Device, method and system for testing performance parameters of thin-film thermoelectric material

A thermoelectric material and parameter testing technology, applied in the direction of material resistance, material thermal development, etc., can solve the problems of difficulty in meeting the actual needs of fast and simple testing of thin-film thermoelectric materials, low test accuracy, slow test speed, etc., to avoid damage or Uneven heat distribution, simplified test process, and improved test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

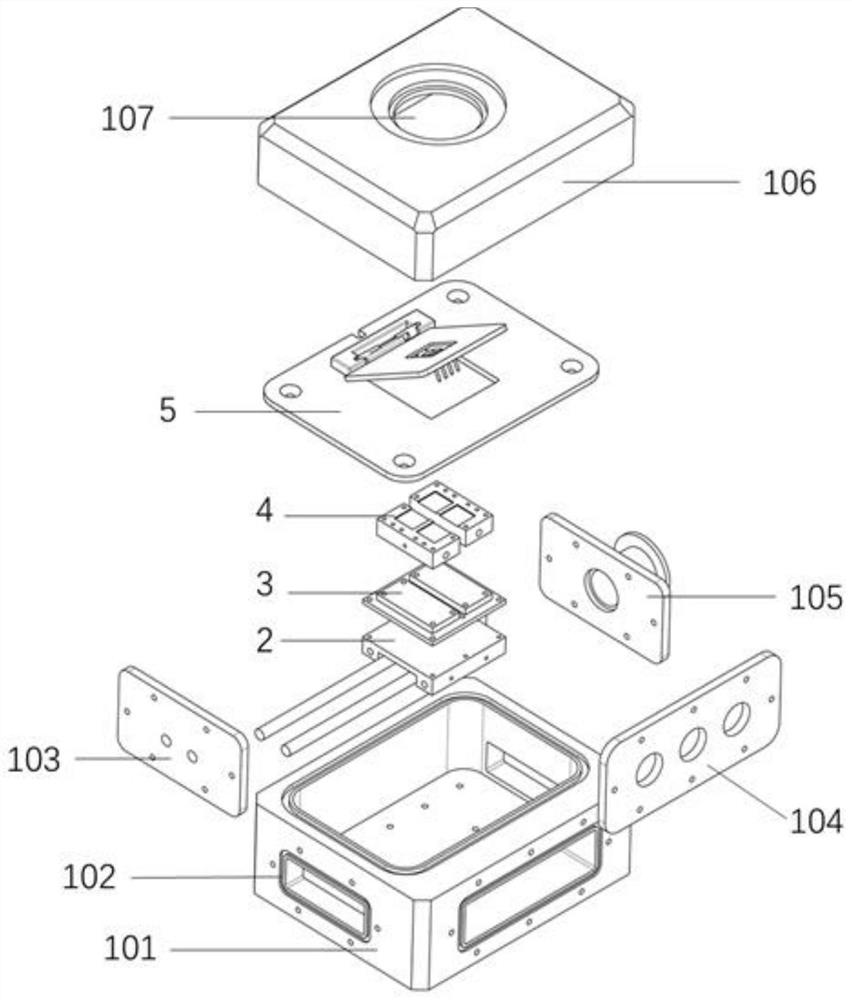

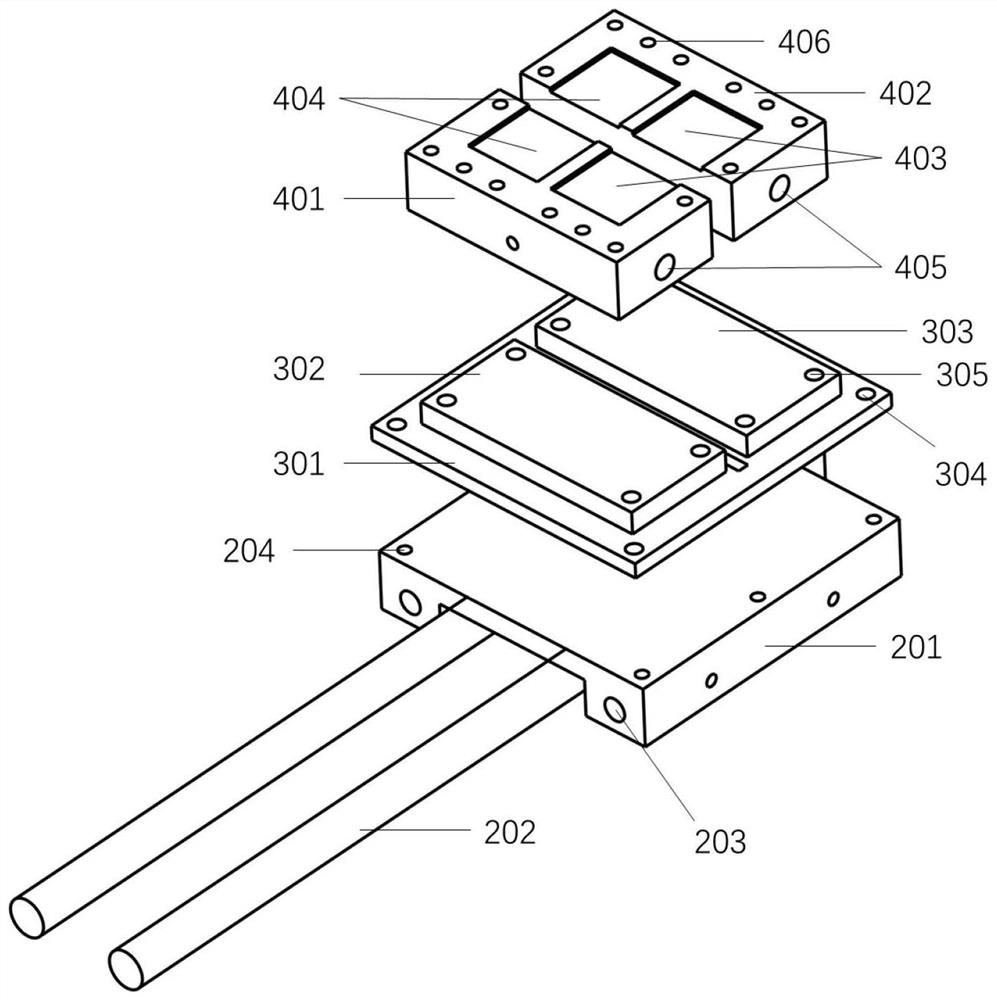

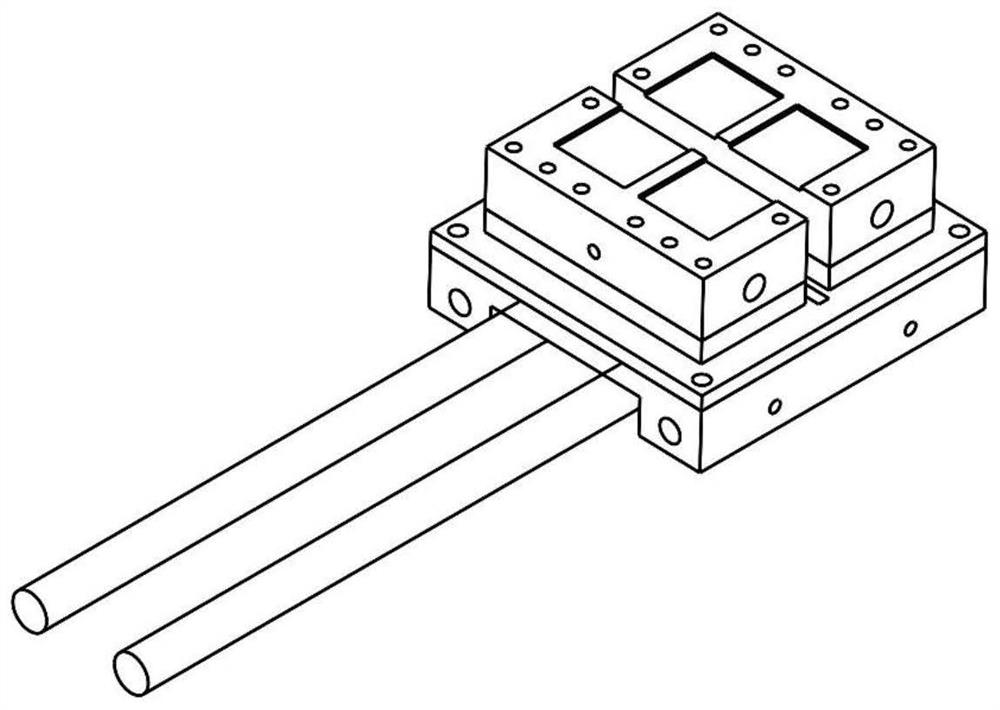

[0096] An embodiment of the present invention provides a device for testing thermoelectric performance parameters of thin film thermoelectric materials, such as figure 1 As shown, the device for testing thermoelectric performance parameters of thin film thermoelectric materials mainly includes: cavity (101-107), basic temperature control unit 2, buffer layer 3, temperature difference control unit 4, stylus fixing device 5 and testing equipment.

[0097] The basic temperature control unit 2 , the buffer layer 3 , and the sample temperature and temperature difference control unit 4 are relatively arranged inside the test chamber 101 .

[0098] The basic temperature control unit 2 is carried on the bottom of the test chamber 101 and is used to control the basic test temperature of the sample to be tested; after a single test, the basic temperature control unit 2 can be used to quickly return the sample to room temperature.

[0099] The buffer layer 3 is carried on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com