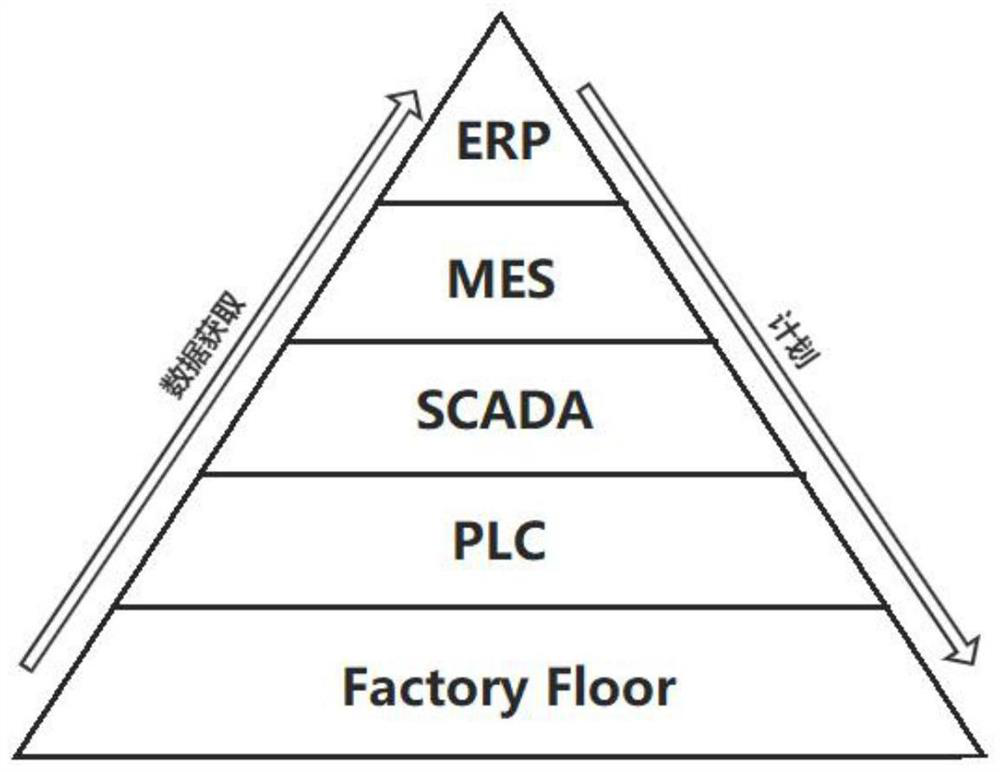

Personalized customization flexible production line information system architecture

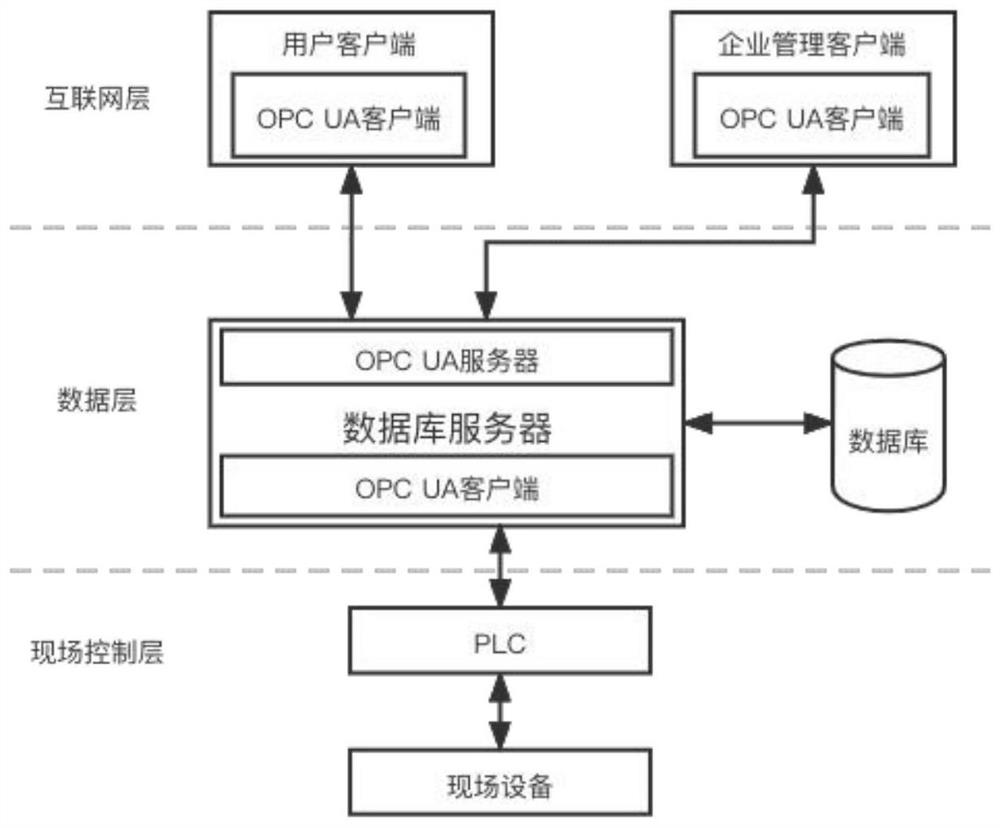

A flexible production line and information system technology, applied in the direction of manufacturing computing system, comprehensive factory control, electrical program control, etc., can solve the problem that DCOM cannot use Internet communication, etc., to improve scalability and maintainability, simplify architecture, reduce operation Dimension cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

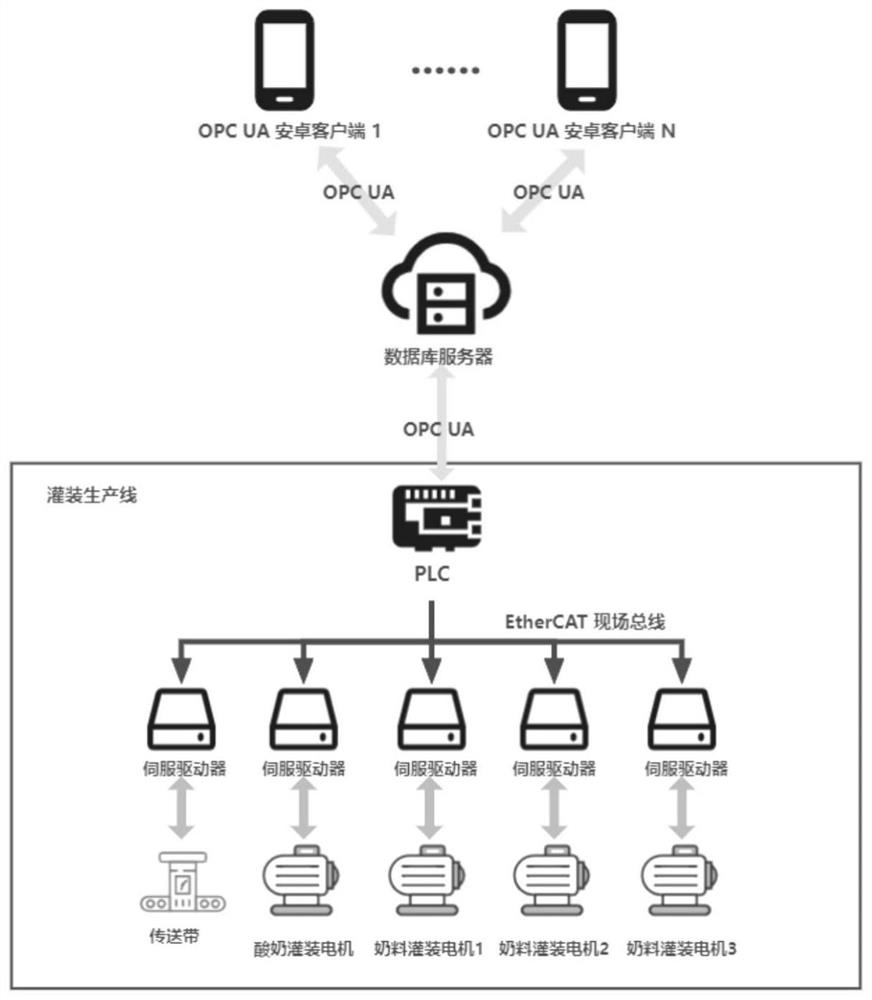

[0050] Such as Figure 4 As shown, the single production process of canned beverages is described as follows:

[0051] 1. The user places an order for filling beverages on the Android mobile phone, and the ingredient data (production request information) is packaged via the OPC UA client through the control interaction module of the mobile phone.

[0052] 2. The OPC UA client establishes a connection with the OPC UA server in the database server through the connection module. Temporarily store the production request information in the node created in the OPC UA server at the current moment.

[0053] 3. The database server sends the production request information to the cloud database at this time, and the cloud database stores the production request information persistently. At the same time, an OPC UA client is created to communicate with the PLC in the field control layer, and the production request information is sent to The on-site control layer, so that the on-site cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com