Epoxy resin copper-clad plate with high comparative tracking index suitable for PCB (Printed Circuit Board) manufacturing process and preparation method of epoxy resin copper-clad plate

A tracking index, epoxy resin technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve the effects of good flame retardancy, high tracking index, good toughness and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

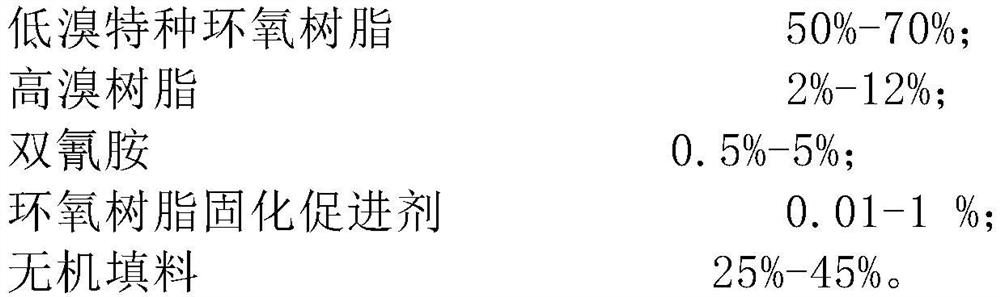

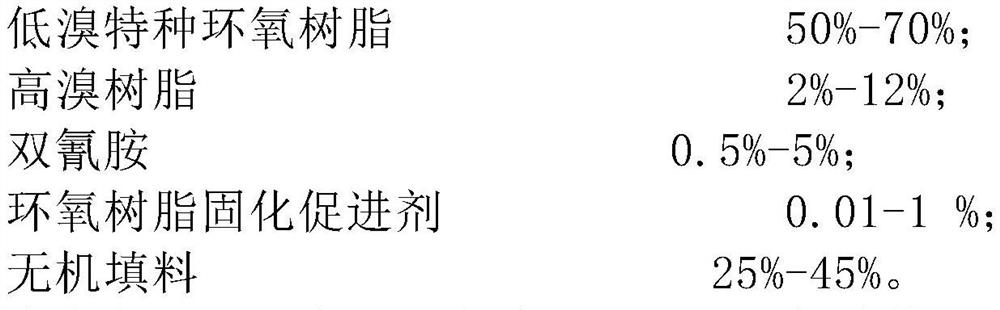

[0063] 1. The mass percent composition of the solids in the resin composition is 68%, and all the other are organic solvents (what this embodiment adopts is dimethylformamide), wherein, the formula of the solids is shown in the following table 1 (by weight ) as shown:

[0064] Table 1

[0065] raw material solid weight Low Bromine Specialty Epoxy Resin 58 High bromine resin 5 Dicyandiamide 1.5 Aluminum hydroxide 25 Silica powder 10 2MI 0.05

[0066] 2. Glue baking:

[0067] Prepreg gluing speed 13m / min;

[0068] 3. Prepreg control parameters:

[0069] Gel time 85 seconds;

[0070] Resin content 48.0%;

[0071] Resin fluidity 18%;

[0072] Volatile content 0.15%.

[0073] 4. Platen parameters:

[0074] Vacuum degree -0.085MPa;

[0075] Pressure 120-450psi;

[0076] Hot plate temperature 100-220℃;

[0077] Curing time >170°C for 35 minutes.

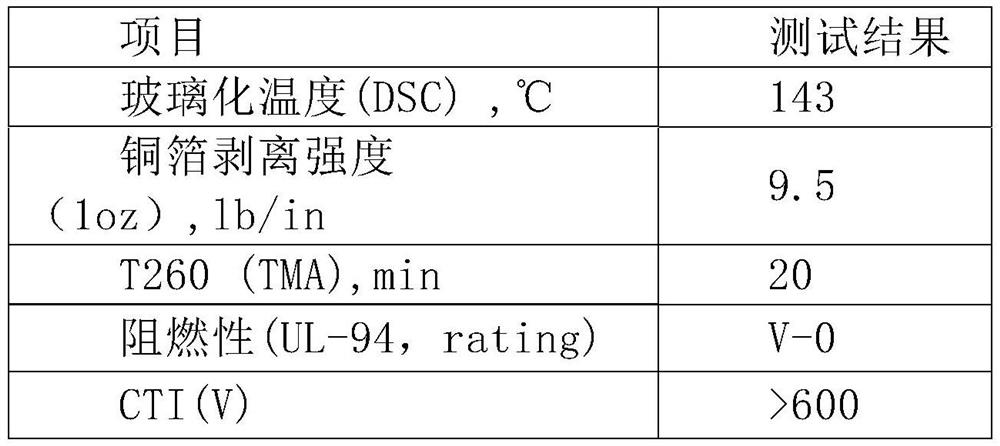

[0078] 5. The performance parameters of the substrate are shown in Table 2 be...

Embodiment 2

[0082] 1. the mass percent composition of the solids in the resin composition is 64%, and all the other are organic solvents (such as dimethylformamide), wherein, the formula of the solids is shown in the following table 3 (by weight):

[0083] table 3:

[0084] raw material solid weight Low Bromine Specialty Epoxy Resin 67 High bromine resin 3 Dicyandiamide 1.9 Aluminum hydroxide 20 Silica powder 8 2MI 0.05

[0085] 2. Glue baking:

[0086] Prepreg gluing speed 15m / min;

[0087] 3. Prepreg control parameters:

[0088] Gel time 95 seconds;

[0089] Resin content 48%;

[0090] Resin fluidity 22%;

[0091] Volatile content 0.11%.

[0092] 4. Platen parameters:

[0093] Vacuum degree -0.092MPa;

[0094] Pressure 120-500 psi;

[0095] Hot plate temperature 100-220℃;

[0096] Curing time >170°C for 36 minutes.

[0097] 5. The performance parameters of the substrate are shown in Table 4 (by weight):

[0098] Table 4

[...

Embodiment 3

[0101] 1. The mass percent composition of the solids in the resin composition is 62%, and all the other are organic solvents (such as dimethylformamide), wherein, the formula of the solids is shown in the following table 5 (by weight):

[0102] table 5

[0103] raw material solid weight Low Bromine Specialty Epoxy Resin 55 High bromine resin 9 Dicyandiamide 1.2 Aluminum hydroxide 30 Silica powder 12 2MI 0.05

[0104] 2. Glue baking:

[0105] Prepreg gluing speed 18m / min;

[0106] 3. Prepreg control parameters:

[0107] Gel time 102 seconds;

[0108] Resin content 49%;

[0109] Resin fluidity 18%;

[0110] Volatile content 0.13%.

[0111] 4. Platen parameters:

[0112] Vacuum degree -0.095MPa;

[0113] Pressure 120-500psi;

[0114] Hot plate temperature 100-220℃;

[0115] Curing time >170°C for 40 minutes.

[0116] 5. The performance parameters of the substrate are shown in Table 6:

[0117] Table 6

[0118]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com