Automatic drainage system for high-temperature and high-pressure steam pipeline

A steam pipeline, high temperature and high pressure technology, applied in steam traps, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of complex structure, short life, poor reliability, etc., to achieve accurate pressure parameters, long service life, The effect of convenient value selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

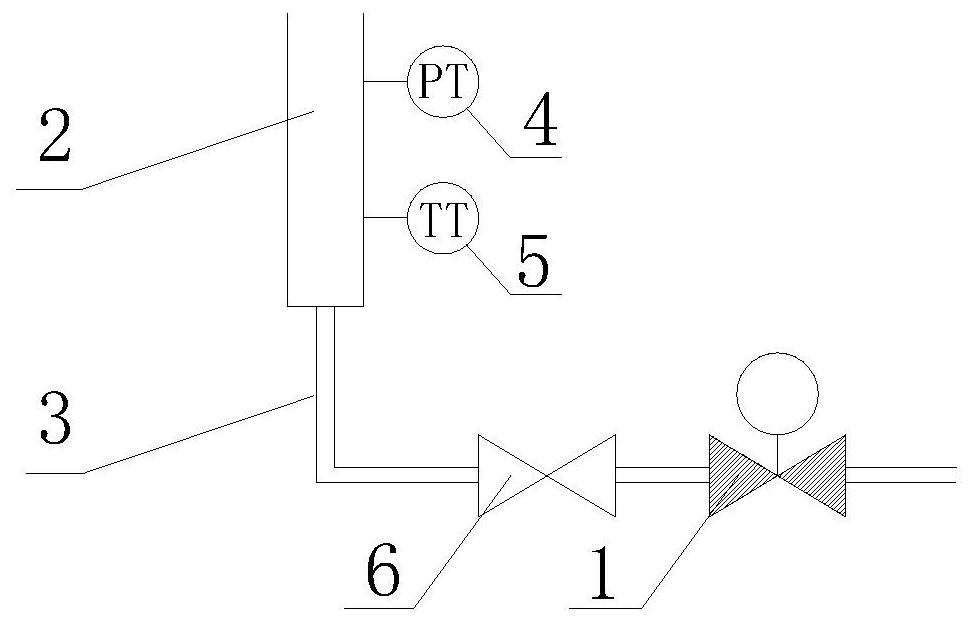

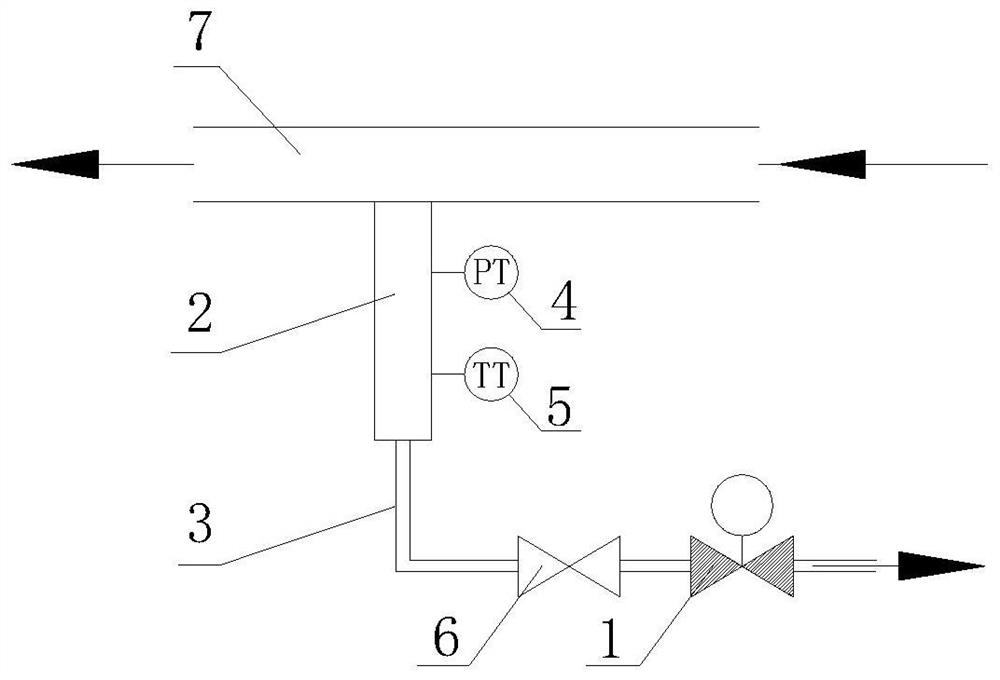

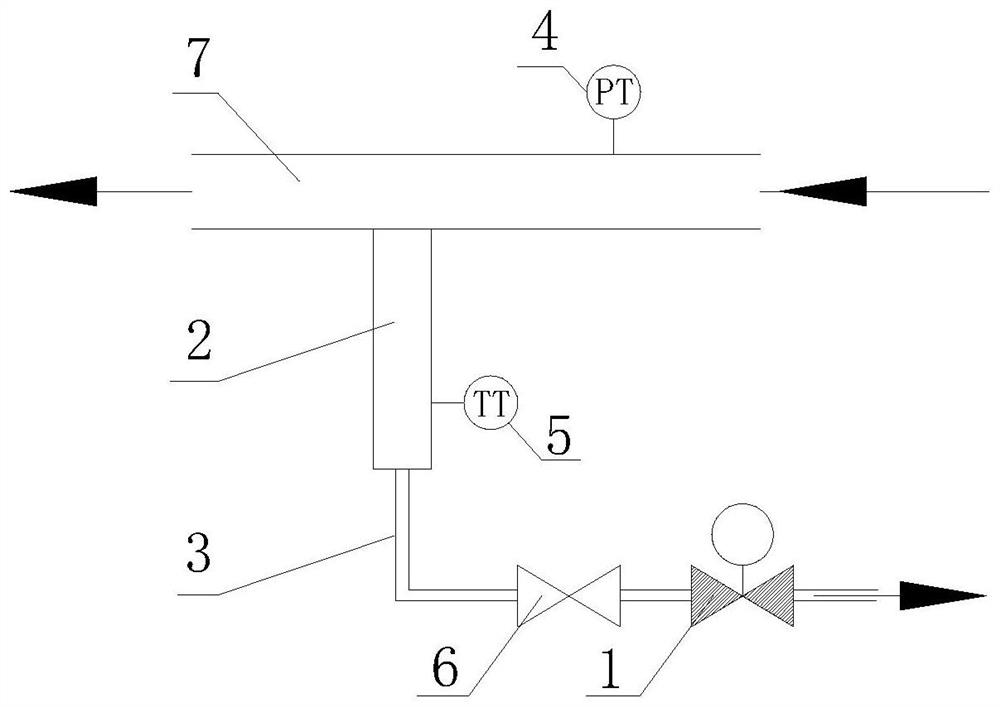

[0043] Such as figure 1 As shown, an automatic drainage device for high-temperature and high-pressure steam pipelines includes a drainage tank, a pressure sensor 4, a temperature sensor 5, an electric valve 1 and a control system; the electric valve 1 is arranged at the outlet of the drainage tank; the drainage tank includes a tank body 2. The temperature measuring element of the temperature sensor 5 is set on the tank body 2, the pressure measuring element of the pressure sensor 4 can be set on the tank body 2, and the setting height of the pressure sensor 4 pressure measuring element is higher than the setting height of the temperature sensor 5 temperature measuring element ; The temperature sensor 5 and the pressure sensor 4 are connected to the electrical signal of the control system, and the control system is connected to the electrical signal of the electric valve 1 .

[0044] The present invention collects the temperature in the hydrophobic tank through the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com