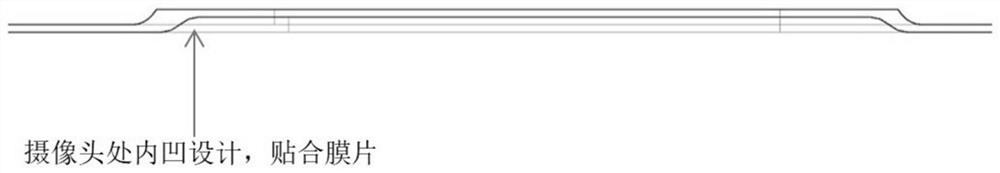

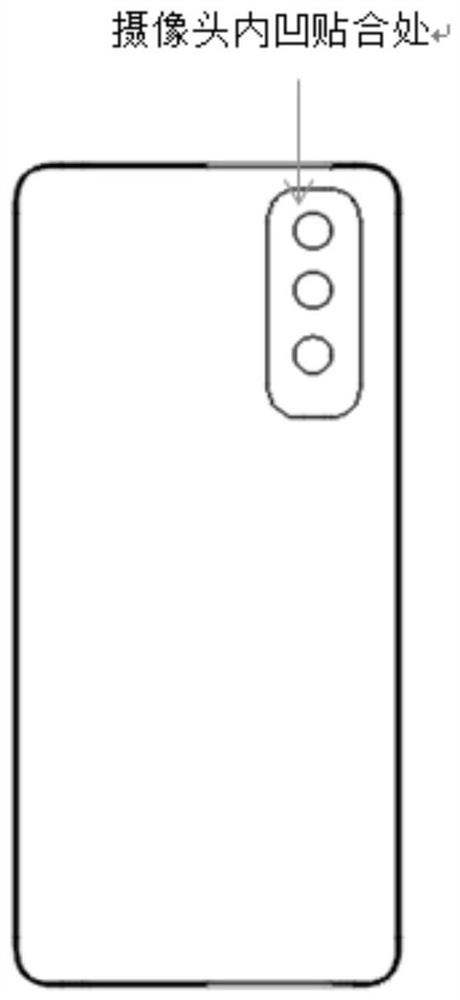

[0027] Such as Figures 1 to 3 As shown, a method for preparing a concave-fitted mobile phone cover of a textured diaphragm comprises the following steps:

[0028] S1) Injection molding: Injection molding with optical-grade transparent plastics. Injection molding includes the following process: plastic melting → upper mold → debugging → mold closing → injection filling → pressure-holding molding → cooling → mold opening; optical-grade transparent plastics For polymethyl methacrylate (PMMA) and / or polycarbonate (PC), the thickness of polymethyl methacrylate and / or polycarbonate after molding is 0.075-0.1mm; the injection pressure for injection filling is 80 -130MPa, the injection time is 2-5s, the pressure of the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com