Manufacturing method of component electrode

A manufacturing method and technology of components, applied in electrical components, inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve problems such as defects, poor electrode quality, electrode afterimage, etc., and achieve high Quality effect, high product sense, and the effect of solving afterimages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

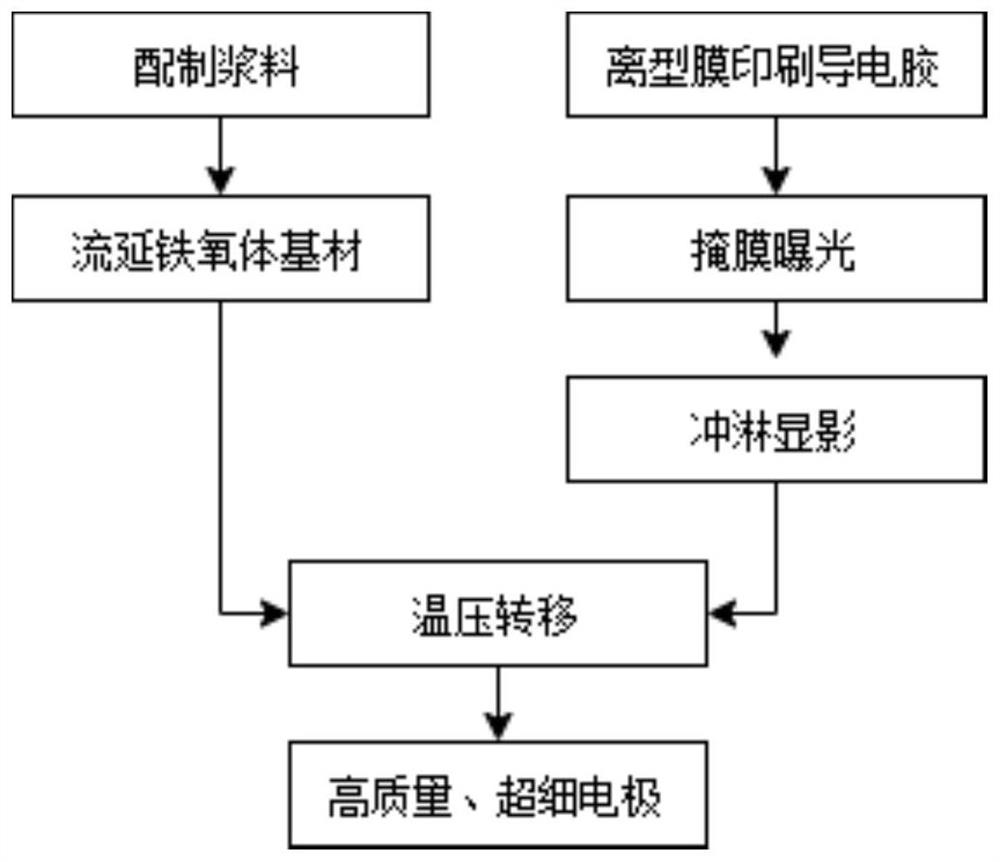

[0038] An embodiment of the manufacturing method of the component electrode of the present invention, combining figure 1 , including the following steps:

[0039] (1) Preparation of slurry: According to the percentage of the total weight of raw materials, 50-60% of ferrite powder, 5-8% of PVB resin, 2-5% of plasticizer, 0.5-1% of dispersant and 10-10% of solvent 15% mixed evenly to prepare ferrite slurry;

[0040] (2) Cast ferrite substrate: apply and cast the ferrite slurry, and dry to form a ferrite substrate with a thickness of 30 μm;

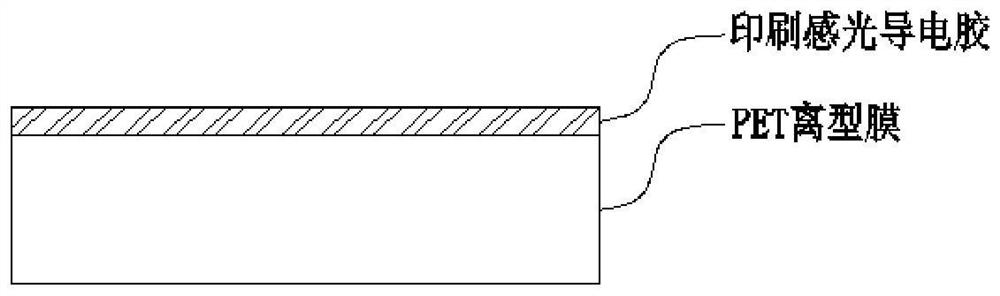

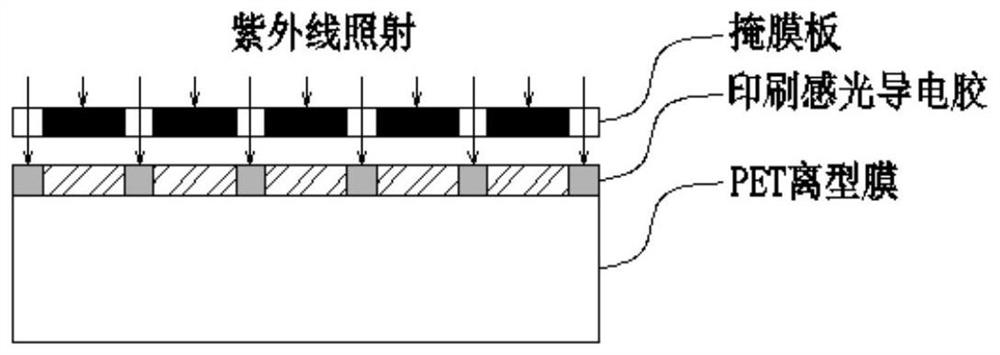

[0041] (3) Release film printing conductive adhesive: photosensitive conductive adhesive by weight percentage, including: conductive powder (silver powder) 80%, glass component (Na 2 SiO 3 , CaSiO 3 , SiO 2 、Na 2 O CaO 6SiO 2 At least one of silicate double salt) 2%, photosensitive resin composition (at least one of polyvinyl cinnamate, PVB resin, ethyl cellulose) 18%. Such as figure 2 As shown, on the PET release film, print a pho...

Embodiment 2

[0047] An embodiment of the manufacturing method of the component electrode of the present invention, combining figure 1 , including the following steps:

[0048] (1) Preparation of slurry: According to the percentage of the total weight of raw materials, 50-60% of ferrite powder, 5-8% of PVB resin, 2-5% of plasticizer, 0.5-1% of dispersant and 10-10% of solvent 15% mixed evenly to prepare ferrite slurry;

[0049] (2) Cast ferrite substrate: apply and cast the ferrite slurry, and dry to form a ferrite substrate with a thickness of 10 μm;

[0050] (3) Release film printing conductive adhesive: photosensitive conductive adhesive by weight percentage, including: conductive powder (silver powder) 80%, glass component (Na 2 SiO 3 , CaSiO 3 , SiO 2 、Na 2 O CaO 6SiO 2 At least one of silicate double salt) 2%, photosensitive resin composition (at least one of polyvinyl cinnamate, PVB resin, ethyl cellulose) 18%. Such as figure 2 As shown, on the PET release film, print a photo...

Embodiment 3

[0055] An embodiment of the manufacturing method of the component electrode of the present invention, combining figure 1 , including the following steps:

[0056] (1) Preparation of slurry: According to the percentage of the total weight of raw materials, 50-60% of ferrite powder, 5-8% of PVB resin, 2-5% of plasticizer, 0.5-1% of dispersant and 10-10% of solvent 15% mixed evenly to prepare ferrite slurry;

[0057] (2) Cast ferrite substrate: apply and cast the ferrite slurry, and dry to form a ferrite substrate with a thickness of 50 μm;

[0058] (3) Release film printing conductive adhesive: photosensitive conductive adhesive by weight percentage, including: conductive powder (silver powder) 80%, glass component (Na 2 SiO 3 , CaSiO 3 , SiO 2 or Na 2 O CaO 6SiO 2 At least one of silicate double salt) component 2%, photosensitive resin composition (at least one of polyvinyl alcohol cinnamate, PVB resin, ethyl cellulose) 18%. Such as figure 2 As shown, on the PET relea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com