Application of polyvinyl alcohol material, material for straw, preparation method of material and straw

A technology of polyvinyl alcohol and polyethylene glycol, which is applied in the field of straw materials, can solve the problems of straw materials that are difficult to decompose, environment, and soil pollution, and achieve the effects of short production cycle, high transparency, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

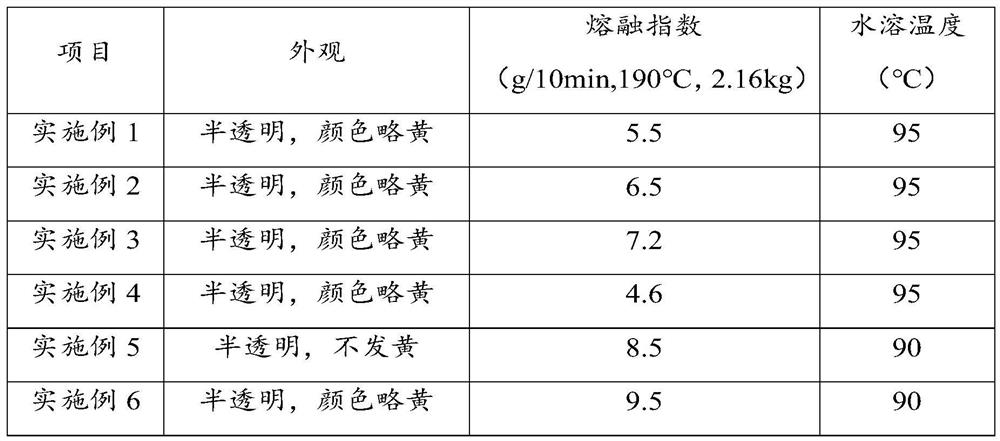

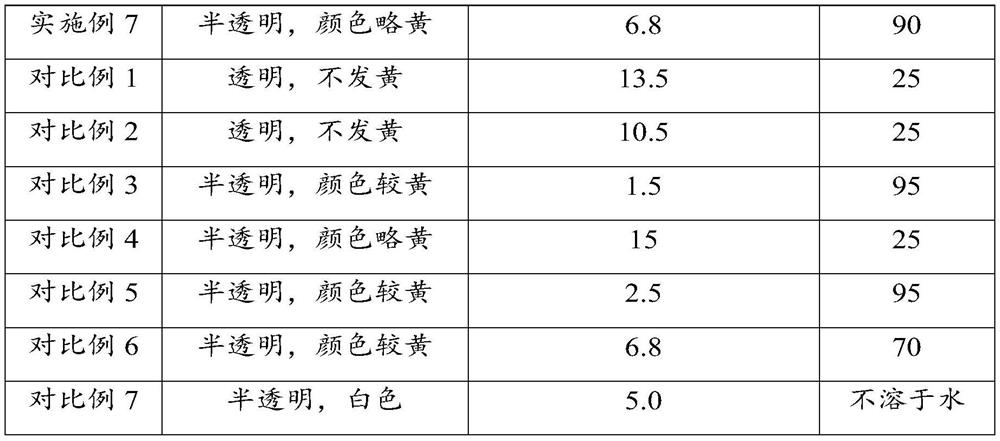

Examples

preparation example Construction

[0098] In a third aspect, in at least one embodiment, a method for preparing a straw material is provided, comprising the following steps:

[0099] The polyvinyl alcohol, the plasticizer and the processing aid are uniformly mixed at first, and then extruded and granulated to obtain the straw material.

[0100] The preparation method of the material for straws of the present invention is simple in operation and easy to implement. After fully mixing the raw materials uniformly, the materials or products for straws can be obtained through one-time melt extrusion, granulation or direct molding, which has strong controllability and is easy to produce. The cycle is short, and it is easy to realize industrialization.

[0101] In a preferred embodiment, polyvinyl alcohol is first added to the high-speed mixer, then the plasticizer and processing aid are added to the high-speed mixer, stirred, and discharged; then transferred to the twin-screw extruder, performing extrusion granulatio...

Embodiment 1

[0113] A material for straws, mainly prepared from the following raw materials in parts by weight:

[0114] Polyvinyl alcohol II (polymerization degree 3500, alcoholysis degree 99%, average particle size 100 μm) 60 parts, polyvinyl alcohol Ⅰ (polymerization degree 500, alcoholysis degree 99%, average particle size 100 μm) 40 parts, sorbitol 8 parts , 1 part of glycerol and 1 part of polyethylene glycol (polyethylene glycol 400) with a molecular weight of 400.

[0115] The preparation method of above-mentioned straw material, comprises the following steps:

[0116] Weigh 60kg polyvinyl alcohol II (polymerization degree 3500, alcoholysis degree 99%, average particle diameter 100μm) and 40kg polyvinyl alcohol I (polymerization degree 500, alcoholysis degree 99%, average particle diameter 100μm) and add to the high-speed mixer Mix at medium and high speed for 2 minutes, then slowly add 8kg of sorbitol, 14kg of glycerol, and 1kg of polyethylene glycol 400. After all are added, con...

Embodiment 2

[0119] A material for straws, mainly prepared from the following raw materials in parts by weight:

[0120] Polyvinyl alcohol II (polymerization degree 2000, alcoholysis degree 99%, average particle size 500 μm) 70 parts, polyvinyl alcohol Ⅰ (polymerization degree 800, alcoholysis degree 95%, average particle size 500 μm) 30 parts, sorbitol 4 parts , 11 parts of glycerol, 7 parts of propylene glycol and 3 parts of polyethylene glycol (polyethylene glycol 1000) with a molecular weight of 1000.

[0121] The preparation method of above-mentioned straw material, comprises the following steps:

[0122] Weigh 70kg polyvinyl alcohol II (polymerization degree 2000, alcoholysis degree 99%, average particle diameter 500μm) and 30kg polyvinyl alcohol Ⅰ (polymerization degree 800, alcoholysis degree 95%, average particle diameter 500μm) and add them into the high-speed mixer Mix at medium and high speed for 2 minutes, then slowly add 11kg of glycerin, 7kg of propylene glycol, 4kg of sorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com