500 kilovolt power transmission line spacer electric fixture

A technology of transmission lines and spacers, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the complexity and labor intensity of maintenance operations, increasing the production cost of maintenance work, and narrow working space, so as to reduce the safety factor and work efficiency , Improve work efficiency and safety performance, easy and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

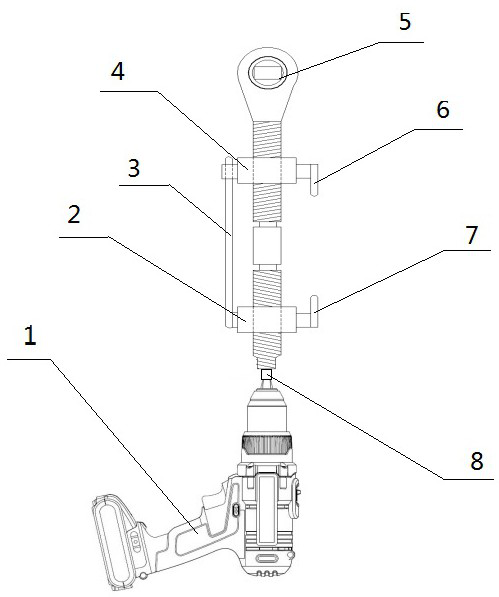

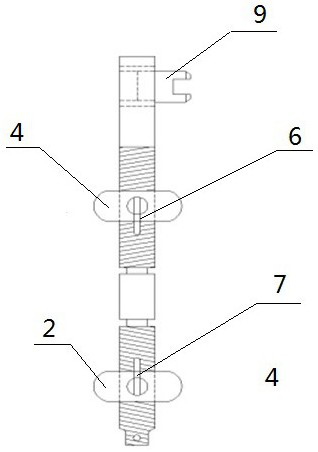

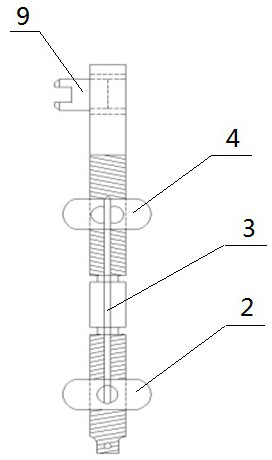

[0025] A 500 kV transmission line spacer electric fixture, which consists of: a spacer electric fixture, the spacer electric fixture includes a screw body, and the upper and lower sides of the screw body have threads respectively, wherein The lower thread is connected with the lower clamp of the spacer, the upper thread is connected with the upper clamp of the spacer, the left end of the lower clamp of the spacer and the upper clamp of the spacer are respectively connected with the upper and lower clamping positioning rods 3 of the spacer, A ratchet wrench 5 is installed on the top of the screw body, a screw wrench 8 is installed on the bottom of the screw body, and a ratchet clamp 9 is installed in the circular hole of the ratchet wrench. Connect with power tool 1.

Embodiment 2

[0027] In the 500 kV transmission line spacer electric fixture described in Example 1, an upper wrench 6 is installed at the right end of the upper clamp of the spacer, and a lower wrench 7 is installed at the right end of the lower clamp of the spacer. The upper and lower parts of the screw body are threads and the middle part is an optical axis structure.

[0028] This structure rationally integrates the functions of the ratchet spacer fixture and the lead screw spacer fixture. About 10kg, so this design effectively reduces the weight by 51%, making it easy for operators to carry during the actual maintenance work, effectively reducing physical energy consumption and work intensity during work, improving operating efficiency, and improving the safety of maintenance work;

[0029] The disassembly method of the 500 kV transmission line spacer electric jig uses a ratchet electric wrench and a spacer ratchet jig to loosen and tighten the spacer bolts, and the jig itself is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com