Sub-module temperature adjustment and balance method under centralized control based on modular multilevel converter

A modular multi-level, centralized control technology, applied in power transmission AC network, AC power input conversion to DC power output, electrical components and other directions, can solve the threat of safe and reliable operation of modular multi-level converters, increase hardware System and algorithm complexity, large temperature difference of sub-modules, etc., to achieve the effect of easy understanding and implementation, safe and reliable operation, and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

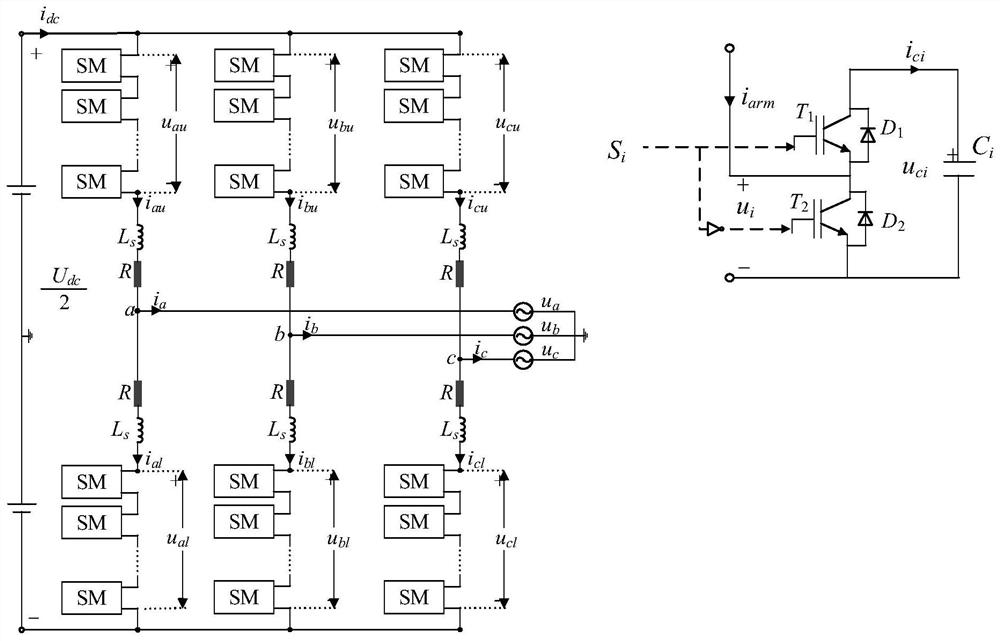

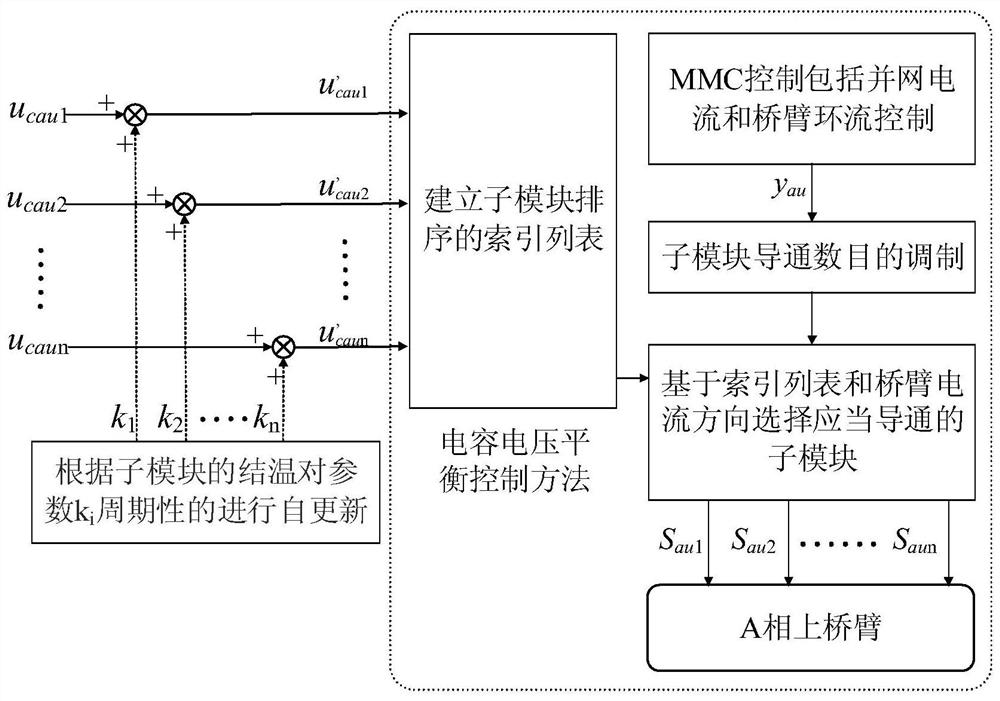

[0027] Aiming at the problem of uneven temperature distribution of the sub-module caused by thermal resistance aging of the sub-module power device, the present invention proposes a sub-module temperature adjustment and balance method suitable for MMC, wherein the MMC topology is composed of six bridge arms, such as figure 1 As shown, each bridge arm contains n identical submodules (Submodule, SM) and a bridge arm inductance L s , the sub-module adopts a half-bridge structure, and each sub-module consists of two power switches T 1 , T 2 , two diodes D 1 、D 2 Composed of a DC capacitor, the capacitor voltage balance method is: according to the comparison between the reference voltage of the bridge arm and the carrier, the number of sub-modules that need to be put into a bridge arm is n on , sort the virtual capacitor voltages obtained ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com