Novel closed belt conveyor

A belt conveyor, a new type of technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of waste of precious raw materials, small maintenance, falling on the workshop floor, etc., and achieve the effect of less material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

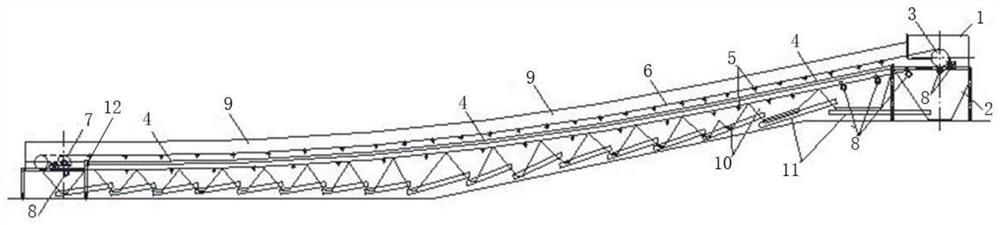

[0032] In further embodiments of the present invention, please continue to refer to figure 1 As shown, the belt conveyor 12 includes: an intermediate frame 4, the intermediate frame 4 is located between the head and the tail of the belt conveyor 12, and the intermediate frame 4 is provided with some idlers 5 and adhesive tapes 6, and the adhesive tape 6 is connected with the The head wheel 3 and the tail wheel 7 are connected by transmission, and several supporting rollers 5 are used to support the belt 6, and the belt 6 is used to transport bulk powder and block materials.

[0033] Preferably, the middle frame 4 is at the middle position of the belt conveyor.

[0034] In a further embodiment of the present invention, the belt conveyor 12 is provided with a tensioning device (not shown in the figure) at the tail wheel. Preferably, the tensioning device is a screw tensioner, a car tensioner and the like.

[0035] In a further embodiment of the present invention, at least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com