Preparation method and application of anhydrous citric acid

A technology of anhydrous citric acid and citric acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as uneven distribution, affecting taste or utility, increasing production costs, etc., to improve temperature uniformity, Avoid the effect of excessive grain growth and reduce the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

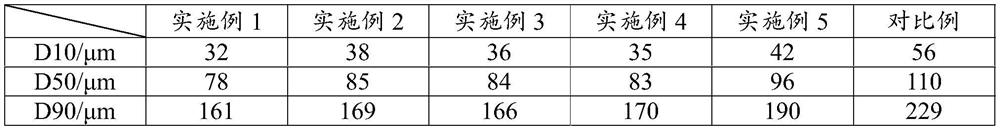

Examples

Embodiment 1

[0037] The preparation method of anhydrous citric acid is provided, comprising the following steps:

[0038] (1) Add citric acid into deionized water and heat to 90° C. to prepare a clear solution with a mass fraction of citric acid of 80%.

[0039] (2) Under the action of ultrasound, the clarified solution in step (1) was cooled to 84°C at a uniform speed to reach a state close to saturation, wherein the power of the ultrasound was 200W, the frequency was 20kHz, and the cooling time was 6min.

[0040] (3) Keep the ultrasonic effect unchanged, and carry out gradient cooling to the solution obtained in step (2) under negative pressure conditions; during the cooling process, the pressure is 15kPa; the initial cooling rate is 0.1°C / min, and the temperature drops every 10°C The rate drops by 0.01°C / min, and the temperature drops to 44°C.

[0041] (4) The product obtained in step (3) is centrifuged and dried to obtain anhydrous citric acid.

Embodiment 2

[0043] The preparation method of anhydrous citric acid is provided, comprising the following steps:

[0044] (1) Add citric acid into deionized water and heat to 90° C. to prepare a clear solution with a mass fraction of citric acid of 80%.

[0045] (2) Under the action of ultrasound, the clarified solution in step (1) was cooled to 84°C at a uniform speed to reach a state close to saturation, wherein the power of ultrasound was 300W, the frequency was 30kHz, and the cooling time was 6min.

[0046] (3) Keep the ultrasonic effect unchanged, and carry out gradient cooling to the solution obtained in step (2) under negative pressure conditions; during the cooling process, the pressure is 10kPa; The rate drops by 0.006°C / min, and the temperature drops to 44°C.

[0047] (4) The product obtained in step (3) is centrifuged and dried to obtain anhydrous citric acid.

Embodiment 3

[0049] The preparation method of anhydrous citric acid is provided, comprising the following steps:

[0050] (1) Add citric acid into deionized water and heat to 90° C. to prepare a clear solution with a mass fraction of citric acid of 80%.

[0051] (2) Under the action of ultrasound, the clarified solution in step (1) was cooled to 84°C at a uniform speed to reach a state close to saturation, wherein the power of ultrasound was 400W, the frequency was 20kHz, and the cooling time was 6min.

[0052] (3) Keep the ultrasonic effect unchanged, and carry out gradient cooling to the solution obtained in step (2) under negative pressure conditions; during the cooling process, the pressure is 15kPa; the initial cooling rate is 0.1°C / min, and the temperature drops every 10°C The rate drops by 0.01°C / min, and the temperature drops to 44°C.

[0053] (4) The product obtained in step (3) is centrifuged and dried to obtain anhydrous citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com