Guniting slurry ground surface to underground conveying system

A conveying system and surface technology, applied in underground chambers, wellbore linings, shaft equipment, etc., can solve the problems of hidden traffic safety hazards, pollution of the surface and underground environment, high vehicle transportation costs, and reduce manual work and mechanized work. The effect of high degree and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

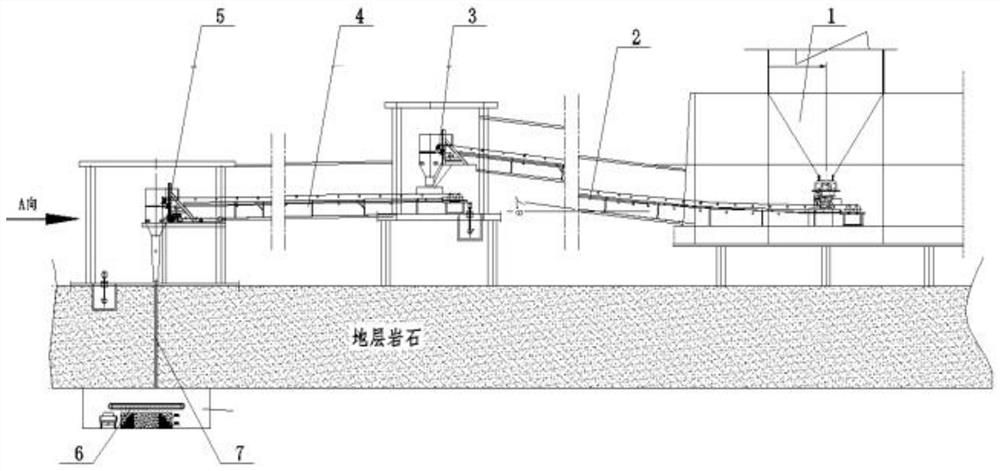

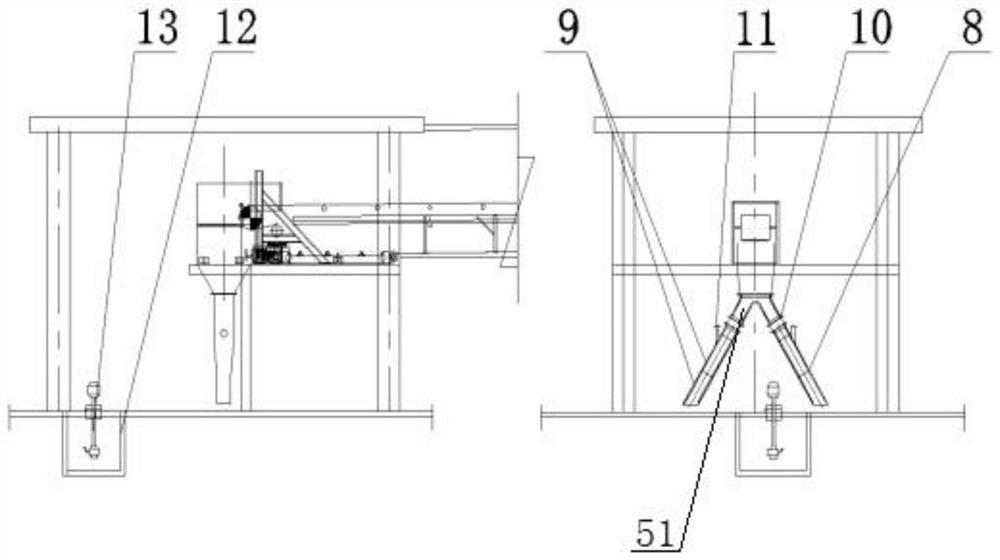

[0028] From Figure 1-4 It can be seen that a slurry surface of the present embodiment is a downhole transport system, including a stirring station 1, and the output of the stirring station 1 is connected to the first tape engine transport corridor 2, the first tape engine transport corridor 2 The output terminal is connected to the intermediate transfer station 3, and the output of the intermediate transfer station 3 is connected to the second tape engine transport corridor 4, and the output end of the second tape engine transport corridor 4 is connected to the lower body bucket device 5;

[0029] The output end of the lower body bucket device 5 is connected to the pore structure 7, and the output end of the echoleum structure 7 extends to the downhole and connected to the downhole transport station 6.

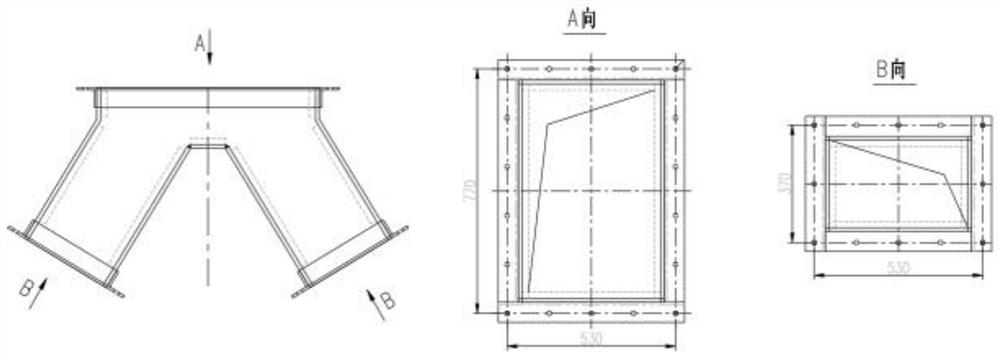

[0030] A double-port funnel 51 is provided at the lower body opening position of the lower body bucket device 5, and the output end of the double-port funnel 51 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com