Production line for producing brick making material by mixing building raw materials with sludge

A production line and sludge technology, which is applied in the field of sludge treatment and resource utilization, can solve the problems of large consumption and high cost, and achieve the effect of effective mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

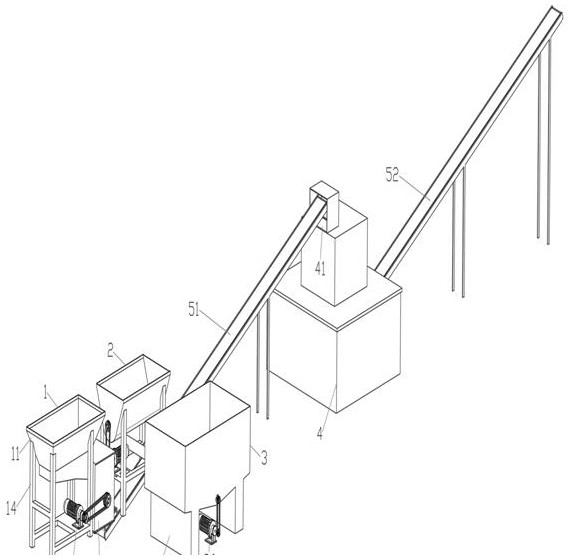

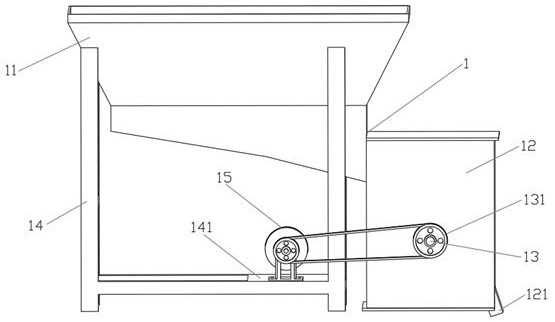

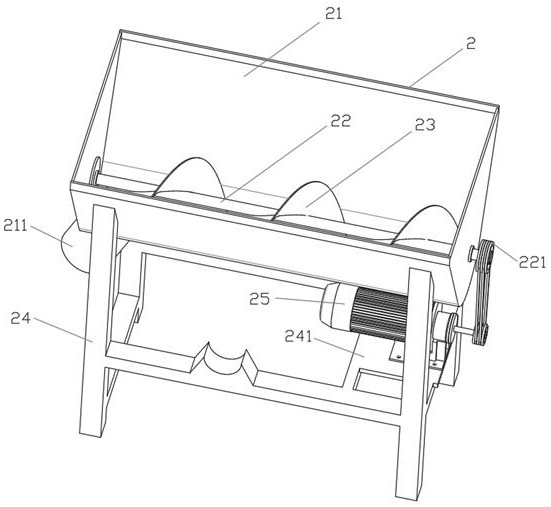

[0042] Such as Figure 1-10 As shown, the production line for producing brick-making materials by mixing sludge with building materials raw materials in this embodiment includes a crushing mechanism 1, a sludge crushing mechanism 2, a sludge transfer mechanism 3, a mixing and crushing mechanism 4, a conveying mechanism 5 and a control system:

[0043] The crushing mechanism 1 includes a first material box 11 and a pulverizer 12 with an open upper end, the first material box 11 is provided with a discharge port at the lower end of the side surface near the pulverizer 12, and the pulverizer 12 is close to the first material box 11- The upper end of the side surface is provided with a material inlet, and the discharge port is sealed and connected with the material inlet. A main shaft 13 extends from the middle and lower parts of the surface on both sides of the material inlet of the pulverizer 12, and the two ends of the main shaft 13 are provided with a main shaft pulley 131. 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com