Liquid microcapsule curing device and method based on infrared heating

A technology of microcapsule curing and infrared heating, applied in packaging and other directions, can solve the problems of low curing efficiency, irregular shape, cumbersome process, etc., and achieve the effect of uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

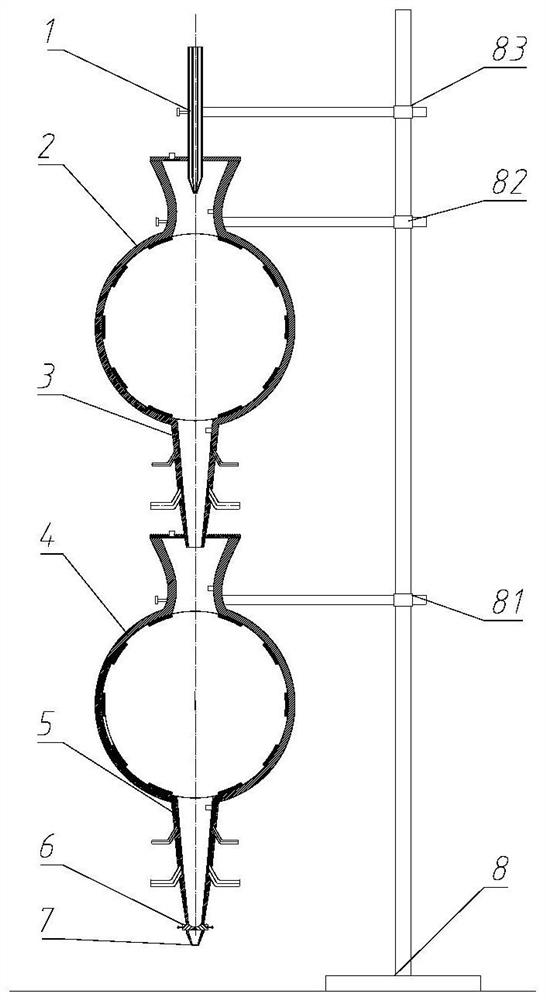

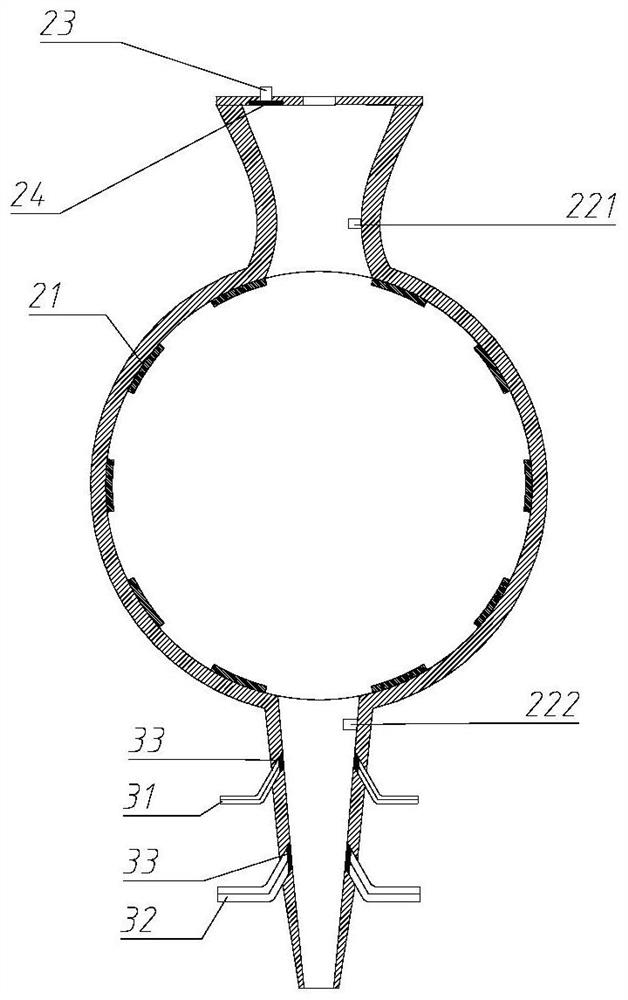

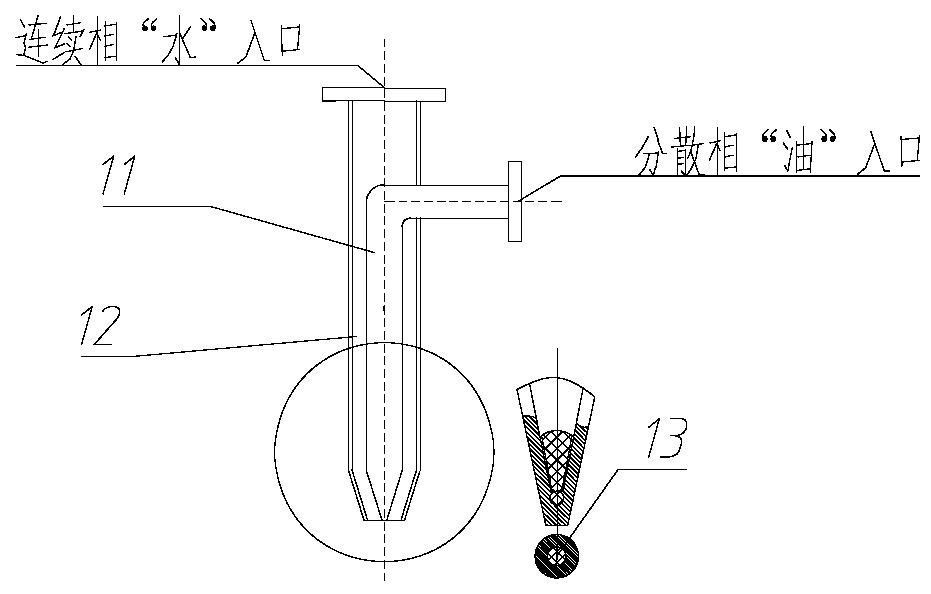

[0055] A liquid microcapsule curing device based on infrared heating, such as figure 1 As shown, the device includes: a coaxial dropper 1, a curing cavity 2 and an iron stand 8; the iron stand 8 is connected with a dropper clamp 83 and a curing cavity support clamp 82 through a vertical rod; the dropper Clip 83 is used to clamp the coaxial drip tube 1, and the curing cavity support clip 82 is used to clamp the curing cavity 2; the coaxial drip tube 1 and the curing cavity 2 The central axis coincides; the coaxial drip tube 1 extends into the curing cavity 2 from the opening at the top center of the curing cavity 2; the bottom center of the curing cavity 2 is provided with a discharge pipeline 3; the discharge pipeline 3 is provided with a discharge valve 6; the end of the discharge pipeline 3 is provided with a discharge port 7; the upper part of the curing cavity 2 is an inverted conical cavity with a hyperbolic section body, the top of the inverted tapered cavity of the cur...

Embodiment 2

[0073] This embodiment provides a liquid microcapsule curing method based on infrared heating, the method is applied to the liquid microcapsule curing device described in this method, and it is characterized in that the method includes the following steps:

[0074] Step 1: After fixing the coaxial dropper 1 and the curing cavity 2 respectively by using the dropper support clip 83 and the solidification cavity support clip 82 on the iron stand 8, close the unloading valve 6 and open the discharge valve 3 on the discharge pipe 3 A plurality of secondary air intake ducts 31 feed dry air into the device;

[0075] Step 2: The coaxial dropper 1 produces microcapsules 13, and when the microcapsules fall from the coaxial dropper 1 into the curing cavity 2 and pass through the first position sensor 221, a plurality of main air intake pipes are opened 32 and a plurality of infrared heating modules 21, the updraft generated by a plurality of main air intake ducts 32 prolongs the residenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com