Graphene production device and method

A graphene and induction furnace technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of high price, high cost, loss of electrical properties of graphene, etc., and achieve the effect of easy collection and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

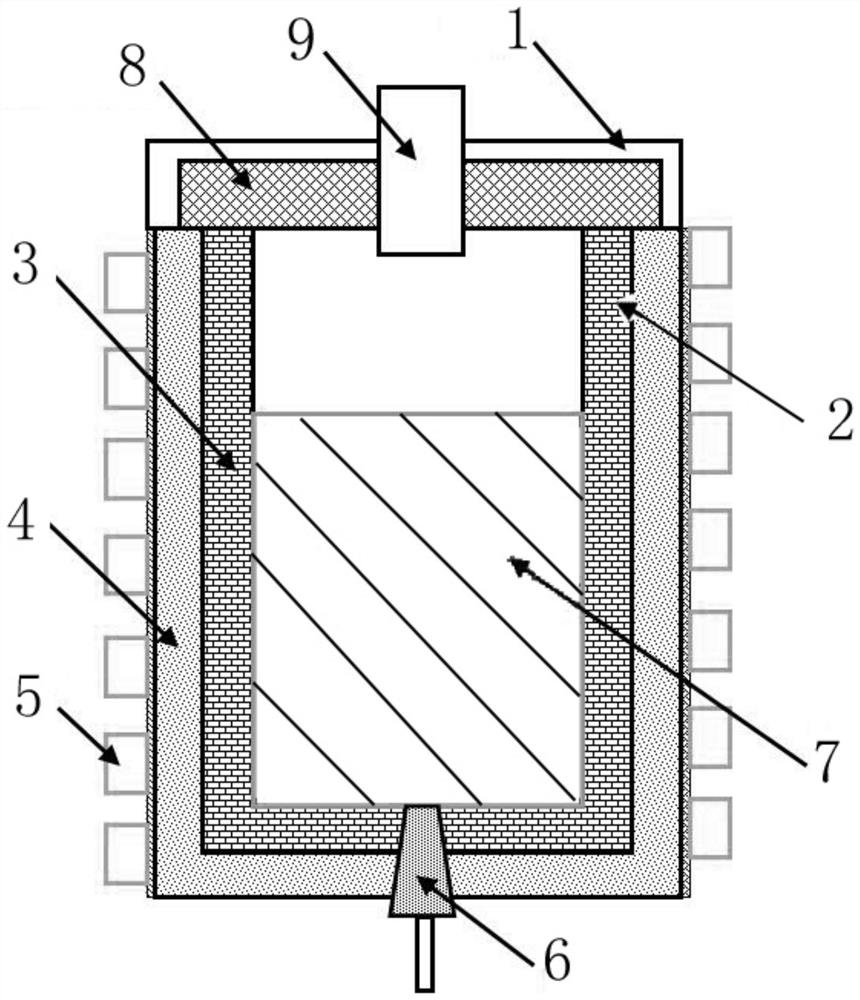

[0043] Such as figure 1 As shown, the device for producing graphene includes a furnace cover 1 and an induction furnace 2. The induction furnace 2 includes a furnace body 4 and an induction coil copper tube 5. The furnace body 4 is made of furnace lining ramming material, and the outside is surrounded by Induction coil copper pipe 5, the bottom of the furnace body 2 is provided with air-permeable bricks 6; the furnace cover 1 is provided with a collection pipe 9.

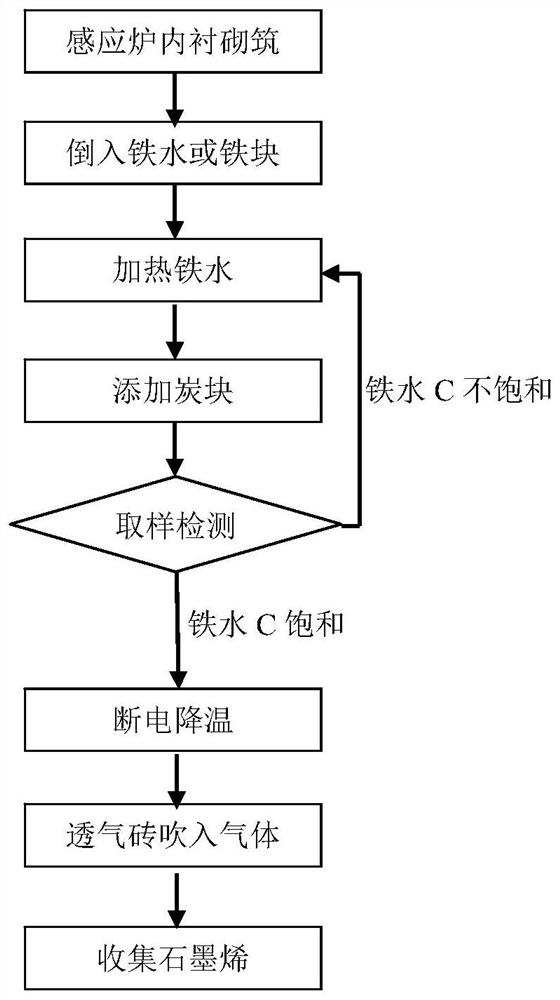

[0044] Taking the induction furnace 2 as a reactor, a layer of carbon bricks 3 with a thickness of 20-100 mm is built inside the furnace body 4 of the induction furnace 2, and the carbon brick C content is ≥ 99%. After building a layer of carbon bricks 3 inside the furnace body 4, the furnace cover 1 is opened, and iron blocks or molten iron 7 are poured into the furnace body 4. The iron block or molten iron 7 is heated through the induction coil copper tube 5, and the carbon brick 3 is used as a C source. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com