Nitrogen-doped carbon-coated Ni&MoO2 ultrafine nanowire and preparation method and application thereof

A nitrogen-doped carbon and ultra-fine nanotechnology, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as limiting the catalytic activity of hydrogen evolution reaction, less active sites, and agglomeration. Achieve excellent hydrogen evolution reaction catalytic activity and durability, improve catalytic activity, and improve acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

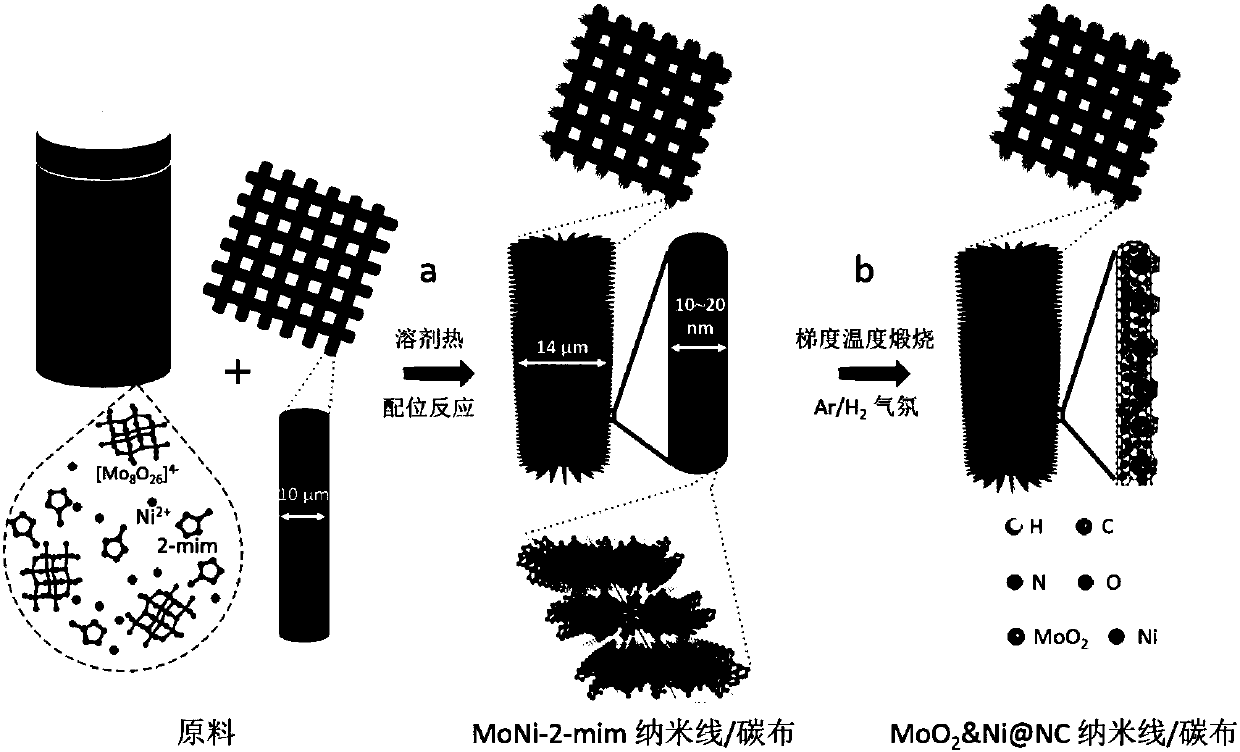

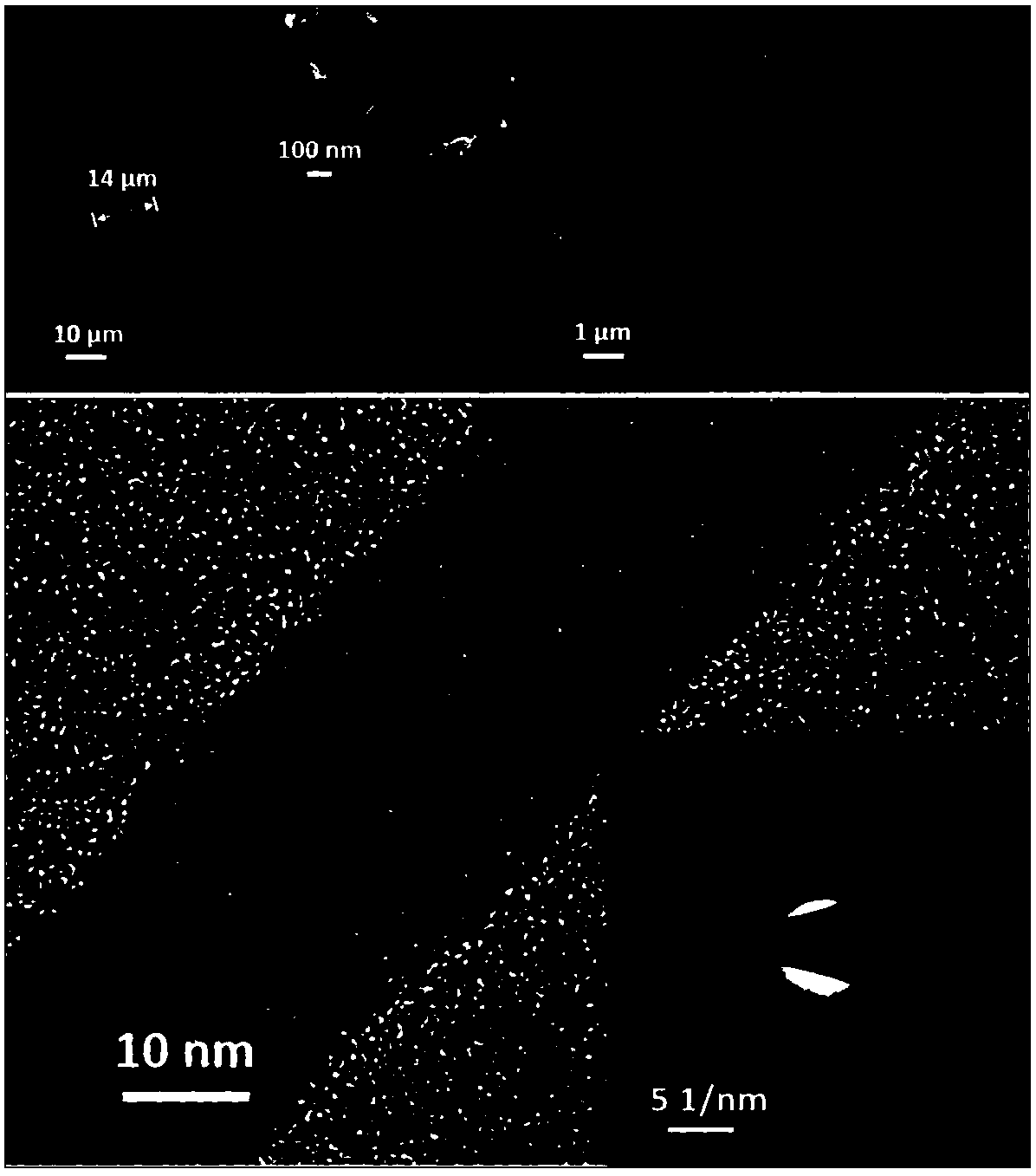

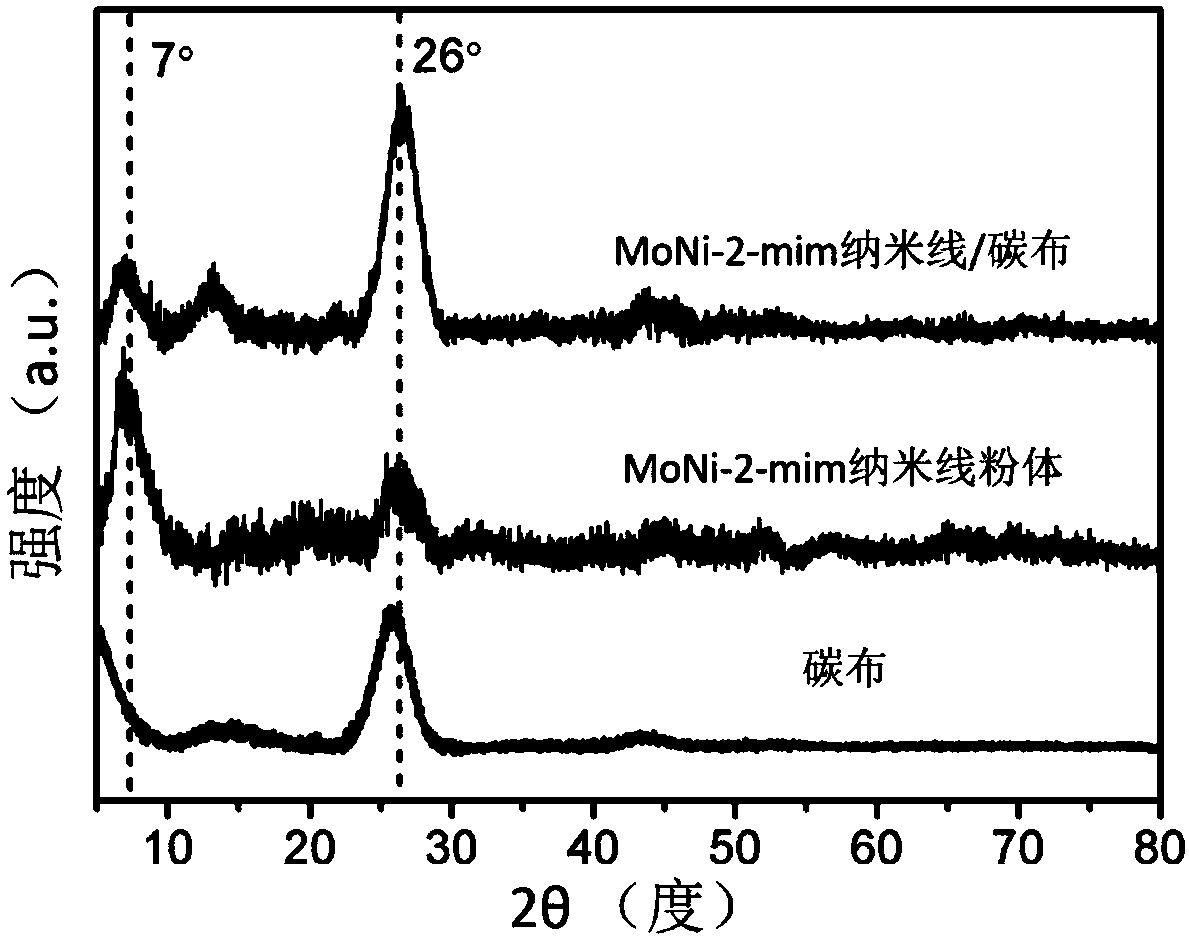

[0037] Nitrogen-doped carbon-coated Ni and MoO grown on carbon cloth 2 A method for preparing a composite nanowire material of nanoparticles, comprising the steps of:

[0038] 1) First, take 0.3g of ammonium molybdate tetrahydrate, 0.2g of nickel nitrate hexahydrate and 0.5g of 2-methylimidazole, and sequentially add them to 40mL of methanol solvent, and stir to obtain a homogeneous solution;

[0039] 2) Transfer the solution obtained in step 1) to a 50mL reactor, and vertically place a 20.0mm×30.0mm carbon cloth in it, and conduct solvothermal reaction at 160°C for 24h;

[0040] 3) After cooling down to room temperature, take out the carbon cloth sample from the reaction kettle in step 2), wash it with deionized water and absolute ethanol three times respectively, and dry it in a vacuum oven at 70°C to obtain the carbon cloth sample grown on carbon cloth. On-cloth, nickel-containing polymolybdate organic-inorganic nanowire precursors;

[0041] 4) with step 3) the product obta...

Embodiment 2

[0046] 1) Take 0.3g of ammonium molybdate tetrahydrate, 0.2g of nickel nitrate hexahydrate and 0.5g of 2-methylimidazole, add them to 40mL of methanol solvent in sequence, and stir to obtain a homogeneous solution;

[0047] 2) Transfer the solution obtained in step 1) to a 50mL reactor, and vertically place a 20.0mm×30.0mm carbon cloth in it, and conduct a solvothermal reaction at 180°C for 24h;

[0048] 3) After cooling down to room temperature, take out the carbon cloth sample from the reaction kettle in step 2), wash it with deionized water and absolute ethanol three times respectively, and dry it in a vacuum oven at 70°C to obtain the carbon cloth sample grown on carbon cloth. On-cloth, nickel-containing polymolybdate organic-inorganic nanowire precursors;

[0049] 4) with step 3) the product obtained in Ar / H 2 Gradient temperature calcination is carried out under the atmosphere, the calcination temperature of the first step is 280°C, the calcination time is 2h, and the h...

Embodiment 3

[0052] 1) Take 0.3g of ammonium molybdate tetrahydrate, 0.2g of nickel nitrate hexahydrate and 0.5g of 2-methylimidazole, add them to 40mL of methanol solvent in sequence, and stir to obtain a homogeneous solution;

[0053] 2) Transfer the solution obtained in step 1) to a 50mL reactor, and vertically place a 20.0mm×30.0mm carbon cloth in it, and conduct a solvothermal reaction at 160°C for 20h;

[0054] 3) After cooling down to room temperature, take out the carbon cloth sample from the reaction kettle in step 2), wash it with deionized water and absolute ethanol three times respectively, and dry it in a vacuum oven at 70°C to obtain the carbon cloth sample grown on carbon cloth. On-cloth, nickel-containing polymolybdate organic-inorganic nanowire precursors;

[0055] 4) with step 3) the product obtained in Ar / H 2 Gradient temperature calcination is carried out under the atmosphere, the calcination temperature of the first step is 280°C, the calcination time is 2h, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com