Annealing method and annealing device of PERC battery

An annealing device and annealing technology, applied in the field of solar cells, can solve the problems of more attenuation of the average conversion efficiency of the cell, poor LID uniformity of the cell, and reduced carrier life, so as to improve the anti-LID performance, improve the conversion efficiency, The effect of promoting passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

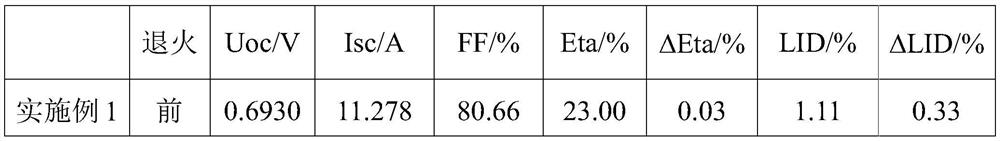

Embodiment 1

[0057] This embodiment provides an annealing method for a PERC battery, the annealing method comprising the following steps:

[0058] (1) preheating the battery sheet containing the passivation film to obtain a heat-treated battery sheet; in the preheating treatment, the first temperature zone is the area where the front side of the battery is preheated, and the temperature is 420 ° C, and the second The temperature zone is the area where the back of the battery is preheated, and the temperature is 360°C;

[0059] (2) Light-treat the heat-treated battery sheet obtained in step (1) for 15 seconds at a temperature of 180°C. The light source for the light treatment is an LED light source with a wavelength of 580nm and an intensity of 84kW / m 2 , the output power is 70%; then cooling treatment is carried out for 10s until the end point temperature is 40°C to obtain an annealed battery sheet.

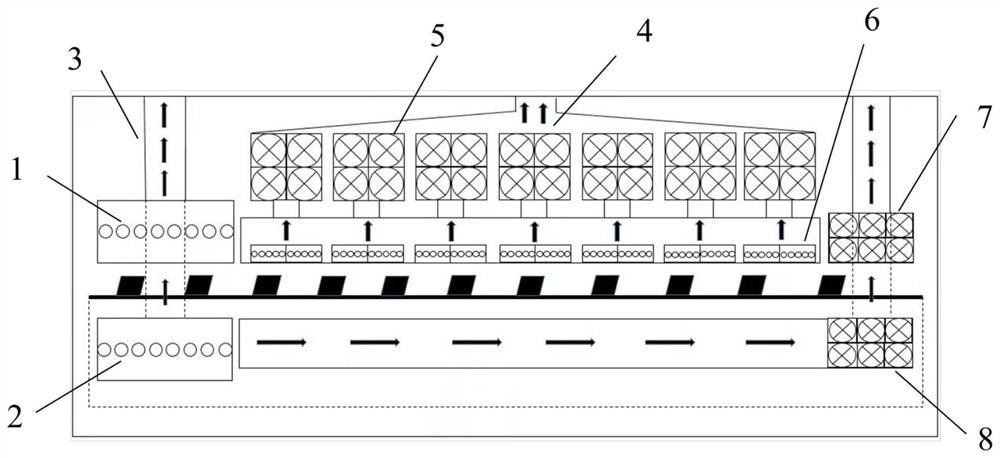

[0060] This embodiment also provides an annealing device for a PERC battery, such as fi...

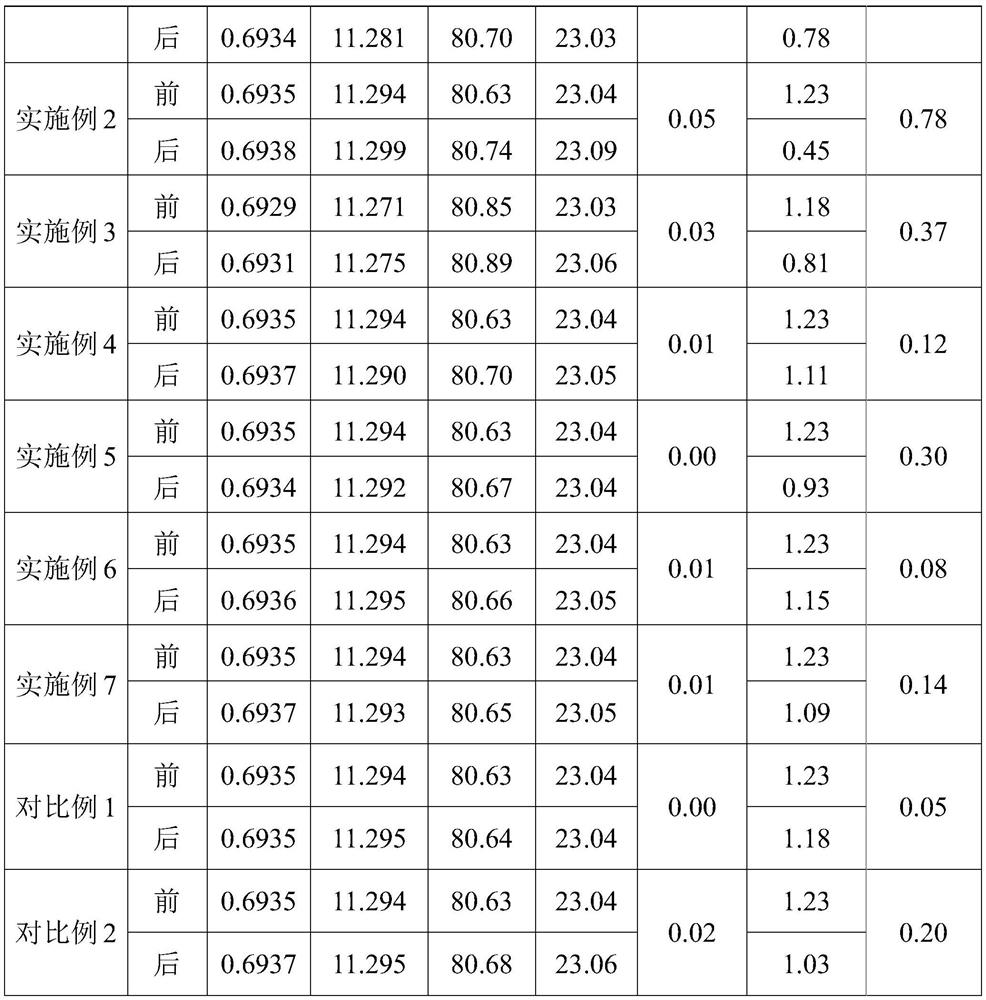

Embodiment 2

[0065] This embodiment provides an annealing method for a PERC battery, the annealing method comprising the following steps:

[0066] (1) preheating the battery sheet containing the passivation film to obtain a heat-treated battery sheet; in the preheating treatment, the first temperature zone is the area where the front side of the battery is preheated, and the temperature is 440 ° C, and the second The temperature zone is the area where the back of the battery is preheated, and the temperature is 380°C;

[0067] (2) Light-treat the heat-treated battery sheet obtained in step (1) for 18 seconds at a temperature of 210°C. The light source for the light treatment is an LED light source with a wavelength of 587nm and an intensity of 96kW / m 2 , the output power is 80%; then cooling treatment is carried out for 13s until the final temperature is 45°C to obtain an annealed battery sheet.

[0068] This embodiment also provides an annealing device for the PERC battery as described i...

Embodiment 3

[0070] This embodiment provides an annealing method for a PERC battery, the annealing method comprising the following steps:

[0071] (1) preheating the battery sheet containing the passivation film to obtain a heat-treated battery sheet; in the preheating treatment, the first temperature zone is the area where the front of the battery is preheated, and the temperature is 460 ° C, and the second The temperature zone is the area where the back of the battery is preheated, and the temperature is 400°C;

[0072] (2) Light-treat the heat-treated battery sheet obtained in step (1) for 20 seconds at a temperature of 240° C., and the light source for the light treatment is an LED light source with a wavelength of 595 nm and an intensity of 108 kW / m 2 , the output power is 90%; then cooling treatment is carried out for 15s until the final temperature is 50°C to obtain an annealed battery sheet.

[0073] This embodiment also provides an annealing device for the PERC battery as describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com