Wooden biomass combined heat and power generation facility for continuously generating heat and electricity

A woody biomass and cogeneration technology, applied in lighting and heating equipment, preheating, mechanical equipment, etc., can solve the problems of lack of electricity warning warning function, debris and dust polluting the environment, and easy to affect the crushing effect, etc. Achieve the effect of avoiding heat loss, avoiding environmental pollution, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

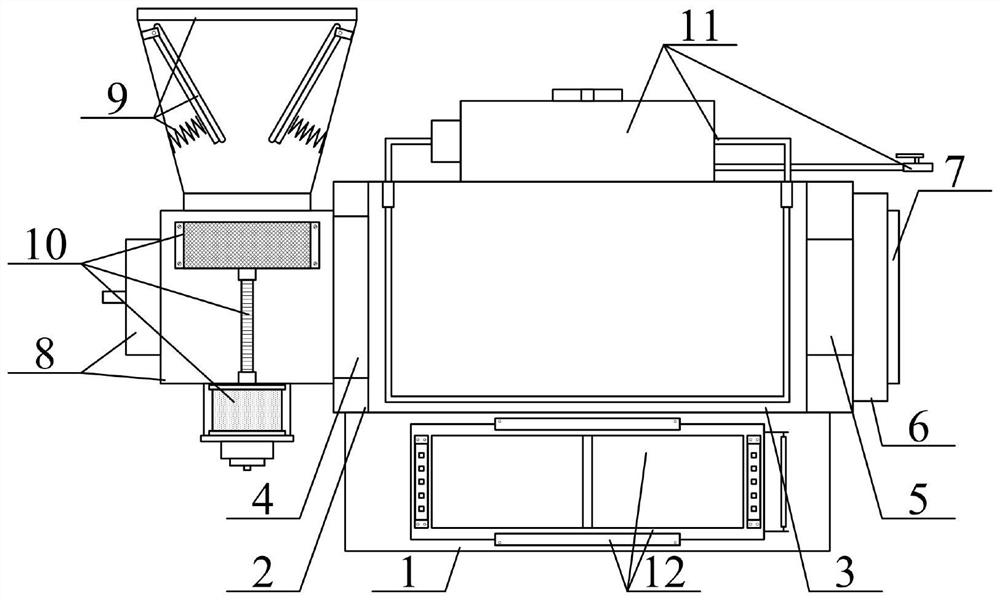

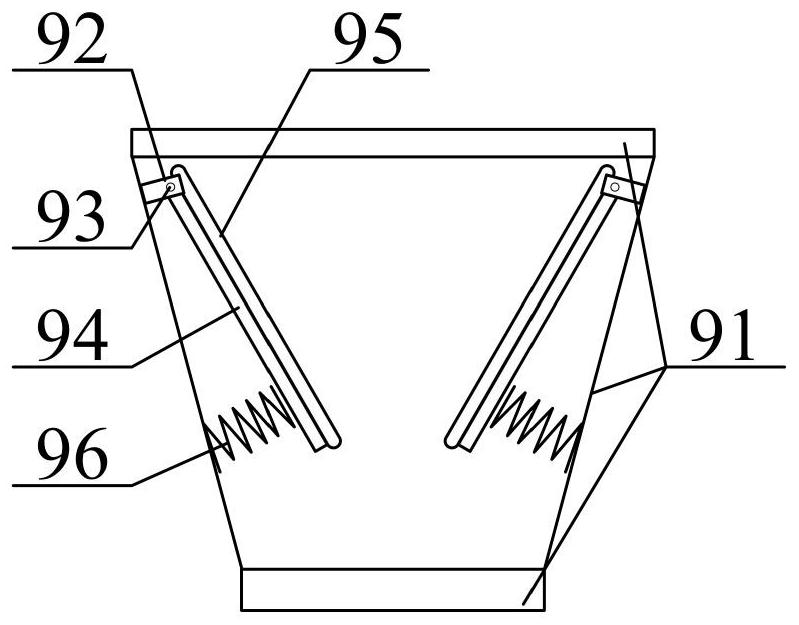

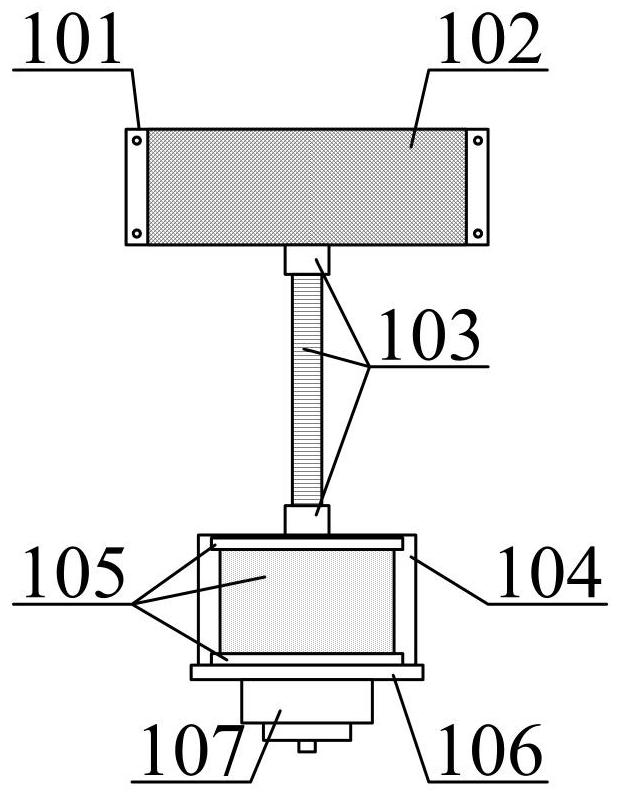

[0032] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a woody biomass cogeneration facility for continuously generating heat and electricity includes a facility base 1, a cogeneration device 2, a cogeneration combustion chamber 3, a connecting conduit 4, a generator 5, and a transformer 6. Power supply terminal 7 and woody bio-shredder 8, the cogeneration equipment 2 is connected to the upper part of the facility base 1 by bolts; the cogeneration equipment 2 is provided with a combustion chamber 3 for cogeneration of heat and electricity; The left side inlet of the heat and power cogeneration combustion chamber 3 is threadedly connected with a connecting conduit 4; the woody biological pulverizer 8 is bolted to the left side inlet of the cogeneration equipment 2, and is communicated with the connecting conduit 4; The generator 5 described above is bolted to the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com