Composite magnetism gathering film

A thin-film and magnetic-gathering technology, applied in the field of magnetic-gathering materials, can solve the problems of high cost, difficult to achieve thickness, stress accumulation concentration and lattice defects, and achieve the effect of final cost reduction and convenient regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

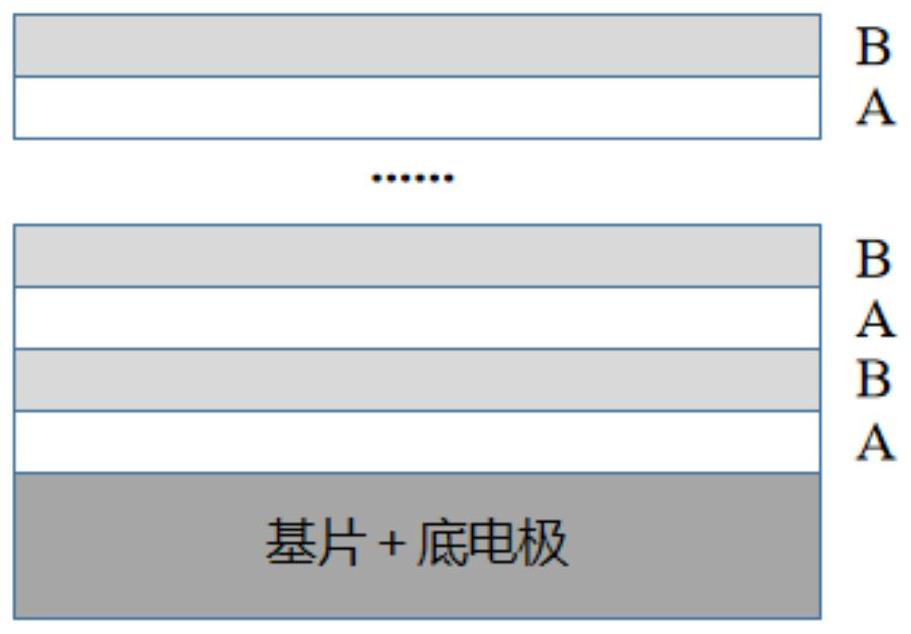

[0043] In the polymagnetic film of the present embodiment, the first electroplating film A is amorphous Ni x FE y Mo z Thin film, 73 x FE y Mo z Compound ratio close to Ni 78 FE 17 Mo 5 The second electroplated film B is a Cu film, 5 repeated stacks; single layer Ni 78 FE 17 Mo 5 The film has a thickness of 3 μm, a single layer Cu film having a thickness of 50 nm, and the first electroplating film A and the second electroplated film B are alternately stacked 5 times to obtain a composite magnetine film.

[0044] The specific steps of electroplating are as follows:

[0045] Step 1: After 10% of the dilute hydrochloric acid having a concentration of 10%, the plated substrate was immersed for 10 min, washed with deionized water, and then drying it with nitrogen after rinse;

[0046] Step 2: Configure electroplating Ni 78 FE 17 Mo 5 Electrolyte, this example Ni 78 FE 17 Mo 5 The component of the electrolyte is: 1-butyl-dodecyl-3-methylmy Chloride 25 g / L, hexahydrate sulfate 50 g / ...

Embodiment 2

[0052] The difference from the first embodiment is that the first electroplating film A is a polystrial Ni x FE y Mo z Thin film, Ni x FE y Mo z Compound ratio close to Ni 30 FE 43 Mo 27 Ni x FE y Mo z The proportion of X X is greatly improved, Ni x FE y Mo z The film is mainly based on polysone. Can be feso in the electrolyte 4 · 7h 2 The concentration of O is set to 4 ~ 6g / L to increase the X value, and the specifically can be adjusted according to the actual component test results.

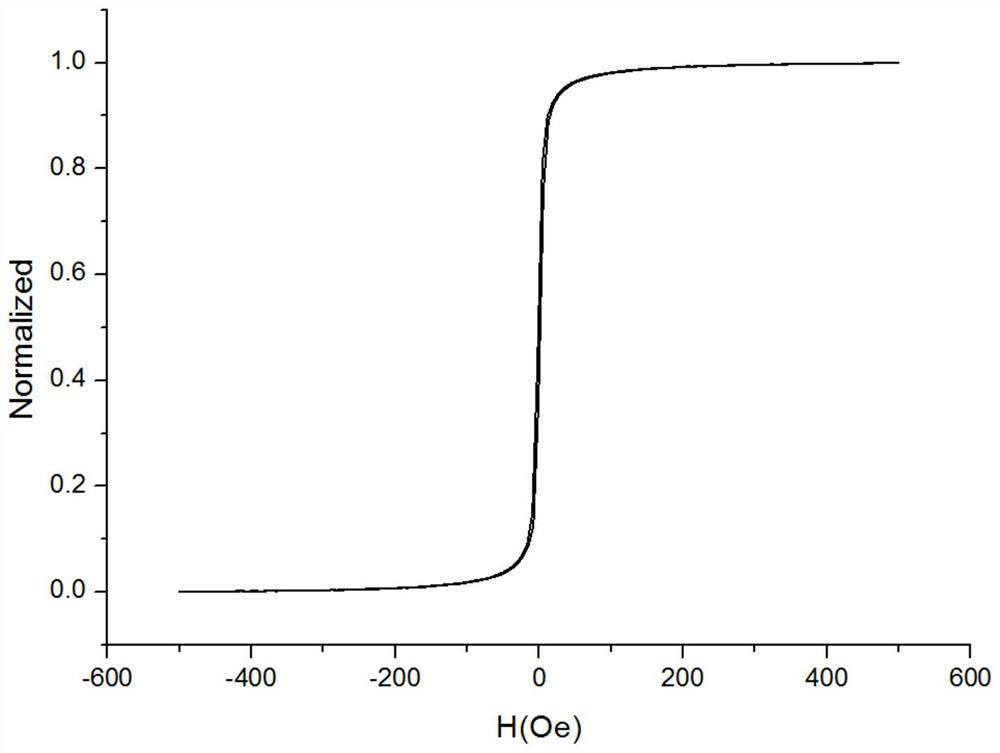

[0053] The composite magnetine film of Example 2 was hysteresissed, and Hes and the face corresponding to the face c It is 0.6OE and 0.9OE; the corresponding face and the facade are fitted within ± 5OE and ± 2400oE range, and its non-linearity is within 2%, and the outgoing linear response range is effective, which can be satisfied. High requirements for the performance requirements of the magnetic flux aggregator.

Embodiment 3

[0055] The difference from the first embodiment is that the first electroplating film A is a polystrial Ni x FE y Mo z Thin film, Ni x FE y Mo z Compound ratio close to Ni 75 FE 15 Mo 10 Film, second electroplating film B is amorphous Ni x FE y Mo z Thin film, Ni x FE y Mo z Compound ratio close to Ni 78 FE 17 Mo 5 . Can be feso in the electrolyte 4 · 7h 2 The concentration of O is set to 2 to 3 g / L, and the electrolyte pH is set to 3 to 4, the electroplating temperature is 30 ° C, and the value of X, Y, Z is adjusted according to the actual component test results.

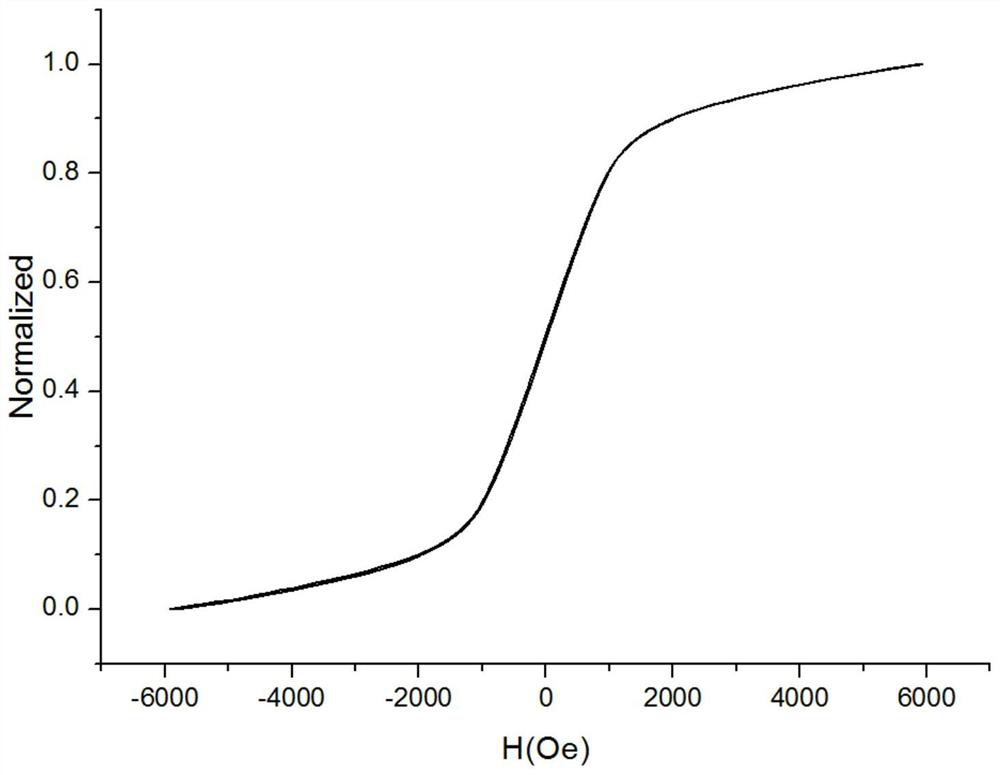

[0056] The composite polymer magnetism test obtained in Example 3 was magnetically resistant to the test results. Figure 3A and Figure 3B As shown, the HC corresponding to the face and the face is 0.4OE and 0.7OE, respectively; the corresponding face and the face are fitted within ± 4OE and ± 1600oE range, and its non-linearity is within 2%, effectively broadening The outdoor linear response range is met to meet the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com