Coating mixing device for water pump production line and mixing method thereof

A technology of mixing device and production line, applied in the field of paint mixing device for pump production line, can solve the problems of paint heating, affecting the cleaning effect of the inner wall of the mixing tank, and high paint viscosity, and achieving the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

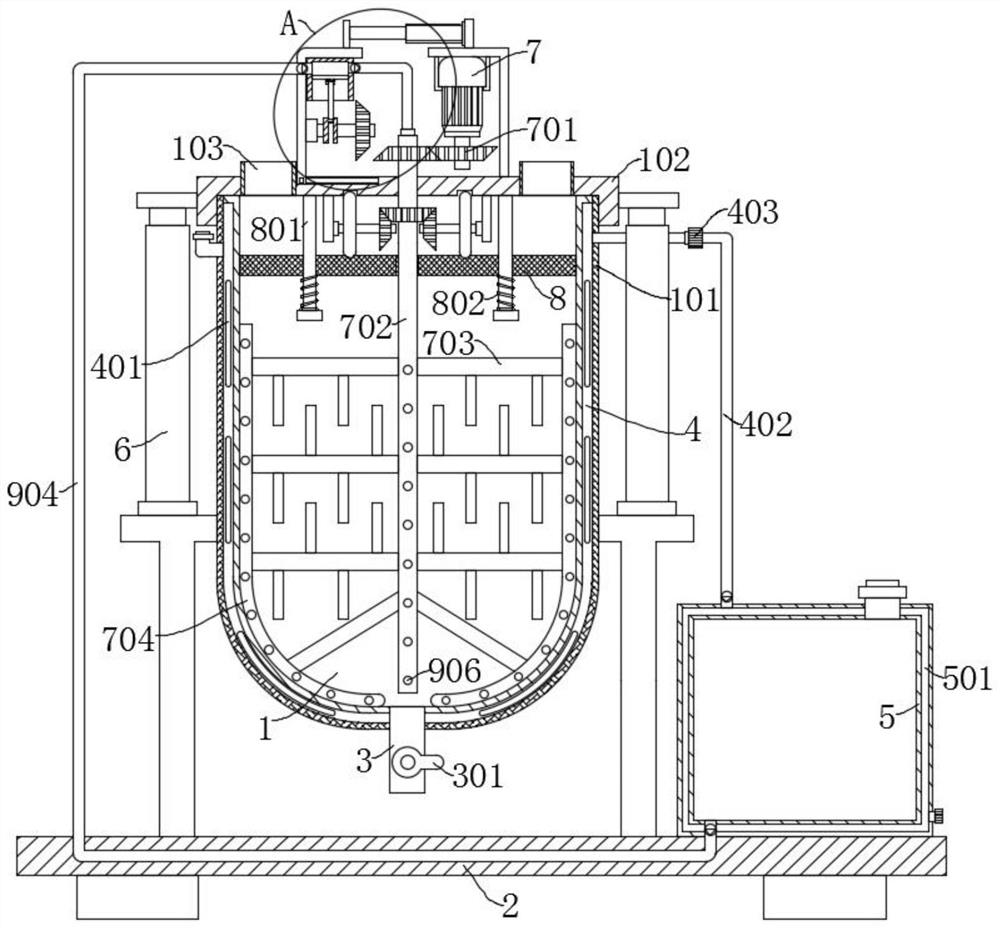

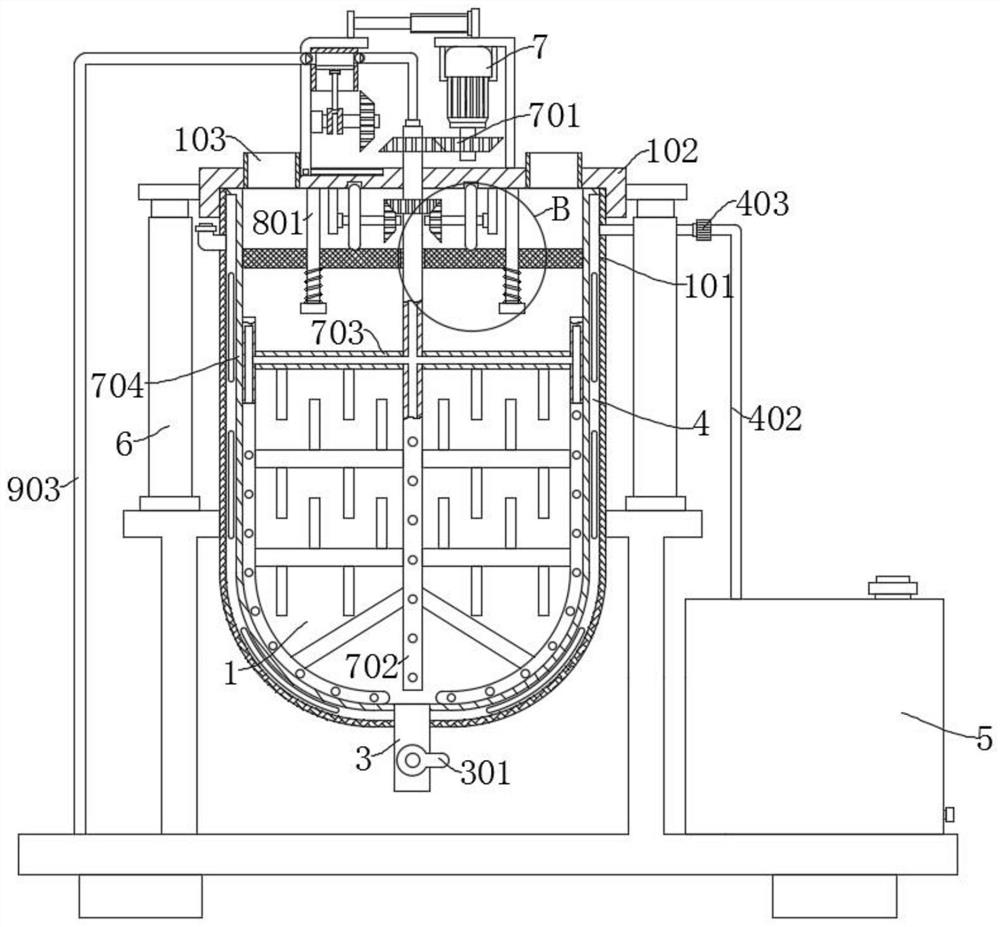

[0034] refer to Figure 1-5 , a paint mixing device for a water pump production line, including a support base 2, a mixing tank 1 is arranged on the support base 2, and a mixing assembly arranged in the mixing tank 1 for mixing the paint, and the top of the mixing tank 1 is provided with The tank cover 102, and the feed port 103 arranged on the tank cover 102; the scraper 704, arranged on the mixing assembly, and the scraper 704, and the mixing assembly are all provided with water nozzles 906; the water storage tank 5, arranged on the support seat 2, the mixing tank 1 and the water storage tank 5 are all provided with heating and heat preservation components, which are convenient for heating and heat preservation of the paint added to the mixing tank 1 and the water in the water storage tank 5 through the heating and heat preservation components; the piston assembly 903 is arranged on Above the tank cover 102; one end of the conduit 904 is connected to the water storage tank 5...

Embodiment 2

[0047] refer to figure 1 , figure 2 , a paint mixing device for a water pump production line, which is basically the same as in Example 1, furthermore, the outer wall of the mixing tank 1 is provided with an insulating layer 101; through the insulating layer 101, the loss of heat in the mixing tank 1 can be reduced, and Avoid burns when the staff touches the outer wall of the mixing tank 1 .

Embodiment 3

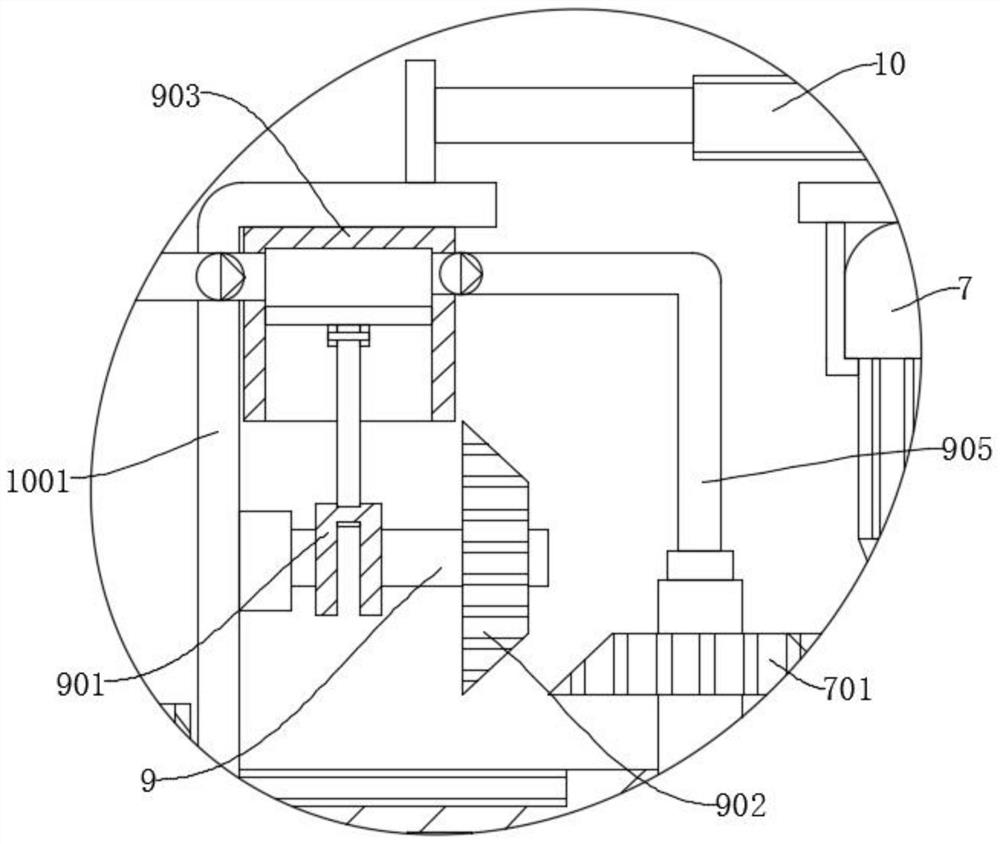

[0049] refer to Figure 1-Figure 3 , a paint mixing device for a water pump production line, which is basically the same as that of Embodiment 1, and furthermore, the drive assembly that drives the piston assembly 903 to move to supply water to the water nozzle 906 includes an electric telescopic rod 10, and the electric telescopic rod 10 is installed on the On the tank cover 102, the output end of the electric telescopic rod 10 is provided with a support plate 1001, the piston assembly 903 is arranged on the support plate 1001, the support plate 1001 is equipped with a rotating shaft 3 9, and a crankshaft 901 and a bevel gear 902 are arranged on the rotating shaft 3 9, The crankshaft 901 is rotatably connected to the piston assembly 903 , and the bevel gear 902 is driven by the electric telescopic rod 10 to engage or separate from the first transmission group 701 .

[0050] After the paint is mixed and discharged out of the mixing tank 1 through the discharge pipe 3, the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com