Efficient vanadium-nitrogen alloy production device

A vanadium-nitrogen alloy and production device technology, which is applied in the field of vanadium-nitrogen alloy production facilities, can solve problems such as less adjustment range, high maintenance costs, and large fluctuations, and achieve faster mass and heat transfer rates, long service life of equipment, and The effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

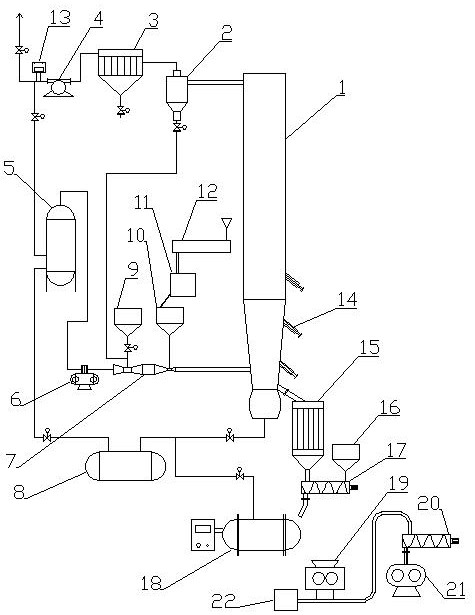

[0040] Combine below figure 1 , the present invention is illustrated by examples: a high-efficiency vanadium-nitrogen alloy production device mainly includes a boiling nitriding furnace 1, a cyclone separator 2, a dust collector 3, an exhaust fan 4, a nitrogen mixing tank 5, a booster fan 6, an atomizing Device 7, nitrogen tank 8, cooler 15, dry mixer 17, sintering furnace 18, mill 19, wet mixer 20, ball press 21.

[0041] The boiling nitriding furnace 1, the cyclone separator 2, the dust collector 3, the exhaust fan 4, the nitrogen mixing tank 5, the booster fan 6, and the atomizer 7 are connected in sequence through pipelines to form a gas recycling loop.

[0042] The atomizer 7 is divided into two-stage atomizers, the first-stage atomizer is connected to the carbon powder metering tank 9 through a pipeline, and the pipeline is provided with a metering regulating valve; the second-stage atomizer and the V 2 o 5 The molten liquid storage barrel 10 is connected with a pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com