Chitin and derivative antibacterial cloth thereof as well as preparation method and application of chitin and derivative antibacterial cloth

A derivative, chitin technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of insufficient practical application, low mechanical strength, difficulty in taking into account lightness, softness, flexibility, etc., and achieve good Antibacterial function, environmental protection effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

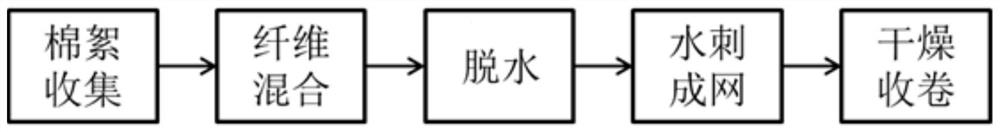

[0041] This example provides a kind of preparation method of chitin and its derivative antibacterial cloth, the preparation method of this chitin and its derivative antibacterial cloth comprises the steps:

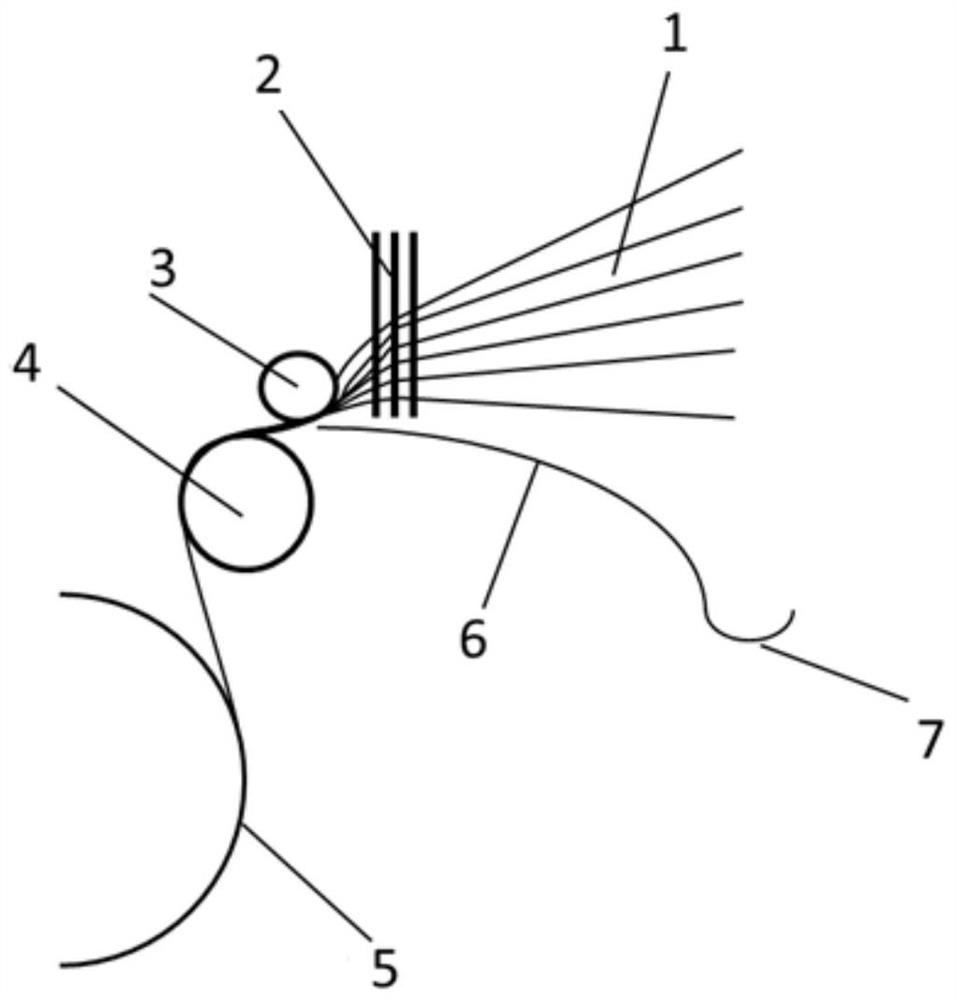

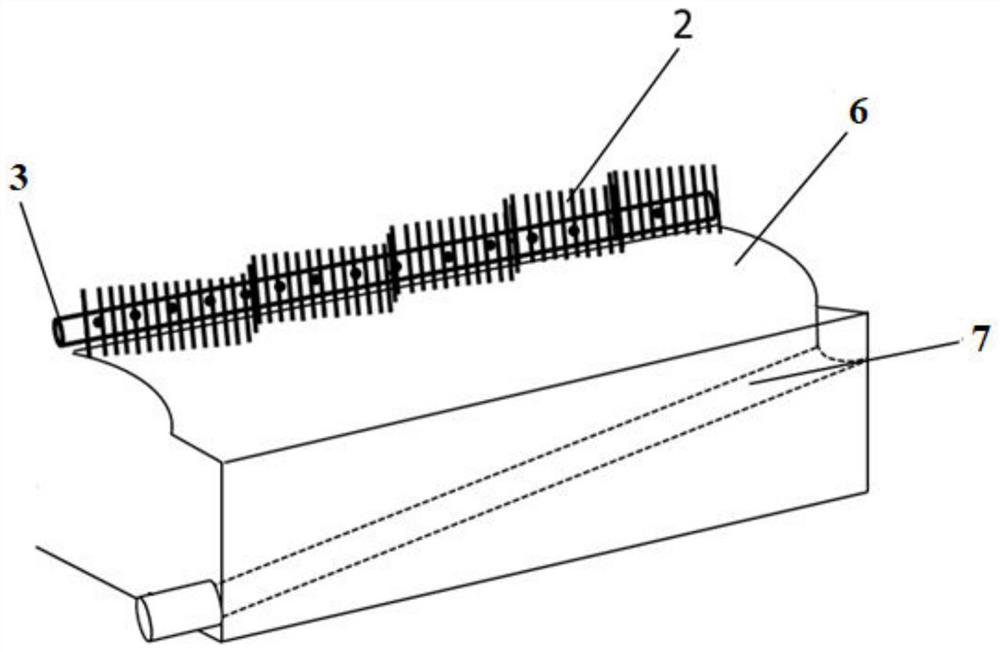

[0042] During the warping process of the cotton yarn passing through the dividing reed, the flowing water is used to continuously spray the reed hole through which the cotton yarn passes through the dividing reed, and the cotton yarn and the cotton wadding screened out by the dividing reed on the cotton yarn are soaked. Wet, collect the cotton wadding after soaking, the wadding includes short fibers and flying flowers;

[0043] Mix the soaked cotton wool and chitin fiber (commercially purchased, fineness: 2-3.6dtex, fiber length: 30-100mm) in water, and then output it to the dehydration area in the form of a plane, and form a net through spunlace after dehydration. Dried to make chitin and its derivatives antibacterial cloth.

[0044] In this example, in terms of mass per...

Embodiment 2

[0062] Basically the same as Example 1, the only difference is that the chitin fiber is replaced by chitosan fiber (fineness: 1-2.7dtex fiber length: 35-75mm).

Embodiment 3

[0064] Basically the same as Example 1, the only difference is: in terms of mass percentage, in the antibacterial cloth of chitin and its derivatives, chitin fiber accounts for 50%, and cotton wool accounts for 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com