Preparation method and application of autologous fatty acid protein milk

A technology of fatty acid and protein milk, applied in the field of preparation of autologous fatty acid protein milk, can solve the problem that the utilization value of adipose tissue is not reflected in the clinic, and achieve the effect of promoting repair and reducing pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

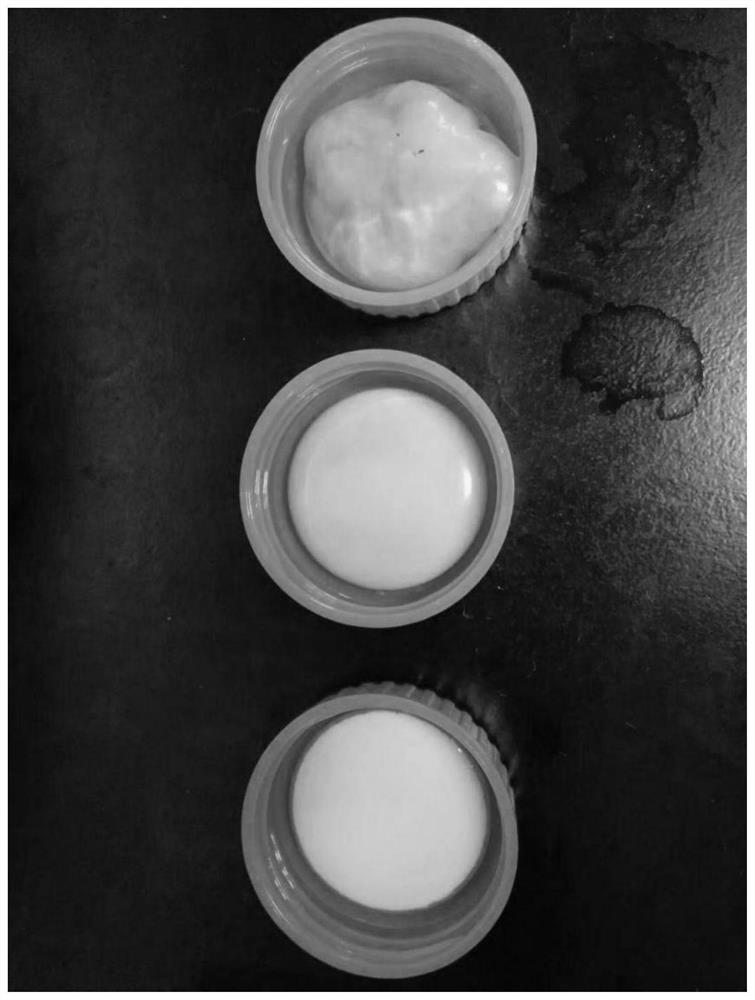

[0028] A kind of preparation method of autologous fatty acid protein milk

[0029] Take 200g of human adipose tissue, first remove the larger cord structure in the adipose tissue, let it stand to remove swelling fluid or centrifuge to remove water, and then mix the adipose tissue with PRP-platelet rich plasma at a solid-liquid ratio of 2:1 mg / mL The tissue mixture was obtained, and the tissue mixture was ground for 3 minutes. The tissue grinding condition was 50 Hz, 40 s, and 3 cycles until the tissue mixture reached a homogeneous milky white color. The ground tissue mixture was placed in an ultrasonic breaker, and the tissue The mixture is placed in a centrifuge tube, and the centrifuge tube is placed in ice cubes for ultrasonic emulsification, and the amplitude of the ultrasonic vibration is set to 50 Hz for ultrasonic emulsification, so as to obtain the autologous fatty acid protein milk product.

Embodiment 2

[0031] A kind of preparation method of autologous fatty acid protein milk

[0032] Take 200g of human adipose tissue, first remove the large cord structure in the adipose tissue, let it stand to remove swelling fluid or centrifuge to remove water, and then mix the adipose tissue and active components at a solid-liquid ratio of 4:7 mg / mL to obtain the tissue mixture,

[0033] The mixing volume ratio of 10% glutathione and 10% tranexamic acid in the active component is 2:5;

[0034] The obtained tissue mixture was ground for 1 min. The tissue grinding condition was 60 Hz, 30 s, and 3 cycles until the tissue mixture reached a homogeneous milky white color. The ground tissue mixture was placed in an ultrasonic breaker, and the tissue mixture was placed in a In a centrifuge tube, the centrifuge tube is placed in ice cubes for ultrasonic emulsification, and the amplitude of ultrasonic vibration is set to 40 Hz for ultrasonic emulsification to obtain autologous fatty acid protein mi...

Embodiment 3

[0036] A kind of preparation method of autologous fatty acid protein milk

[0037] Take 200g of human adipose tissue, first remove the larger cord structure in the adipose tissue, let it stand to remove swelling fluid or centrifuge to remove water, and then mix the adipose tissue with the active component at a solid-liquid ratio of 3:10 mg / mL to obtain the tissue mixture,

[0038] The mixing volume ratio of PRP-platelet-rich plasma, 15% glutathione and 15% tranexamic acid in the active component is 2:3:5;

[0039] The obtained tissue mixture was ground for 3 min, and the tissue grinding condition was 60 Hz, 40 s, 4 cycles, until the tissue mixture reached a homogeneous milky white color, and the ground tissue mixture was placed in an ultrasonic breaker, and the tissue mixture was Put it in a centrifuge tube, place the centrifuge tube in ice cubes for ultrasonic emulsification, set the amplitude of ultrasonic vibration to 50 Hz for ultrasonic emulsification, and obtain the aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com