Oxygen supply system, oxygen supply method and control method of oxygen-enriched blast furnace

An oxygen supply system and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of oxygen supply system pressure, flow instability, low oxygen enrichment rate, and limited oxygen enrichment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

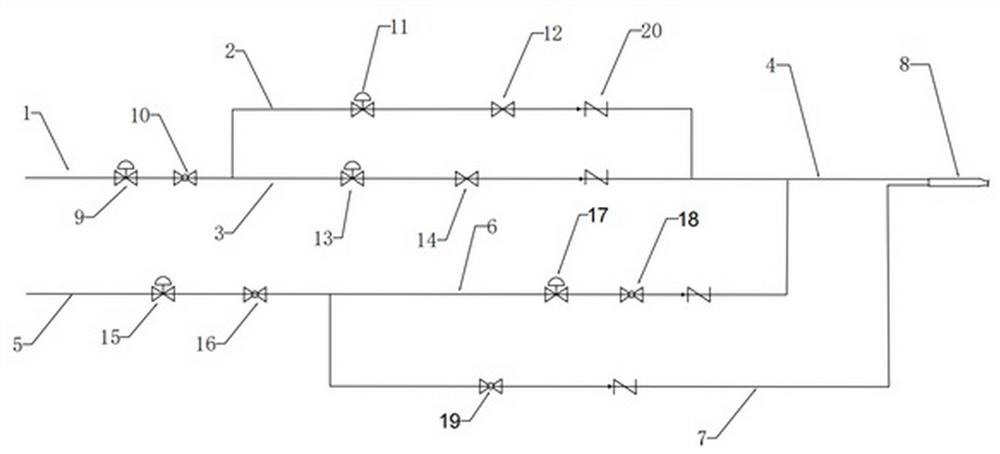

[0026] See Figure 1 , the present embodiment provides an oxygen-enriched blast furnace oxygen supply system, comprising a primary pressure control valve table, a secondary double-wire control valve platform, a security emergency control system and a mixed injection air outlet device, a primary pressure stabilization control valve table and a secondary double-wire control valve table in series, a primary pressure control valve table comprising a front oxygen main tube, the front oxygen main pipe is provided with an oxygen pressure regulating valve PCV121 and an oxygen globe valve FT121, and a secondary double-wire control valve includes a first oxygen branch and a second oxygen branch, The first oxygen branch and the second oxygen branch are connected in parallel, the first oxygen branch is provided with oxygen flow control valve FCV122 and oxygen fast cutting valve ZY122, the second oxygen branch is provided with oxygen flow control valve FCV123 and oxygen fast cutting valve ZY1...

Embodiment 2

[0030] The present embodiment provides an oxygen enrichment blast furnace oxygen supply method, comprising the following steps:

[0031] (1) Set the nitrogen pressure target value, open the nitrogen cut-off valve PT141, the nitrogen pressure regulating valve PCV201 is in the automatic state, and start automatically tracking the set pressure target value, set the oxygen pressure target value, open the oxygen globe valve FT121, the oxygen pressure regulating valve PCV121 in the automatic state and start the automatic tracking to set the pressure target value;

[0032] (2) Open the nitrogen globe valve ZY141, nitrogen flow control valve FCV141 preset opening of 20%;

[0033] (3) After 30 seconds, open the oxygen fast cutting valve ZY122, the oxygen flow control valve FCV122 starts the action, and after the opening degree of 5%, it begins to track the set oxygen enrichment rate flow, and gradually introduces oxygen into the blast furnace;

[0034] (4) After 5 minutes, the oxygen flow ...

Embodiment 3

[0036] The present embodiment provides an oxygen enrichment blast furnace oxygen supply method, comprising the following steps:

[0037] (1) Set the nitrogen pressure target value, open the nitrogen cut-off valve PT141, the nitrogen pressure regulating valve PCV201 is in the automatic state, and start automatically tracking the set pressure target value, set the oxygen pressure target value, open the oxygen globe valve FT121, the oxygen pressure regulating valve PCV121 in the automatic state and start the automatic tracking to set the pressure target value;

[0038] (2) Open the nitrogen globe valve ZY141, nitrogen flow control valve FCV141 preset opening of 20%;

[0039] (3) After 60 seconds, open the oxygen fast cutting valve ZY123, the oxygen flow control valve FCV123 action, the starting degree of 5% after the start to track the set oxygen enrichment rate flow;

[0040] (4) After 4 minutes, the oxygen flow reaches the set value of 70%, the nitrogen flow control valve FCV141 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com