Construction method of double-curved-surface dome metal roof

A technology of metal roofing and construction method, which is applied in the direction of roofing, roofing, roof covering layer using flat/curved panels, etc., can solve the problems that affect the quality of the project, the construction quality of space keel special-shaped panels is not easy to guarantee, and the single-layer hyperboloid dome metal roof Insufficient construction technology and other problems, to ensure the waterproof effect, reduce the risk of high-altitude operations, and reduce the effect of high-altitude welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

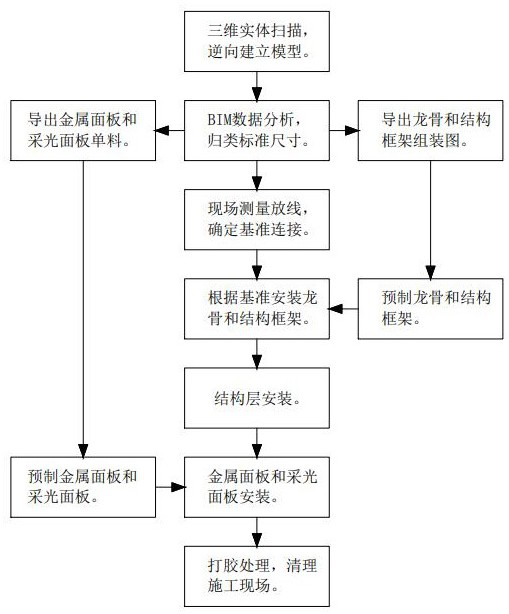

[0041] The embodiment of the present invention discloses a construction method of hyperbolic dome metal roof, referring to figure 1 , including the following construction steps:

[0042] Step 1: Carry out three-dimensional physical scanning of the metal roof structure layer, and reversely establish a model of the same size as the actual metal roof;

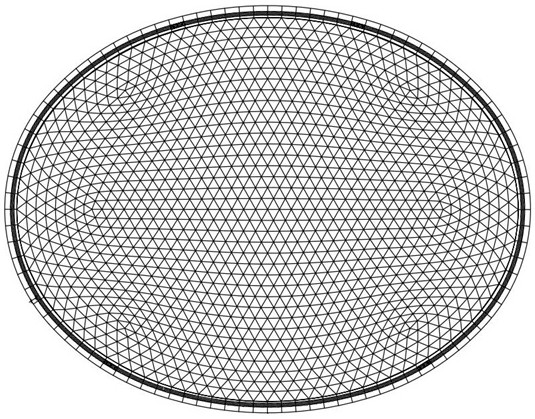

[0043] Step 2: Use BIM software to analyze and classify the mesh cells of the model scanned by the three-dimensional entity, classify the mesh cell size into standard size blocks, and count the number and size information of standard size blocks;

[0044] Step 3: On-site measurement and determination of reference points and connection points. The reference points are support points on the periphery of the building construction area. The determination of the reference points includes determination of the plane reference direction and determination of the vertical reference direction. The determination of the connection points Incl...

Embodiment 2

[0050] Increase on the basis of embodiment 1:

[0051] The model described in step 1 is obtained by first obtaining the spatial structure point cloud model, and then generating the solid structure model through software processing. After obtaining the model, the force situation of the specific construction structure is simulated by combining the model size information with the material information, and the structural collision is carried out at the same time. analyze.

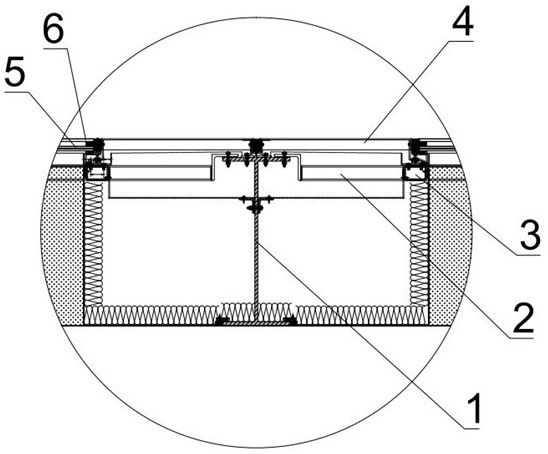

[0052] The structural frame 2 and the aluminum alloy support 4 are installed in the mesh unit described in step 2. After the size of the mesh unit is classified as a standard size block, the size of the components installed in the mesh unit is also classified as a standard size block.

[0053] The connection between the keel 1 and the structural frame 2 at the reference point and the connection point in step 3 is bolted connection, and the aluminum alloy support 4 and the metal panel 5 are connected by internal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com