Novel essential oil aging accelerating and quality improving system and preparation process

An essential oil and aging technology, applied in the directions of essential oils/spice, fat production, etc., can solve problems such as poor preparation effect of aging devices, achieve better aging effect, simple structure, improve aging quality and aging The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

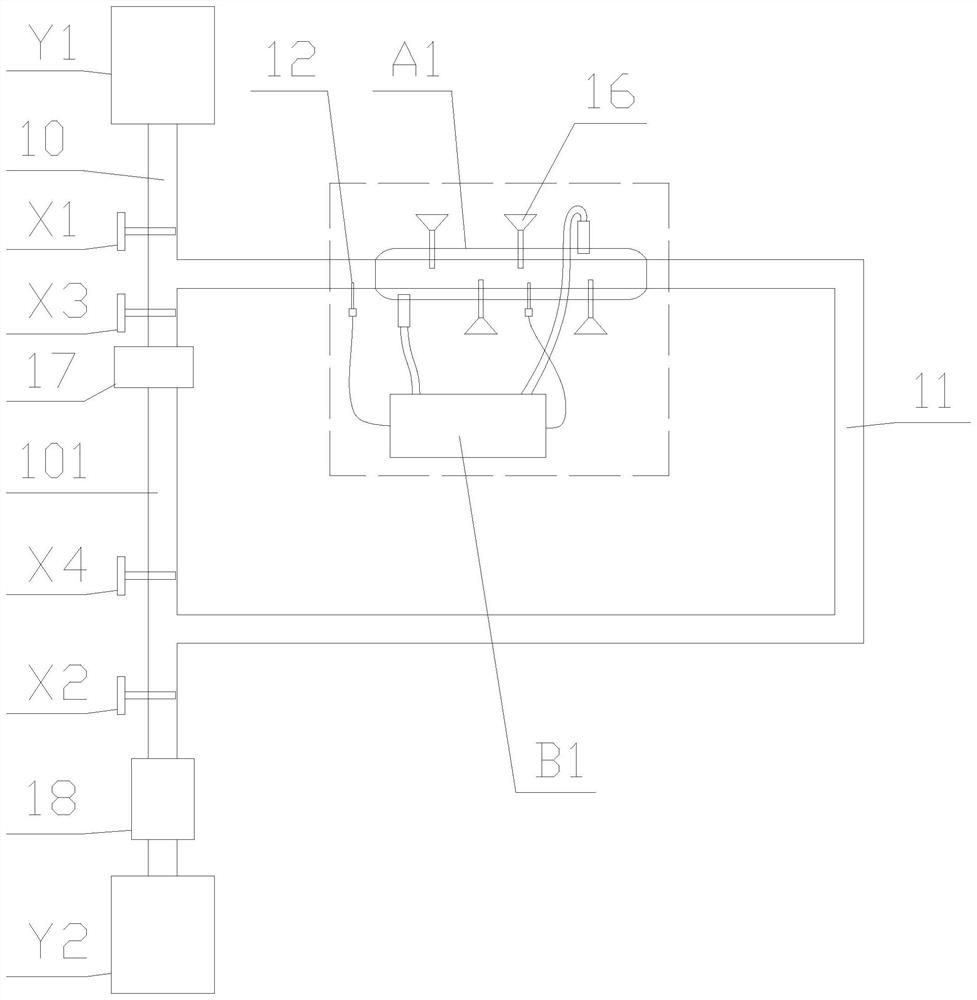

Embodiment 1

[0073] Please refer to figure 1 , Figure 5 As shown in the figure, a new type of system for enhancing aging of essential oil includes essential oil liquid storage tank Y1, essential oil liquid storage tank Y2, pipeline 10, temperature measurement and control-ultrasonic aging unit, essential oil liquid storage tank Y1 and essential oil The liquid storage tank Y2 is connected through the pipeline 10, the front part of the pipeline 10 is provided with a branch pipeline 11, and the other end of the branch pipeline 11 is connected to the rear part of the pipeline 10;

[0074] The temperature measurement and control-ultrasonic aging unit is arranged on the branch pipeline 11;

[0075] The temperature measurement and control-ultrasonic aging unit includes a temperature measuring sensor 12, a thermostat tube A1, a thermostat B1 and an ultrasonic aging device. The thermostat tube A1 is an inner and outer tube structure. A storage cavity C1 is formed between the outer tube and the in...

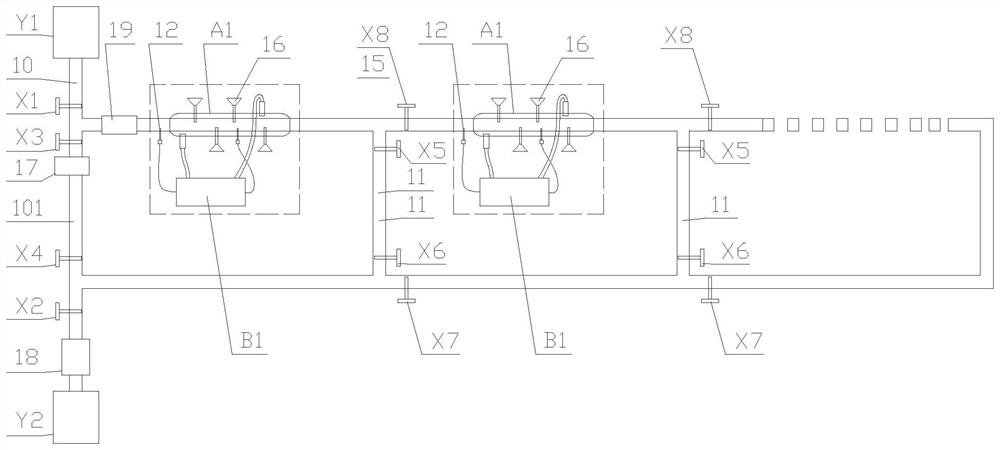

Embodiment 2

[0094] Please refer to figure 2 , Figure 5 As shown, a system for promoting the aging of essential oils includes an essential oil liquid storage tank Y1, an essential oil liquid storage tank Y2, a pipeline 10, a temperature measurement and control-ultrasonic aging aging unit, an essential oil liquid storage tank Y1 and an essential oil storage tank Y1. The liquid tank Y2 is connected through the pipeline 10, the front part of the pipeline 10 is provided with a branch pipeline 11, and the other end of the branch pipeline 11 is connected to the rear part of the pipeline 10;

[0095] The temperature measurement and control-ultrasonic aging unit is arranged on the branch pipeline 11;

[0096] The temperature measurement and control-ultrasonic aging unit includes a temperature measuring sensor 12, a thermostat tube A1, a thermostat B1 and an ultrasonic aging device. The thermostat tube A1 is an inner and outer tube structure. A storage cavity C1 is formed between the outer tube...

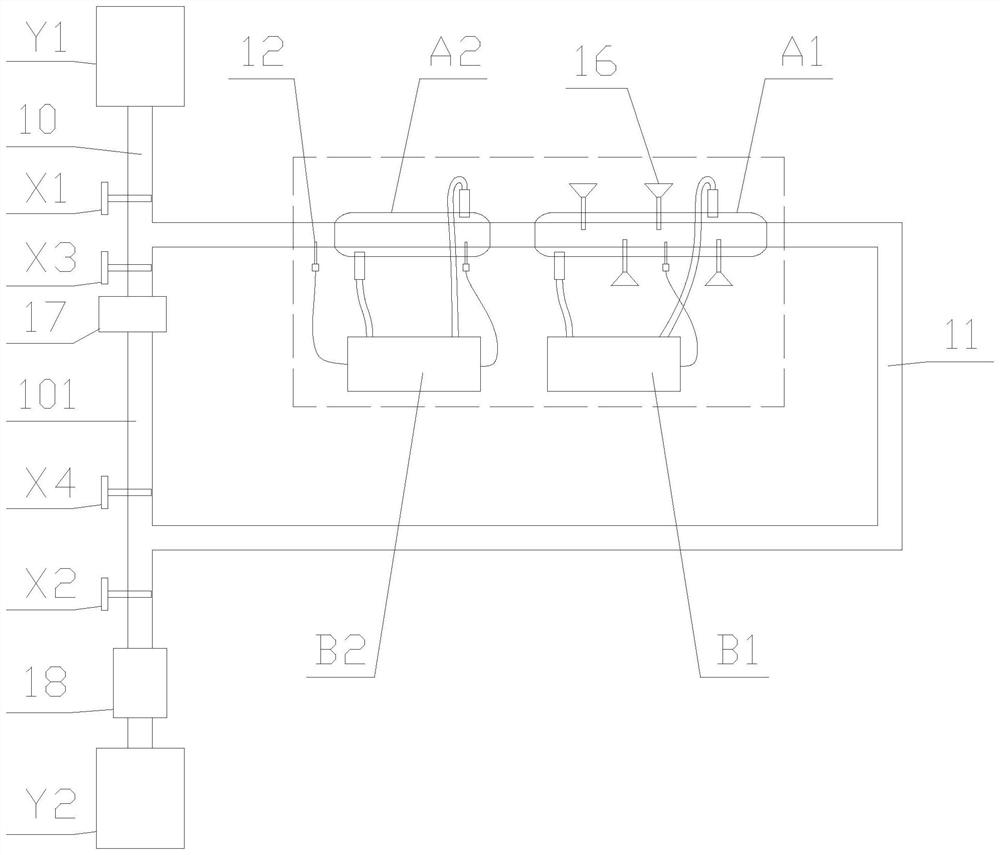

Embodiment 3

[0117] Please refer to image 3 , Figure 5 As shown in the figure, a new type of system for enhancing aging of essential oil includes essential oil liquid storage tank Y1, essential oil liquid storage tank Y2, pipeline 10, temperature measurement and control-ultrasonic aging unit, essential oil liquid storage tank Y1 and essential oil The liquid storage tank Y2 is connected through the pipeline 10, the front part of the pipeline 10 is provided with a branch pipeline 11, and the other end of the branch pipeline 11 is connected to the rear part of the pipeline 10;

[0118] The temperature measurement and control-ultrasonic aging unit is arranged on the branch pipeline 11;

[0119] The temperature measurement and control-ultrasonic aging unit includes a thermostatic tube A1, a thermostat B1 and an ultrasonic aging device. The thermostatic tube A1 has an inner and outer tube structure, and the inner tube of the thermostatic tube A1 is embedded in the branch pipeline 11. An acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com