Hidden water purification drainage ditch and construction method thereof

A construction method and drainage ditch technology, applied in the direction of separation methods, drainage structures, chemical instruments and methods, etc., can solve problems such as breeding bacteria and mosquitoes, affecting urban sanitation, waterlogging disasters, etc., to prevent pollution transfer, ensure safe use, The effect of water quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

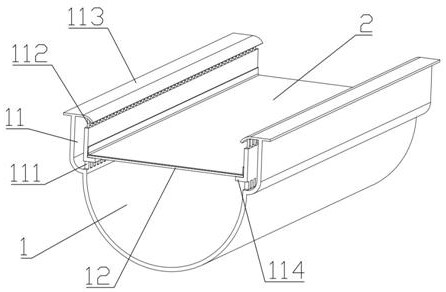

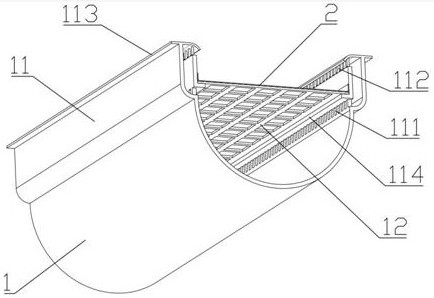

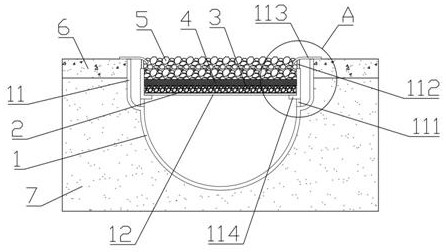

[0044] The embodiment of the present invention discloses a concealed water purification drainage ditch, referring to Figure 1-4 , including a drainage ditch body 1, the top of the drainage ditch body 1 is laid with water filtering stones, the drainage ditch body 1 is arranged in the base soil layer 7, the top of the drainage ditch body 1 is flat with the tops of the LID facilities 6 on both sides, The middle layer of the drainage ditch body 1 is provided with a support filter plate 12, and the support filter plate 12 divides the drainage ditch body 1 into two parts: the top filter layer and the bottom excess water layer, and the water filter stones include fine filter gravel 3 and rough filter gravel5.

[0045] A method for constructing a concealed clean water drainage ditch, comprising the following construction steps:

[0046]Step 1: Calculate the required cross-sectional area of the drainage ditch according to the local precipitation intensity and precipitation. The gre...

Embodiment 2

[0052] Increase on the basis of embodiment 1:

[0053] refer to Figure 1-4 , the two sides of the top of the drain body 1 are provided with overflow plates 11, a water tank is formed between the overflow plate 11 and the drain body 1, and the top of the water tank passes through the top water screen 112 and the filter layer The bottom of the water tank communicates with the water holding layer through the bottom water screen 111 .

[0054] The gutter body 1 and the overflow plate 11 are made of metal or reinforced concrete.

[0055] refer to image 3 and 4 , the filter layer also includes a filter cover soil 4, the filter cover soil 4 is arranged between the fine filter gravel 3 and the coarse filter gravel 5, and the coarse filter gravel 5 is at the top.

[0056] Coarsely filtered crushed stone 5 is located near the top water screen 112, and its top exceeds the water screen 112 and is flush with the top of the LID facility 6 ground, and the bottom extends into the follow...

Embodiment 3

[0061] Increase on the basis of embodiment 1 or 2:

[0062] When excavating the earthwork, a bucket with the same cross-sectional shape as the drainage ditch body 1 is used, and a one-time plowing and digging method is adopted.

[0063] The leveling treatment in step 2 includes removing floating soil and filling sand for leveling, and the horizontal straightness of the base is detected before the leveling treatment.

[0064] When sand filling is leveled, a tamper with the same shape as the base is used for tamping, or a roller with the same shape as the base is used for rolling and tamping.

[0065] Before installing the drain body 1, transport the drain body 1 to the side of the base groove and apply waterproof glue on the interface.

[0066] After the installation is complete, apply sealant to the gap and level the surface.

[0067] The fine filter gravel 3 and the coarse filter gravel 5 are cleaned and screened before laying, and the filter covering soil is laid between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com