Welding wire rod, manufacturing method thereof and welding method of welding wire rod and PCB

A welding method and manufacturing method technology, applied in the directions of printed circuit manufacturing, cable/conductor manufacturing, conductive core components, etc., can solve the problems of reduced production efficiency, high welding strength, increased cost, etc., to reduce labor intensity, High weld strength and the effect of improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

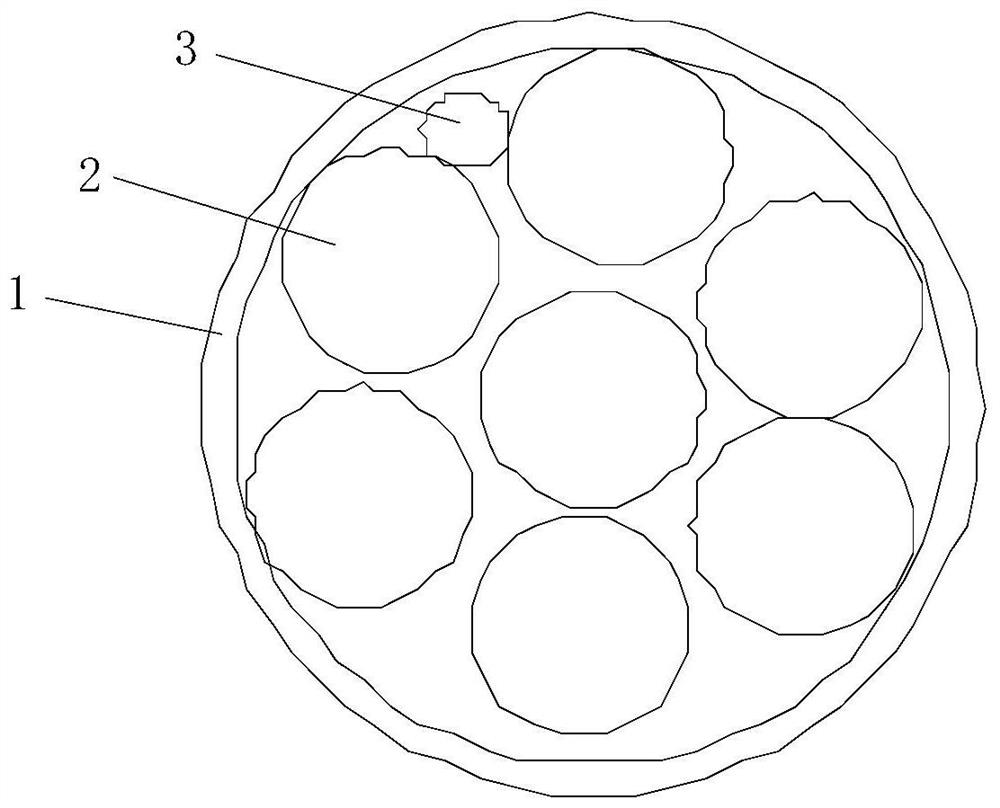

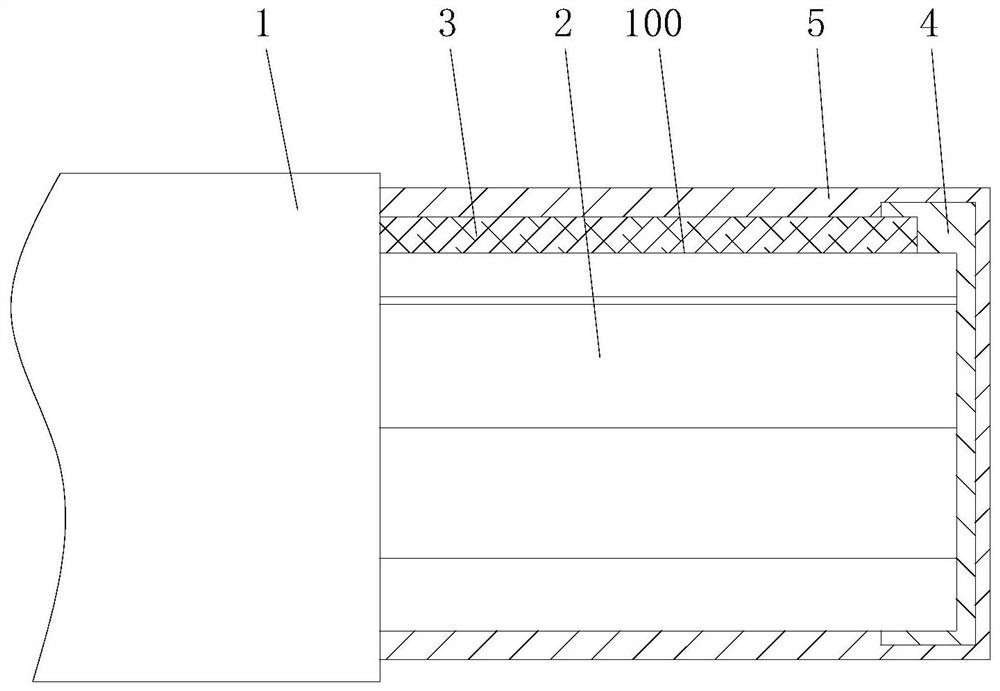

[0029] like figure 1 As shown, the welding wire of this embodiment includes an insulating sleeve 1 and a plurality of conductive cores 2 pierced in the insulating sleeve 1, and a heat-shrinkable fiber strip 3 is also worn in the insulating sleeve 1, and the conductive core 2 and The heat-shrinkable fiber strip 3 protrudes from one end of the insulating sleeve 1 to form an exposed welding part 100, and the exposed welding part 100 is divided into a middle section and an end section connected in sequence along the direction extending from the insulating sleeve 1, and the outer part of the end section The cladding is connected with the first cladding layer 4 formed by the first welding material, the first cladding layer 4 connects the conductive core 2 and the heat-shrinkable fiber strip 3 as a whole, and the conductive core 2 is connected in the first cladding layer 4. In the case of being connected with the heat-shrinkable fiber strip 3 as a whole, when the heat-shrinkable fibe...

Embodiment 2

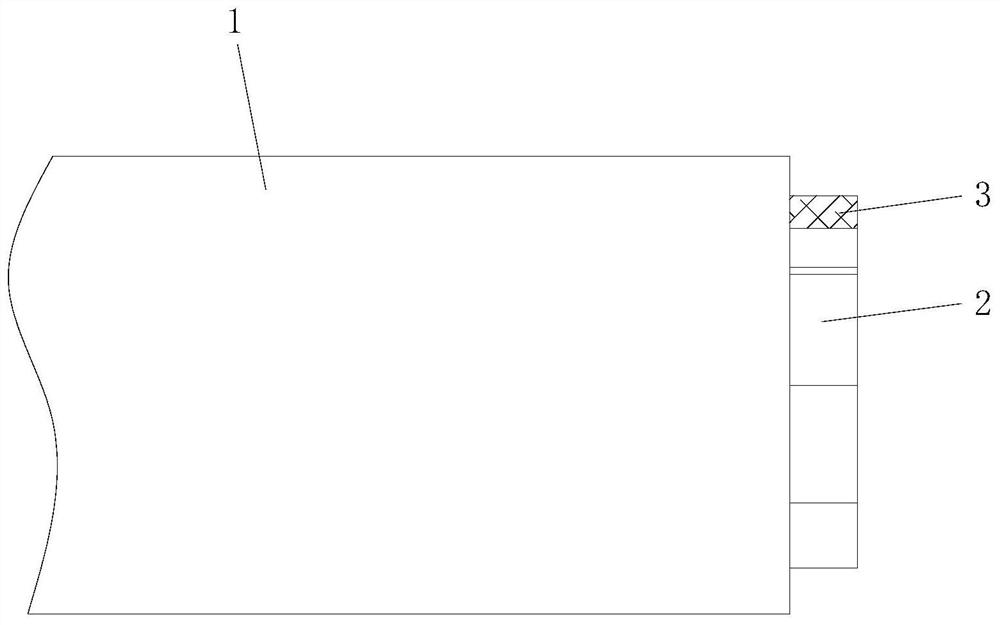

[0037] A method for manufacturing welding wires in Example 1, specifically, prefabricating a cable with a conductive core 2 and a heat-shrinkable fiber strip 3 in an insulating sleeve 1 (see image 3 ), first peel off a section of insulating sleeve 1 at one end of the cable to expose the end section of the exposed welding part 100, and coat and attach the first welding material to the outside of the conductive core 2 and the heat-shrinkable fiber strip 3 exposed at the end section Form the first cladding layer 4 (see Figure 4 ); Then, continue to strip off a section of insulating sleeve 1 so that the middle section of the exposed weld 100 is exposed (see Figure 5 ), the second welding material is coated and attached to the conductive core 2 and the heat-shrinkable fiber strip 3 of the middle section and the outside of the first cladding layer 4 to form the second cladding layer 5 (see figure 2 ). In the manufacturing method, a section of the insulating sleeve 1 is first s...

Embodiment 3

[0040] A welding method for welding the wire rod and the PCB board in Embodiment 1, the welding method is specifically, the end of the welding wire rod with the second cladding layer 5 is penetrated into the welding hole arranged on the PCB board body 6, and wave soldering is used The welding method is to weld and fix the welding wire rod and the PCB board body 6. The welding material used in wave soldering is the third welding material, and the melting point temperature of the third welding material is greater than the melting point temperature of the second welding material and the thermal shrinkage of the heat shrinkable fiber strip 3 The larger one of the deformation temperature, and the melting point temperature of the third welding material is lower than the melting point temperature of the first welding material. This welding method can make the first cladding layer 4 formed by the first welding material not melt and keep cladding and connecting the conductive core 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com