Ceramic-based diamond grinding wheel for grinding semiconductor plastic package body and manufacturing method of ceramic-based diamond grinding wheel

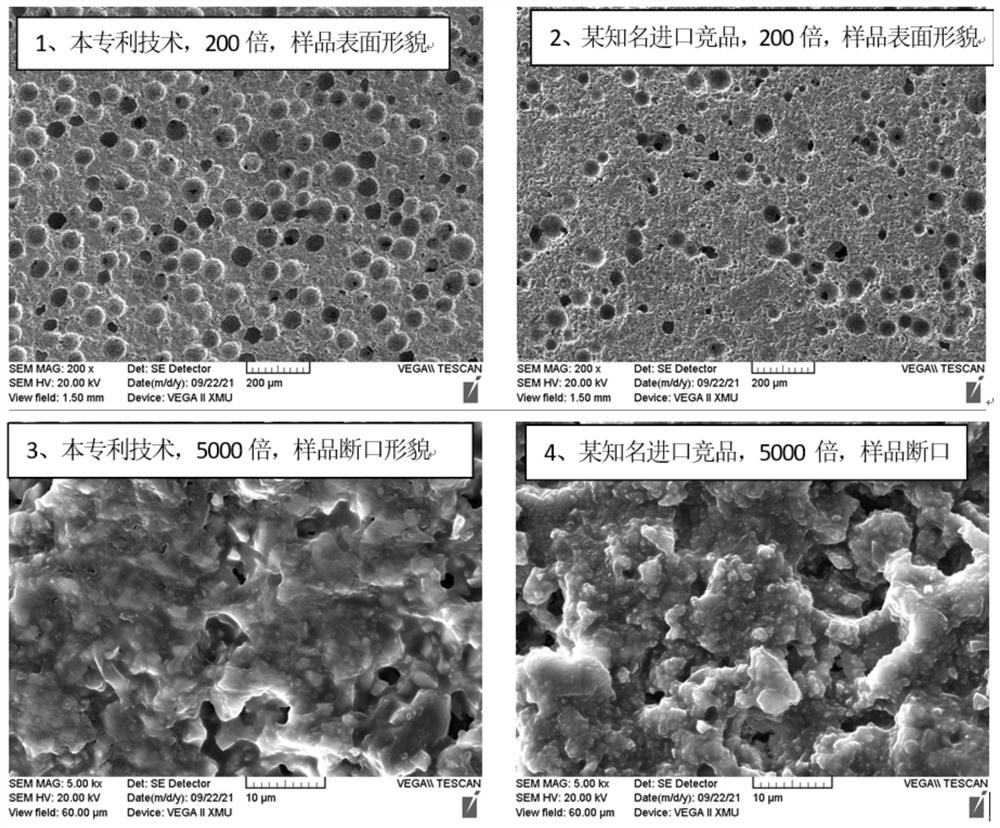

A manufacturing method and technology of plastic packaging, applied in the direction of ceramic products, manufacturing tools, abrasives, etc., can solve the problems of low service life of grinding wheels, low surface finish of products, etc., and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

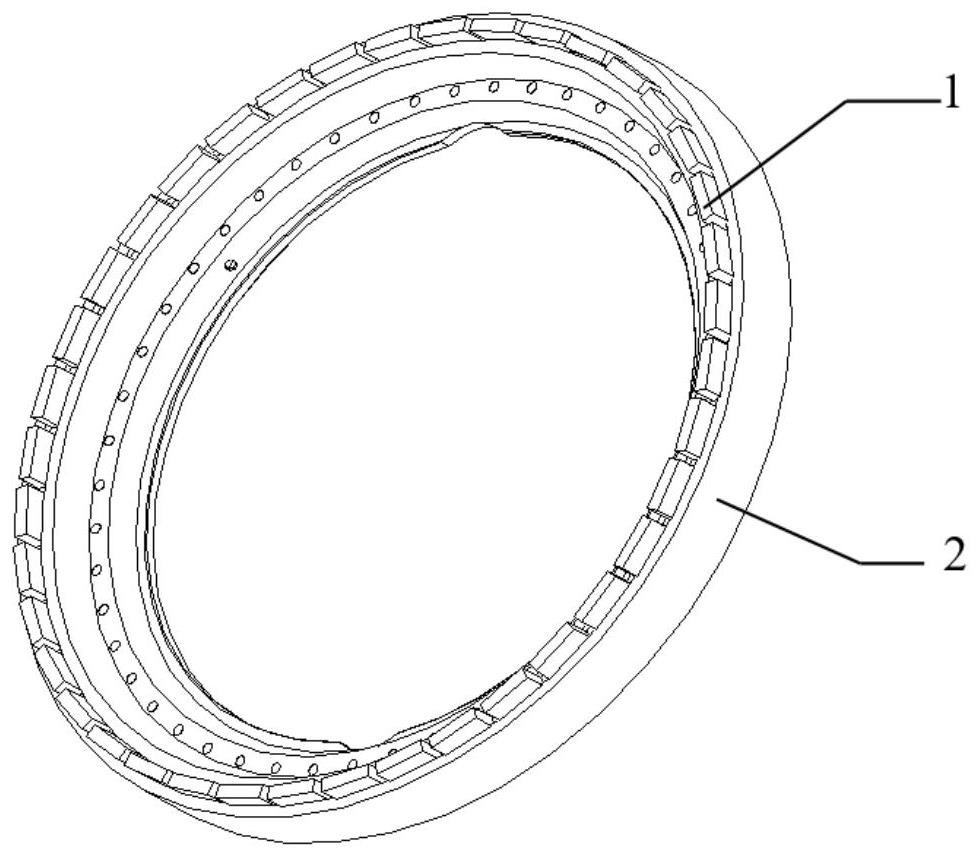

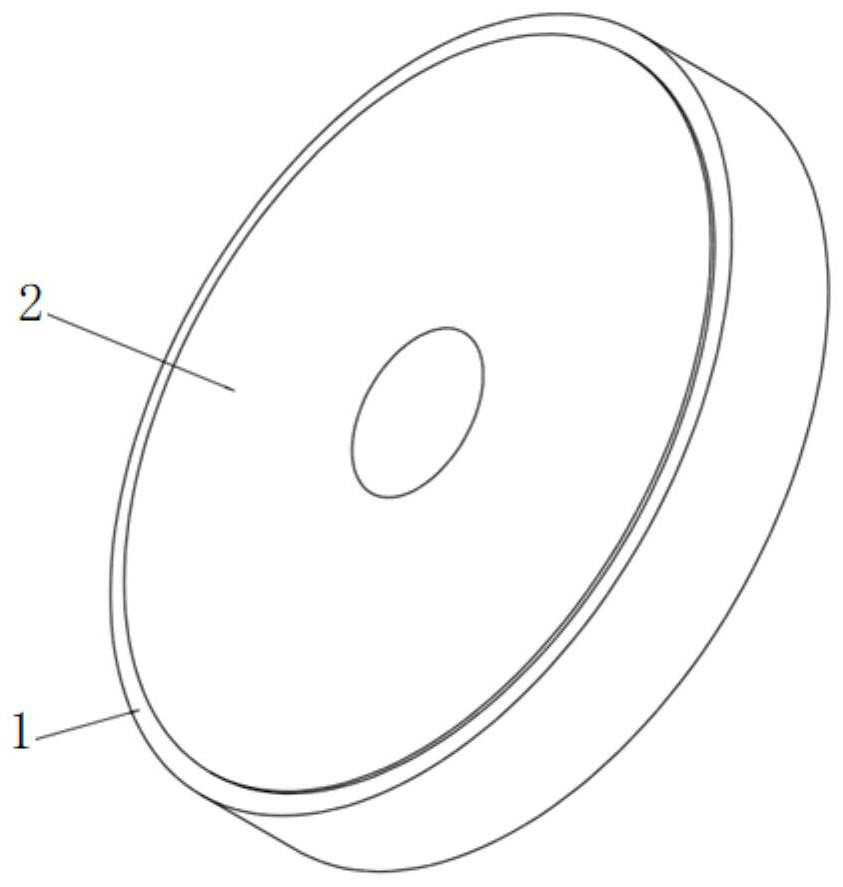

[0048] The vitrified diamond grinding wheel for grinding semiconductor plastic package of the present invention is composed of an aluminum alloy substrate and a grinding block bonded on the aluminum alloy substrate;

[0049] The grinding block is composed of 35-50% vitrified bond, 35-50% diamond powder, 10-20% pore-forming agent and 5-10% auxiliary agent in mass percentage, after mixing, compression molding, heat treatment and Obtained after sintering treatment; wherein, the vitrified bond has a particle size of 10-50 μm, and the vitrified bond includes 50-70% silicon dioxide, 5-15% diboron trioxide, 5-15% aluminum oxide, 5-10 % Calcium Oxide, 1-5% Sodium Oxide and 1-5% Magnesium Oxide. The diamond powder is sieved polycrystalline diamond powder with a particle size of 5-50 μm. The type of pore-forming agent is silica ball or acrylic, the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com