A kind of low temperature high strain rate superplastic medium manganese steel and preparation method thereof

A high strain rate, superplastic technology, applied in the field of high-strength steel, can solve the problems of low forming speed and high forming temperature, and achieve the effects of improving performance, realizing microstructure, and inhibiting the growth of grains

Active Publication Date: 2022-06-03

CHANGZHOU UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, the existing superplastic deformation conditions of medium manganese steel have two disadvantages: (1) the forming temperature is relatively high, often above 800°C; (2) the forming speed is low, and the strain rate is often 10 -3 Below / s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0046]

Embodiment 2

[0056] Step 6, critical heat treatment: the cold rolling is heated to 650° C., maintained for 5 min, and then water-cooled to room temperature.

[0060]

Embodiment 3

[0070] Step 6, critical heat treatment: the cold rolling is heated to 700° C., maintained for 4 min, and then water-cooled to room temperature.

[0074]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

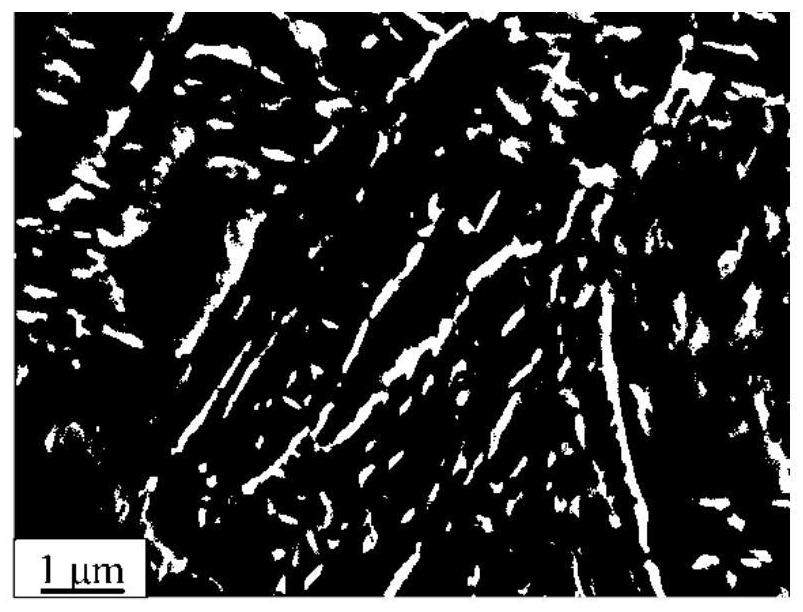

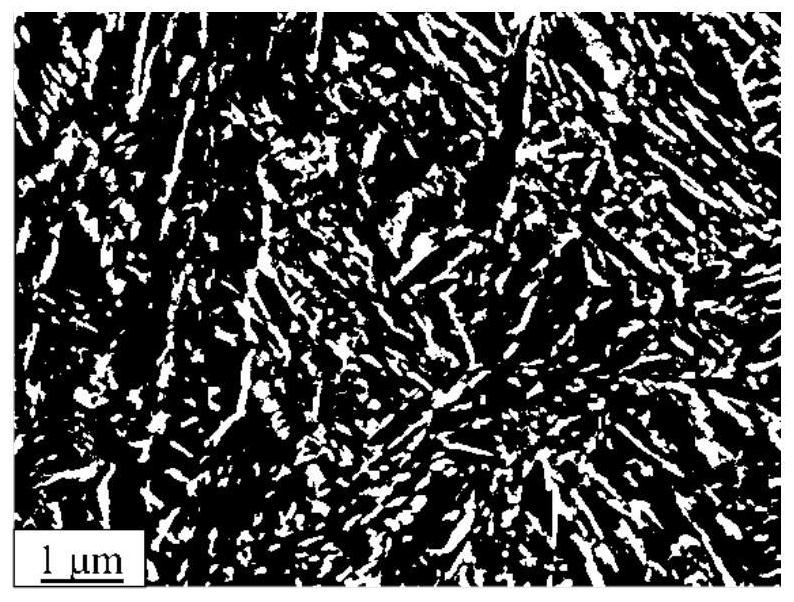

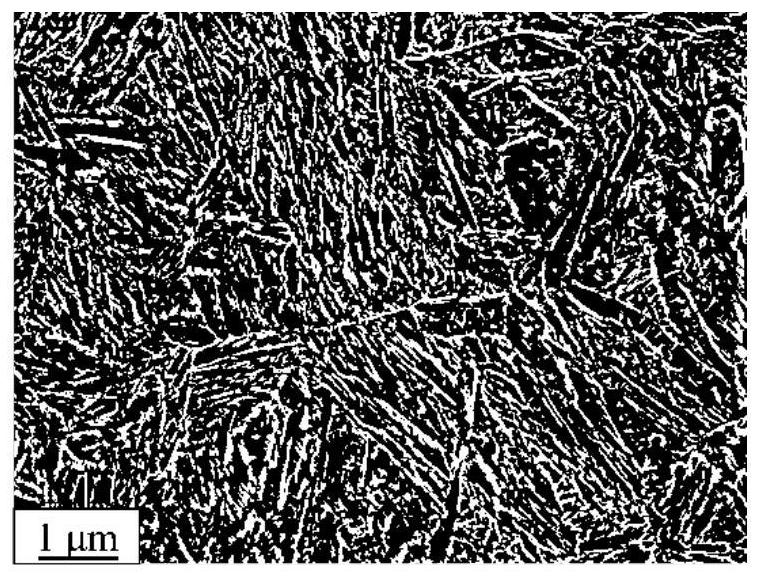

The invention discloses a low temperature high strain rate superplastic medium manganese steel and a preparation method thereof. The chemical composition of the medium manganese steel is calculated as: C: 0.05-0.15%; Mn: 5-8%; Al: 0-8%. 3%; Nb: 0.05-0.15%; V: 0.05-0.1%, the rest is Fe and unavoidable impurities; the medium manganese steel has a duplex austenite and ferrite microstructure, and the microstructure is uniform Equiaxed austenite and ferrite grains, the austenite and ferrite grain sizes are all below 0.3um. The preparation method of medium manganese steel is as follows: 1) smelting a steel ingot with a ratio of components, 2) heating forging, 3) low temperature hot rolling, 4) cyclic quenching heat treatment, 5) large reduction rate cold rolling, 6) critical heat treatment, and finally Obtain ultra-fine (average grain size less than 0.3 μm) austenite and ferrite dual-phase medium manganese steel plate.

Description

A kind of low temperature high strain rate superplastic medium manganese steel and preparation method thereof technical field The present invention relates to high-strength steel technical field, be specifically related to a kind of low temperature high strain rate superplastic medium manganese steel and its manufacture preparation method. Background technique In recent years, the rapidly developing automobile industry has brought a series of problems such as environmental pollution and energy shortage, environmental protection, Energy saving and safety have become the development themes of the automobile manufacturing industry. Among the many measures to save fuel consumption and reduce exhaust emissions, automobiles The effect of light weight is the most obvious. There are two main ways to reduce the weight of automobiles: one is to use lightweight materials, such as aluminum alloy, magnesium Alloys, engineering plastics and composite materials; the second is to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/04C22C38/06C22C38/12C21D8/02C21D1/18

CPCY02P10/20

Inventor 潘海军刘麟李京刘文明江鹏王知鸷吴王平苗乃明

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com