Preparation method of atomizing core and atomizer

An atomizing core and equipment technology, which is used in the preparation of atomizing cores and in the field of atomizers, can solve the problems of poor size consistency, difficult installation, and slag drop of atomizing cores, and achieve high dimensional consistency, avoid breakage, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

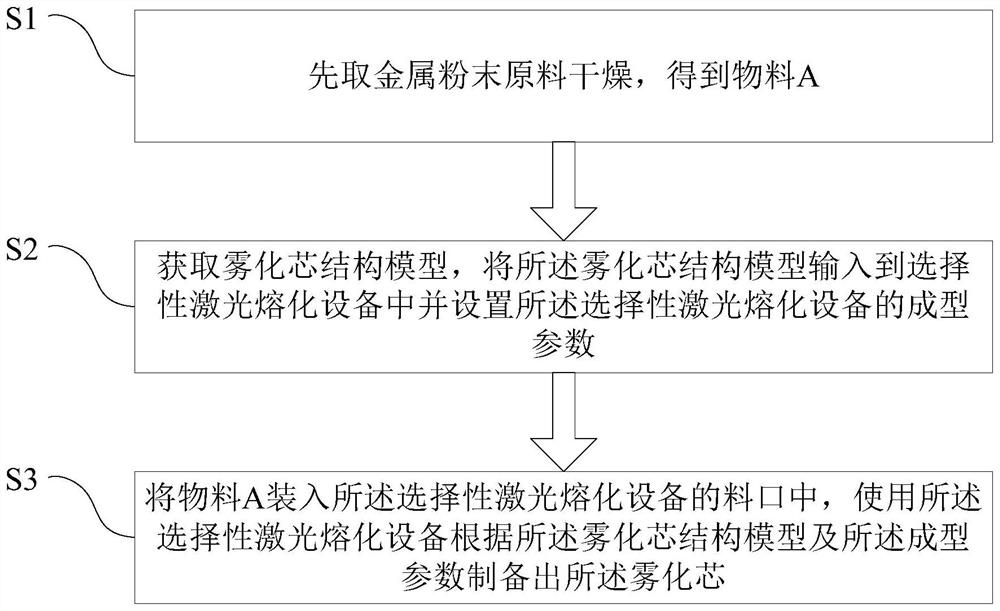

[0033] Such as figure 1 As shown, a method for preparing an atomizing core in this embodiment includes:

[0034] Step S1: First take the metal powder raw material and dry it to obtain material A;

[0035] Step S2: Obtain the structure model of the atomization core, input the structure model of the atomization core into the selective laser melting equipment and set the forming parameters of the selective laser melting equipment;

[0036] Step S3: Load material A into the material port of the selective laser melting equipment, and use the selective laser melting equipment to prepare the atomization core according to the structure model of the atomization core and the forming parameters.

[0037] The selective laser melting equipment is a kind of equipment that utilizes the thermal action of laser beams to rapidly melt and rapidly solidify metal powder.

[0038] Compared with related technologies, this application uses the metal powder to produce the atomization core through th...

Embodiment 2

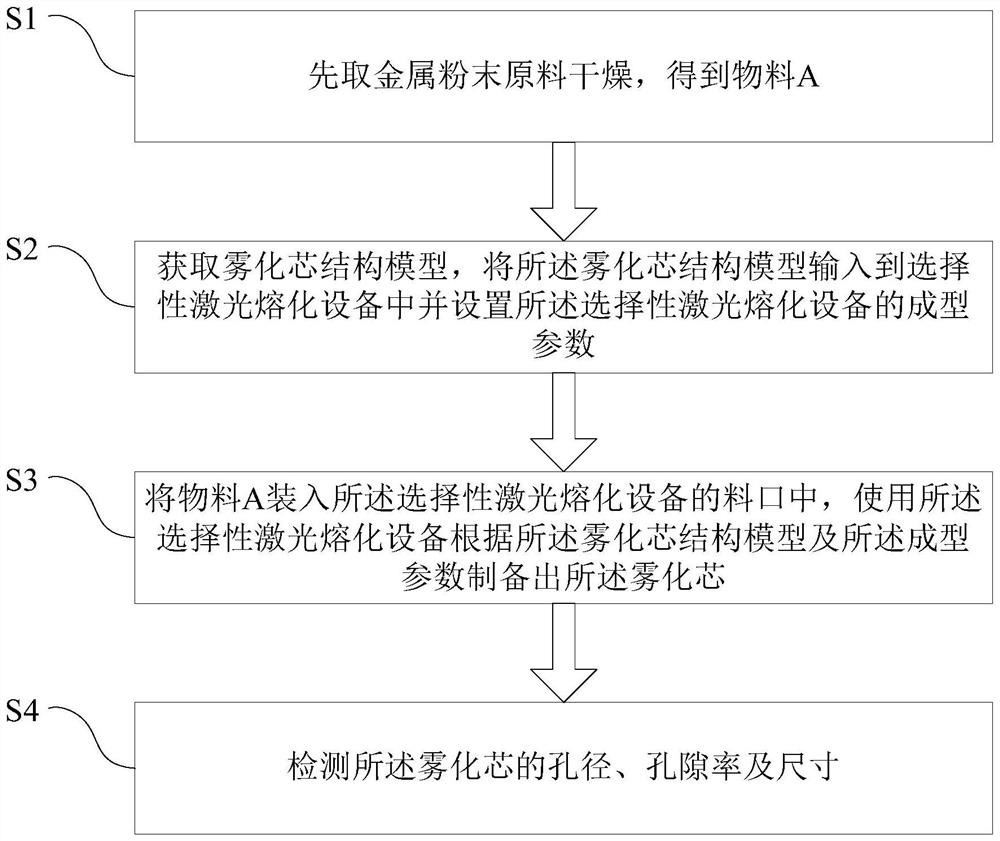

[0055] Such as figure 2 As shown, a preparation method of an atomizing core in this embodiment includes:

[0056] Step S1: First take the metal powder raw material and dry it to obtain material A;

[0057] Step S2: Obtain the structure model of the atomization core, input the structure model of the atomization core into the selective laser melting equipment and set the forming parameters of the selective laser melting equipment;

[0058] Step S3: loading material A into the material port of the selective laser melting equipment, and using the selective laser melting equipment to prepare the atomization core according to the structure model of the atomization core and the forming parameters;

[0059] Step S4: Detecting the pore diameter, porosity and size of the atomizing core, so as to reject unqualified products.

[0060] In one embodiment, the pore diameter of the atomizing core is less than or equal to 60um, the porosity of the atomizing core is greater than or equal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com