Gypsum strip recovery processing device for orthopedics department

A technology of recycling and gypsum, applied in grain processing, transportation and packaging, stone processing equipment, etc., can solve problems such as unsafe operation, inconvenience, incomplete crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

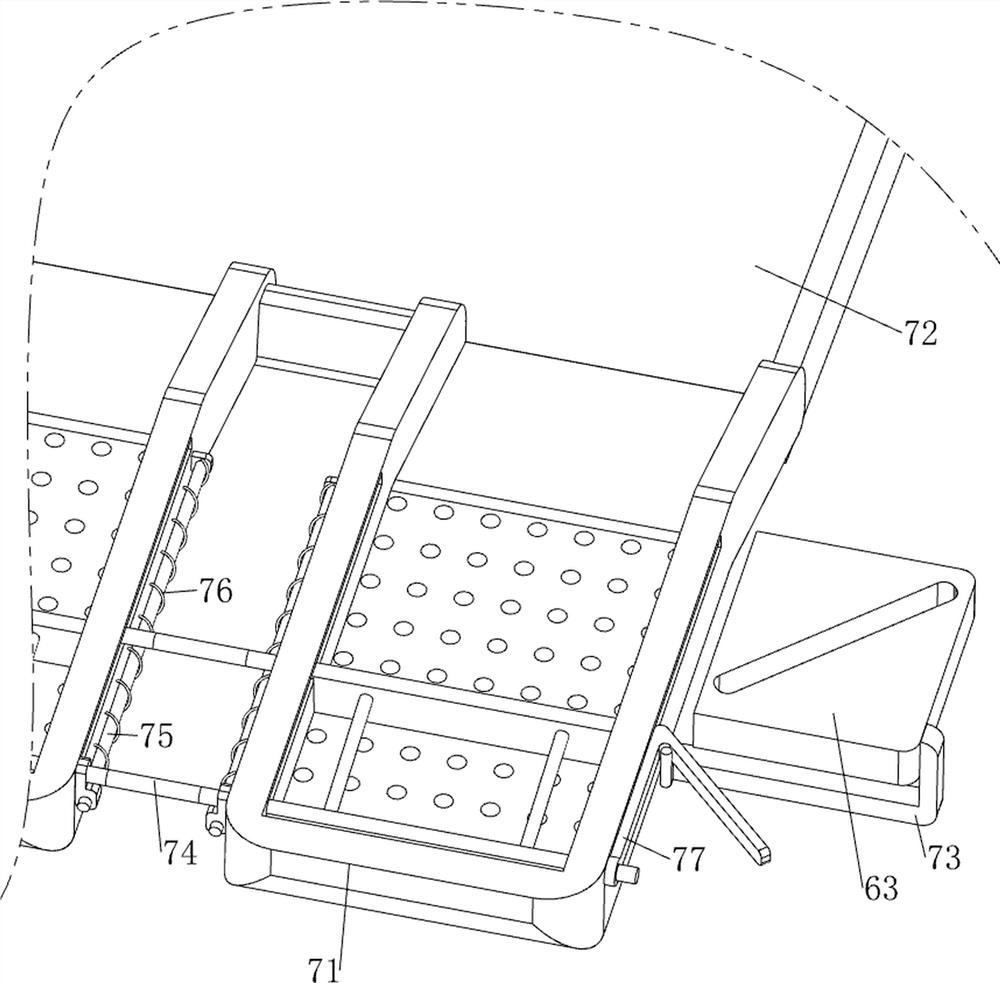

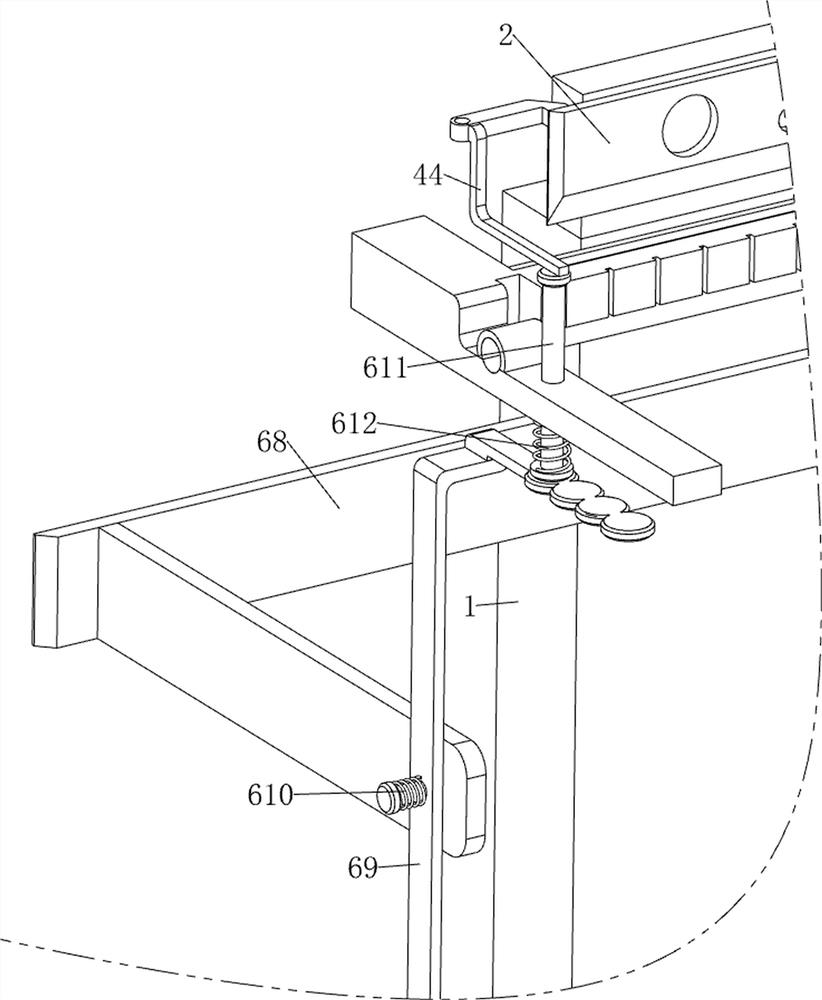

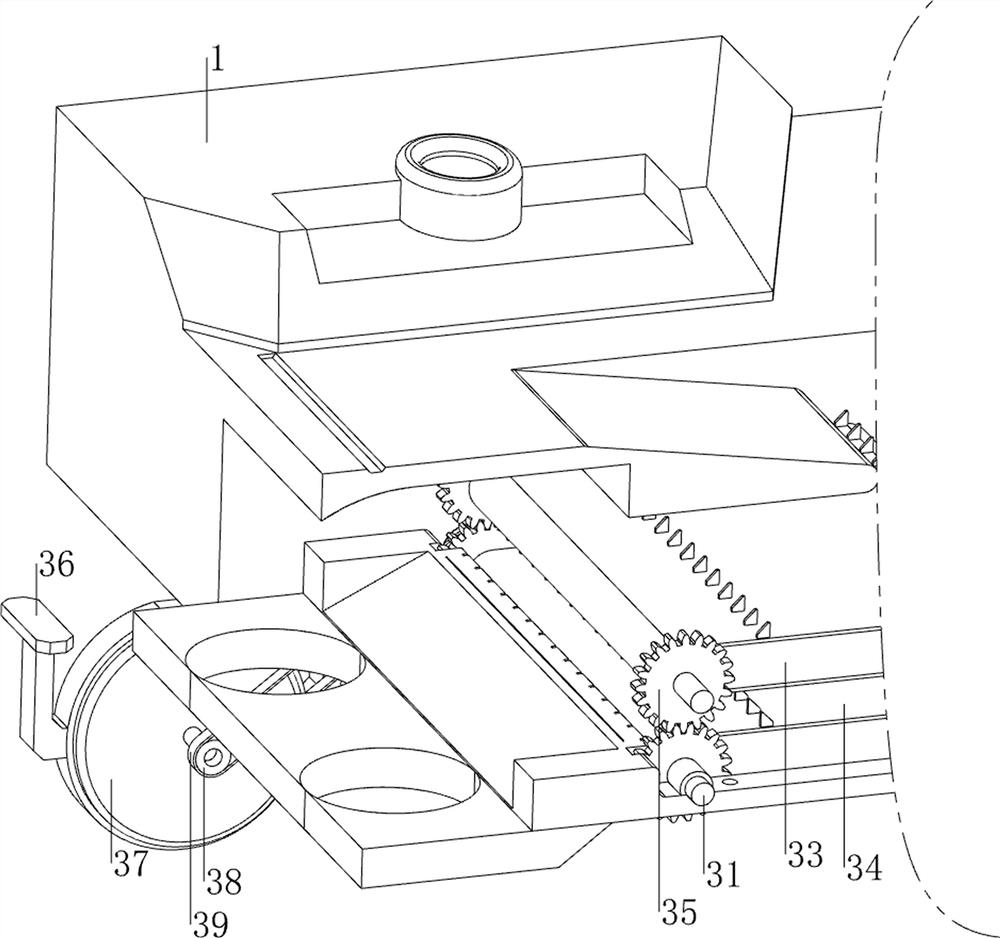

[0037] like Figure 1-15The shown a kind of orthopedic gypsum strip recovery processing device includes a shell 1, a blade 2, a transmission mechanism 3, a first rotating shaft 31, a roller 32, a first transmission belt 33, a second transmission belt 34, a spur gear 35, a first One fixed sleeve 36, servo motor 37, first flat belt 39, first pulley 38, segment mechanism 4, bump 41, fixed rod 42, first spring 43, slide block 44, crushing mechanism 5, second fixed sleeve 51, crushing cylinder 52, second rotating shaft 53, second pulley 54, second flat belt 55, third rotating shaft 56, bevel gear set 57, crushing sheet 58, helical blade 59, swing mechanism 6, guide groove 61, first Fixed block 62, first baffle plate 63, first guide rod 64, second spring 65, third spring 66, first slide bar 67, second fixed block 68, rotary block 69, torsion spring 610, pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com