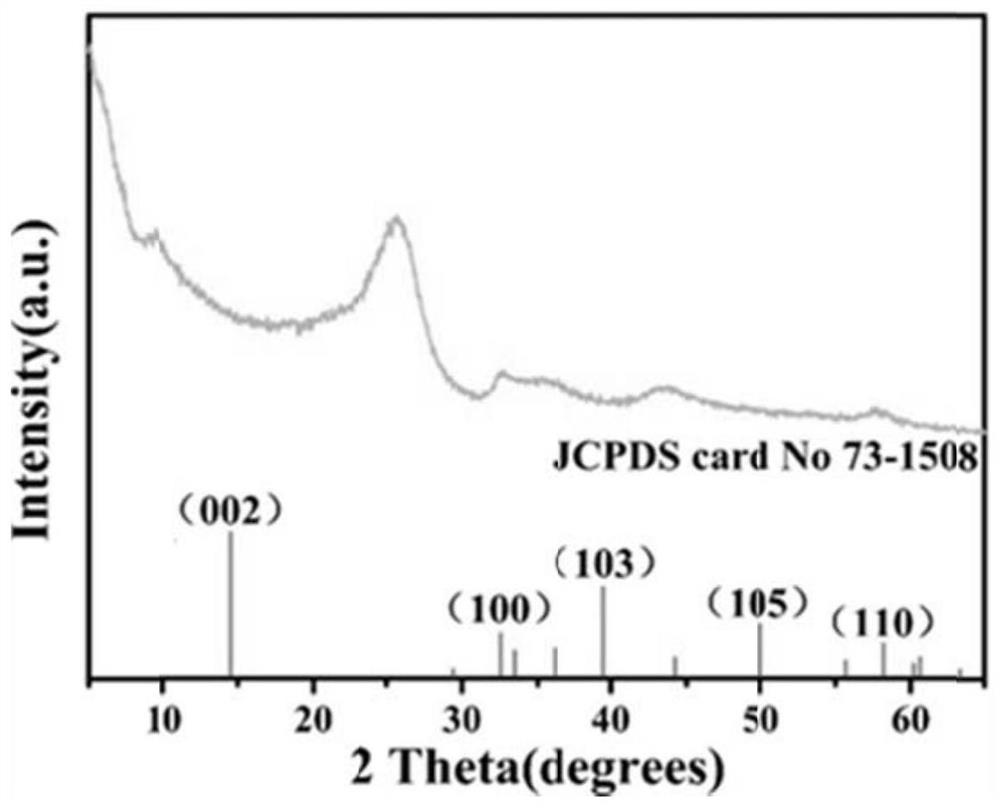

Preparation method of oxygen-doped molybdenum disulfide nanosheet hydrogen evolution electrocatalyst rich in defects

A molybdenum disulfide, electrocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of limited base electrocatalyst application ability, loss of electrical conductivity, hydrogen evolution performance gap, etc., to achieve high efficiency and stability The effect of hydrogen evolution performance, high repetition rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

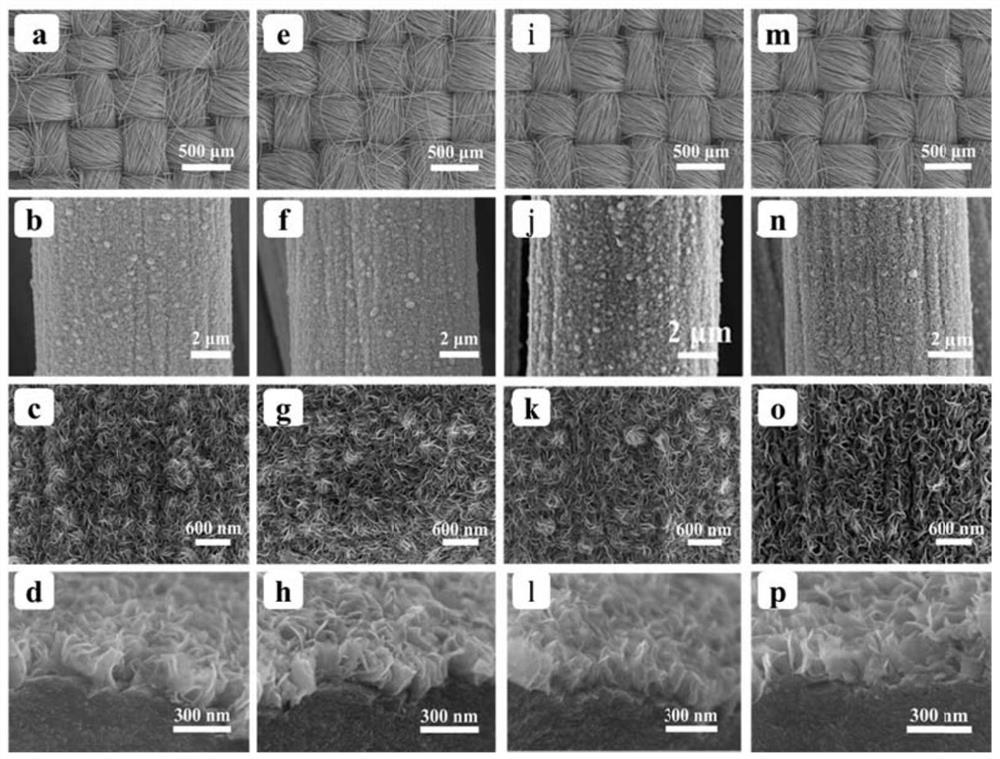

Embodiment 1

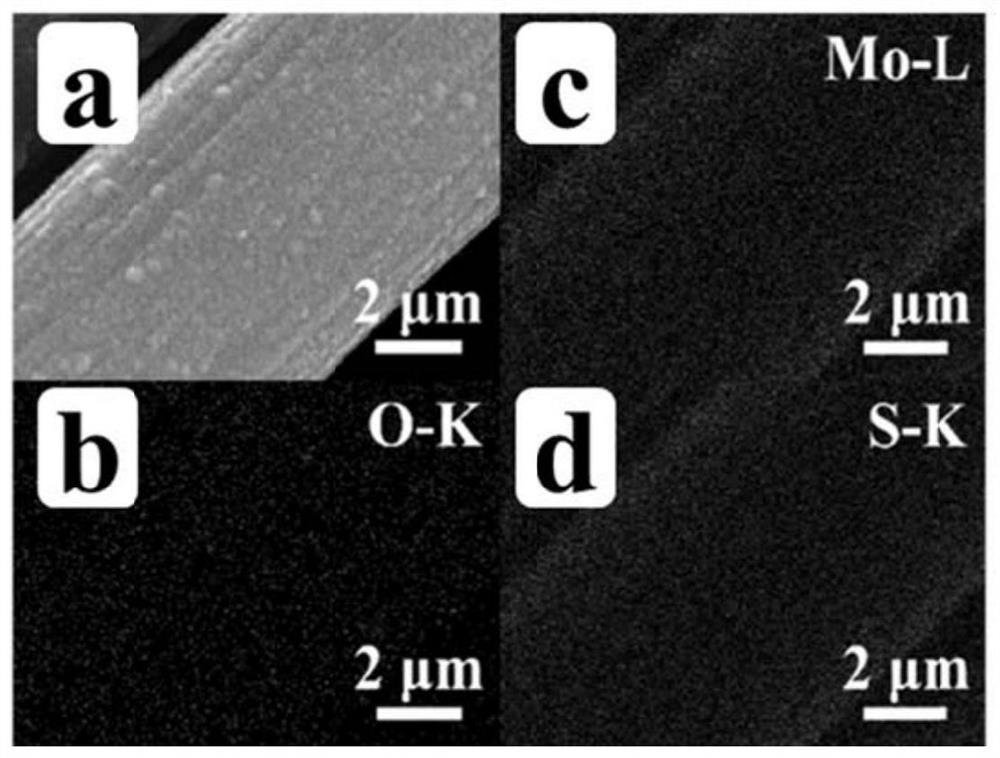

[0044] A defect-rich O-MoS 2 / CC preparation method of hydrogen evolution electrocatalyst. Its preparation method is as follows:

[0045] (1) Pretreatment of carbon cloth. First, soak the carbon arrangement in concentrated nitric acid for 30 minutes, then place it in water heating at 120°C for 30 minutes, and cool it to room temperature with the furnace, ready to use.

[0046] (2) Take out the carbon cloth treated in step (1), wash it with absolute ethanol and deionized water for 3 to 5 times, and then place it in an oven at 60°C to dry for later use.

[0047] (3) Take thiourea with an electronic balance, and dissolve it in 40 mL of deionized water with ammonium molybdate, control the (S / Mo) molar ratio of thiourea and ammonium molybdate to be 5.0, and the concentration of thiourea to be 0.04mol / L at room temperature Under magnetic stirring for 25min.

[0048] (4) Transfer the carbon cloth obtained in step (2) and the solution obtained in step (3) to a 50mL reaction kettle...

Embodiment 2

[0060] A defect-rich O-MoS 2 / CC preparation method of hydrogen evolution electrocatalyst. Its preparation method is as follows:

[0061] (1) Pretreatment of carbon cloth. First, soak the carbon arrangement in concentrated nitric acid for 30 minutes, then place it in water heating at 120°C for 30 minutes, and cool it to room temperature with the furnace, ready to use.

[0062] (2) Take out the carbon cloth treated in step (1), wash it with absolute ethanol and deionized water for 3 to 5 times, and then place it in an oven at 60°C to dry for later use.

[0063] (3) Take thiourea with an electronic balance, and dissolve it in 40 mL of deionized water with ammonium molybdate, control the (S / Mo) molar ratio of thiourea and ammonium molybdate to be 5.0, and the concentration of thiourea to be 0.04mol / L at room temperature Under magnetic stirring for 25min.

[0064] (4) Transfer the carbon cloth obtained in step (2) and the solution obtained in step (3) to a 50mL reaction kettle...

Embodiment 3

[0071] A defect-rich O-MoS 2 / CC preparation method of hydrogen evolution electrocatalyst. Its preparation method is as follows:

[0072] (1) Pretreatment of carbon cloth. First, soak the carbon arrangement in concentrated nitric acid for 50 minutes, then place it in water heating at 120°C for 30 minutes, and cool it to room temperature with the furnace, ready to use.

[0073] (2) Take out the carbon cloth treated in step (1), wash it with absolute ethanol and deionized water for 3 to 5 times, and then place it in an oven at 60°C to dry for later use.

[0074] (3) Take thiourea with an electronic balance, and dissolve it in 40 mL of deionized water with ammonium molybdate, control the (S / Mo) molar ratio of thiourea and ammonium molybdate to be 3.0, and the concentration of thiourea is 0.04mol / L at room temperature Under magnetic stirring for 25min.

[0075] (4) Transfer the carbon cloth obtained in step (2) and the solution obtained in step (3) to a 50mL reaction kettle. U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com