Gasification furnace system and operation process thereof

A technology of gasification furnace and process, which is applied in the field of coal gasification, and can solve problems such as damage, equipment pipeline blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

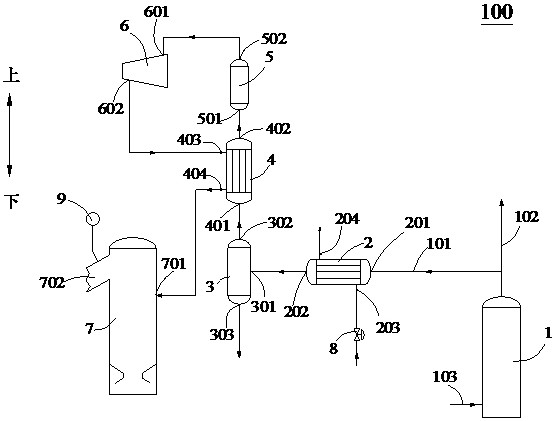

[0037] Embodiments of the present invention are described in detail below, examples of the embodiments are shown in the accompanying drawings. The embodiments described below by reference to the accompanying drawings are exemplary and are intended to be used to explain the present invention, and cannot be construed as a limitation of the present invention.

[0038] as Figure 1 As shown, according to an embodiment of the present invention, the gasifier system 100 includes a scrubber 1, a gasifier 7, a cooler 2, an ammonium separation tank 3 and a compressor 6.

[0039]The gasifier 7 has a syngas outlet 702 and an excitation air inlet 701. Scrubber tower 1 having a syngas inlet 103, a first excitation air outlet 101 and a second excitation air outlet 102, a syngas inlet 103 of the scrubber tower 1 is connected to the syngas outlet 702 of the gasifier 7. Cooler 2 having a coolant inlet 203, a coolant outlet 204, an excitation air cooling inlet 201 and an excitation air cooling outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com