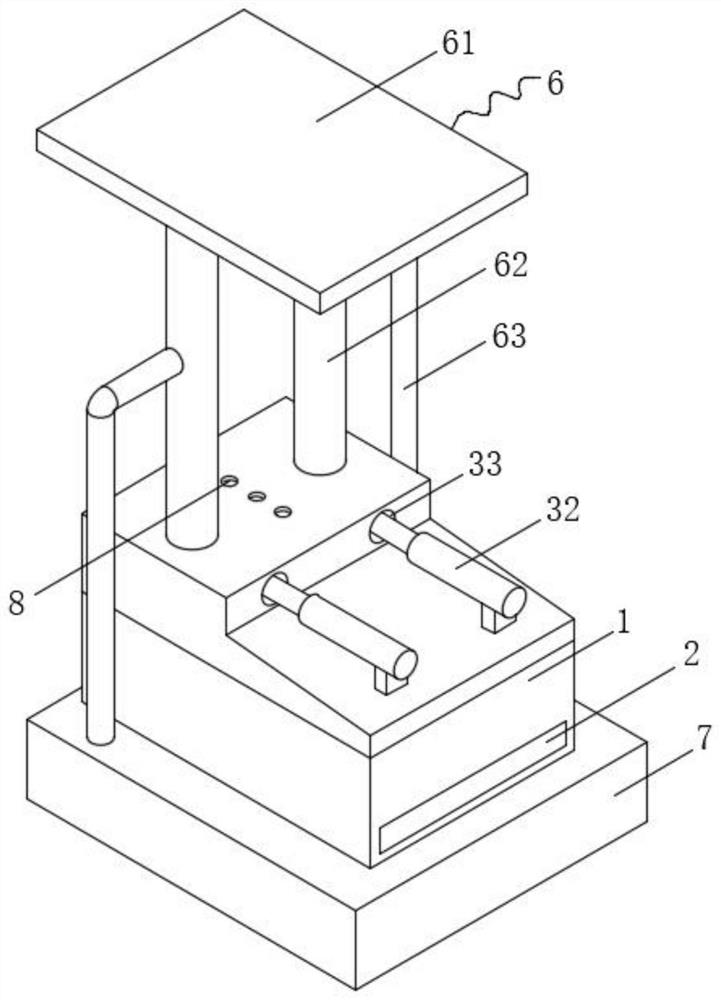

High-safety chemical raw material processing device for continuous production

A technology of chemical raw materials and processing equipment, which is applied in the field of chemical raw material processing equipment for continuous production, can solve the problems of increasing the power of electric heating equipment, inability to effectively save energy, and dissipation of hot air, so as to save energy, avoid the loss of a large amount of hot air, Good heating and heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

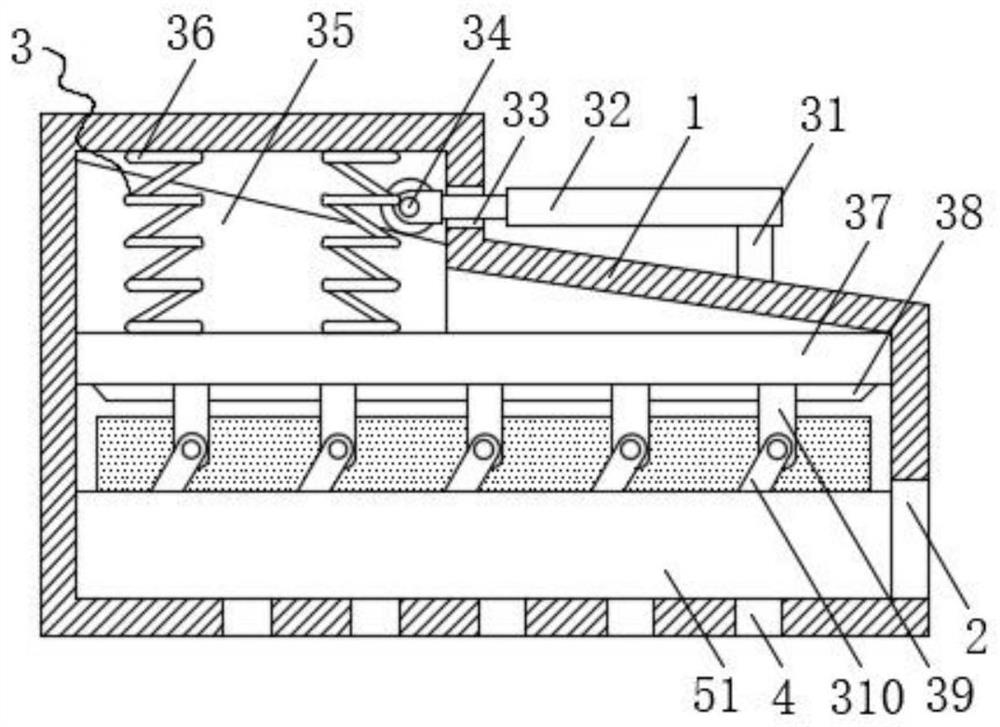

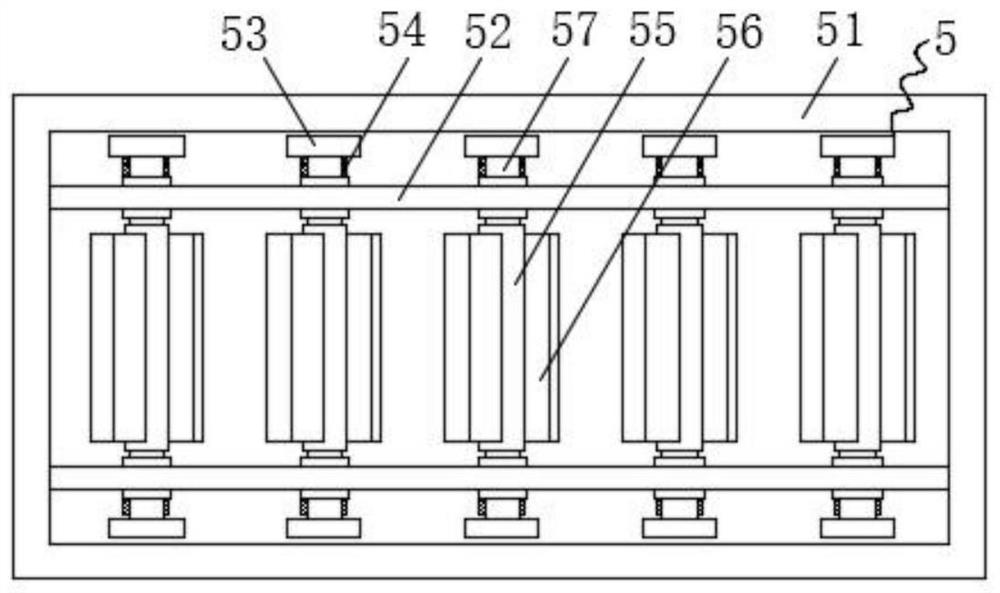

specific Embodiment approach

[0034] The specific implementation method is: by setting the material holding mechanism 5, when the piston plate 37 moves downward, it drives the fixed rod 39 to move downward. The rotating shaft 57 drives the roller 55 to rotate, and the rotation of the roller 55 can drive a plurality of turning plates 56 to rotate. The turning of the turning plates 56 can effectively stir the raw materials to achieve the effect of turning over the raw materials. The raw material is dried evenly and better. By setting the first spring 36, when the roller 34 moves and no longer squeezes the triangular block, the first spring 36 can shrink and drive the piston plate 37 to move up, and the piston plate 37 moves up to drive the rack 311 returns to the initial position. When the piston plate 37 moves up and down repeatedly, a plurality of material turning plates 56 can be turned forward and backward repeatedly to achieve a better material turning effect. By setting the first heat conducting wire 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com