Natural super-warm-keeping jacquard fabric

A technology of jacquard and fabrics, which is applied in the field of textile fabrics, can solve the problems such as easy to grow mites and bacteria, and achieve the effects of strong hygroscopicity, good natural antibacterial effect, and excellent hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

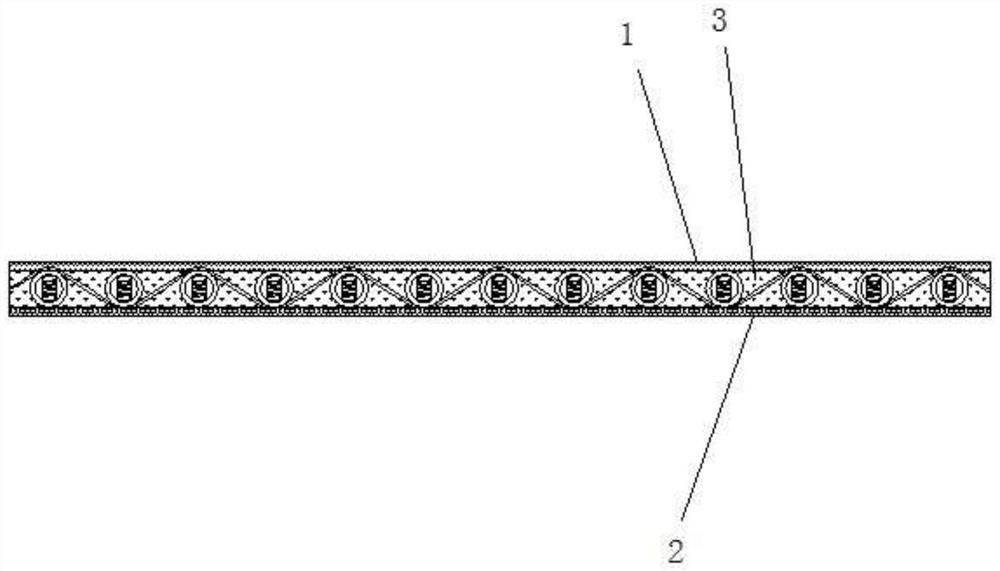

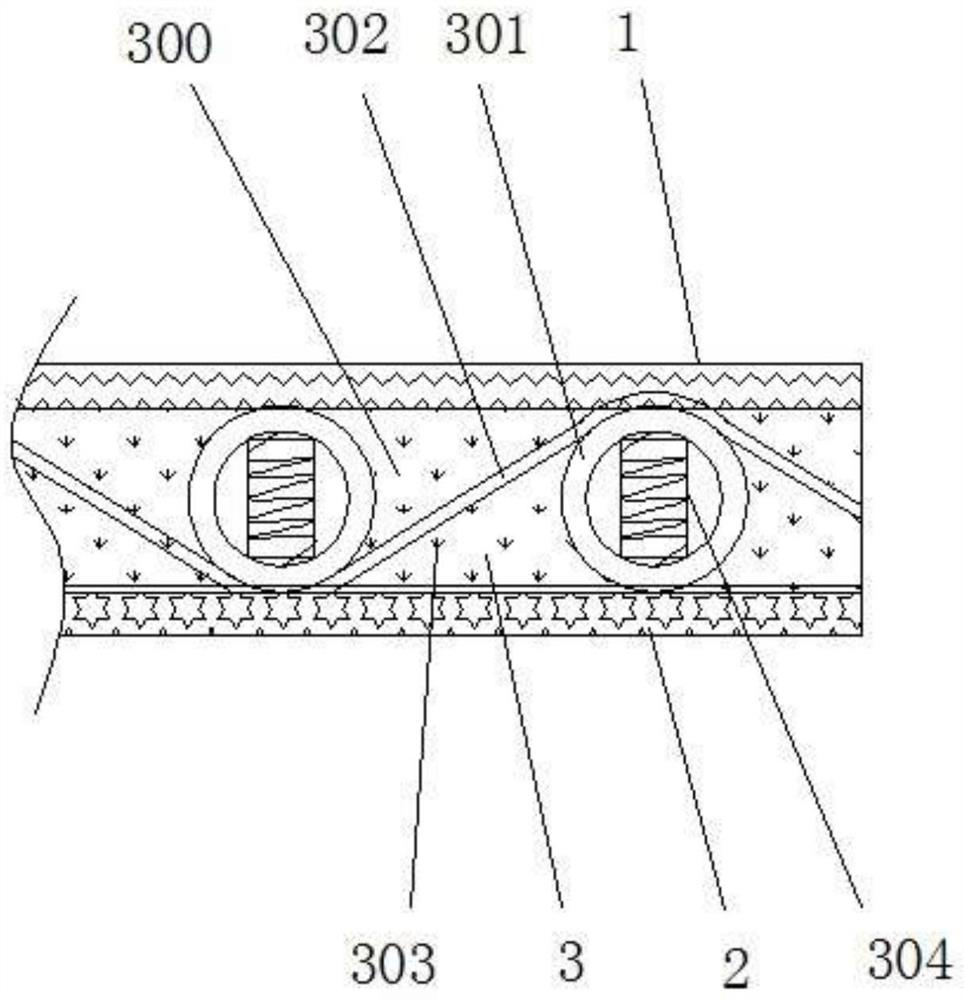

[0030] refer to Figure 1-2 , a natural super warm jacquard fabric is proposed in this embodiment, including.

[0031] Including the fabric body, and the weaving process of the whole fabric body is: warping → sizing → weaving → finishing → finished product → storage; the fabric body includes the first fabric layer 1 and the second fabric layer 2, and the first fabric There is also a sandwich layer 3 between the layer 1 and the second fabric layer 2;

[0032] The sandwich layer 3 includes a hollow space 300 disposed between the first fabric layer 1 and the second fabric layer 2, and a plurality of fabric loops 301 are arranged at equidistant intervals in the hollow space 300, and the fabric loops 301 are specifically composed of Hollow curved cotton fiber and wood fiber are fused together, and slender high-strength rubber bands are added to the fusion;

[0033] The raw materials of various components in the fabric circle 301 account for: 55-65% of cotton fiber, 30-35% of kapo...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is as follows:

[0047] In this example, elastic fiber threads 304 are also woven into the fabric loop 301, and the raw material components used in the elastic fiber threads 304 are: 94% kapok fiber and 6% elastic.

[0048] In this example, the raw materials of various components in the fabric loop 301 account for 63% of cotton fiber, 35% of kapok fiber, and 2% of elastic.

[0049] In this example, the raw materials used in the antibacterial thermal insulation filling 303 are: 43% cotton, 30% kapok, 20% plush fiber, 2% bamboo charcoal fiber, and 5% natural rain and hemp fiber.

[0050] In this example, the warp and weft are both composed of 55% viscose-based chitin fiber and 45% ultrafine modal fiber, and the warp and weft adopt satin weave and are woven into a jacquard fabric by a jacquard machine.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is as follows:

[0053] In this example, elastic fiber threads 304 are also woven into the fabric loop 301, and the raw material components used in the elastic fiber threads 304 are: 98% kapok fiber and 2% elastic.

[0054] In this example, the proportions of various raw materials in the fabric loop 301 are: cotton fiber 62%, kapok fiber 35%, and elastic 3%.

[0055] In this example, the raw materials used in the antibacterial thermal insulation filling 303 are: 41% cotton, 29% kapok, 25% plush fiber, 2% bamboo charcoal fiber, and 4% natural dew hemp fiber.

[0056] In this example, the warp and weft are both composed of 57% viscose-based chitin fiber and 43% ultrafine modal fiber, and the warp and weft adopt a satin weave and are woven into a jacquard fabric by a jacquard machine.

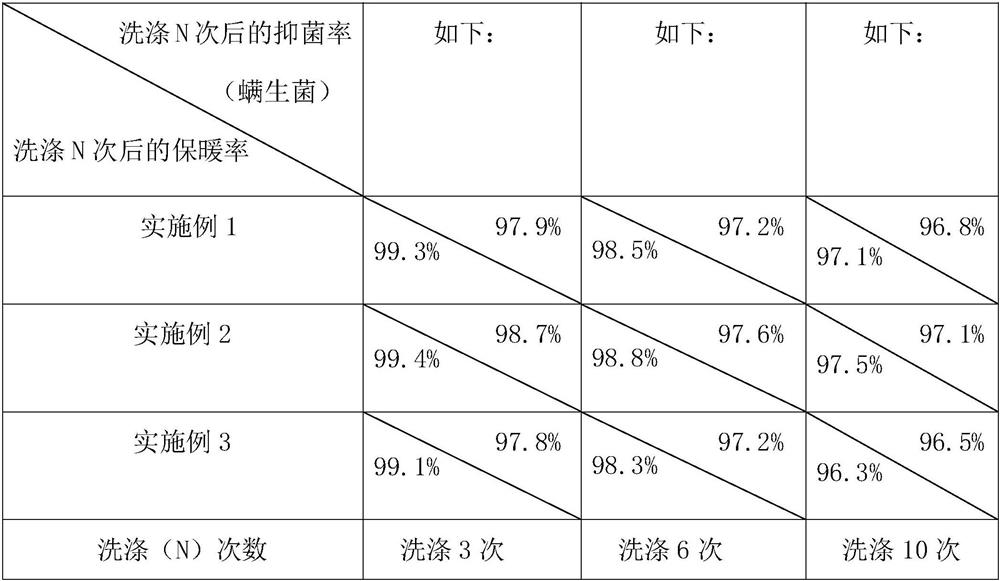

[0057] To the lining that embodiment 1 to embodiment 3 make, experimental data is as shown in the table below:

[0058]

[0059] As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com