Polishing roller air drying equipment

A polishing roller and equipment technology, applied in the field of polishing roller air-drying equipment, can solve the problems of large occupied space, high energy consumption cost, influence on the performance of non-woven polishing roller, etc., and achieve the effect of fast drying and meeting the requirements of production cycle

Pending Publication Date: 2022-04-26

ANHUI TONGGUAN COPPER FOIL +2

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of ovens or similar devices, firstly, the equipment takes up a large space and is inconvenient to move; secondly, the energy consumption cost is high during use; thirdly, the long-term repeated heating and cooling will have an impact on the performance of the non-woven polishing roller

The traditional natural drying depends on climatic conditions. In rainy weather, the wet polishing roller needs to be left for a long time to dry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example example 1

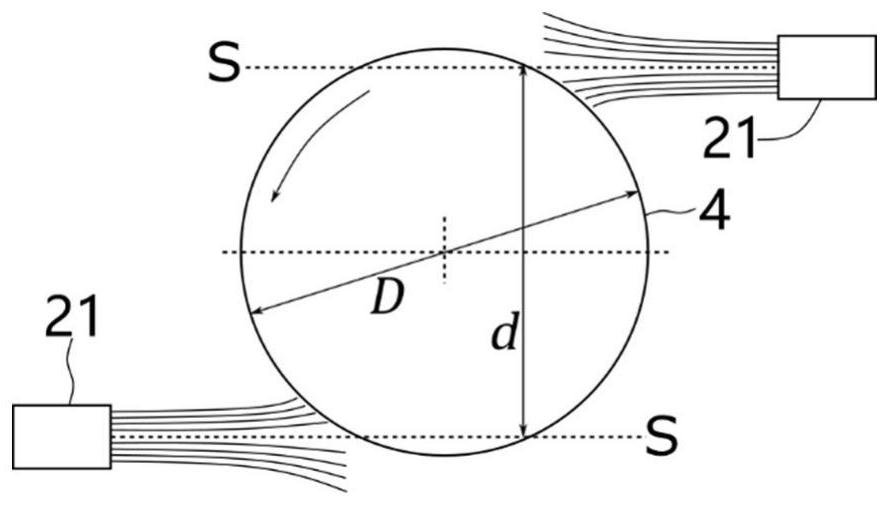

[0033] Example 1, only one air knife 21 is set, and the air knife 21 is equal to the axis O of the polishing roller 4;

Embodiment 2

[0034] Embodiment 2, only one air knife 21 is set, and the air knife 21 is at the same height as the top of the polishing roller 4;

Embodiment 3

[0035] Embodiment 3, two sets of air knives 21 are set, and the two sets of air knives 21 are of the same height as the axis O of the polishing roller 4, symmetrically placed on both sides;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

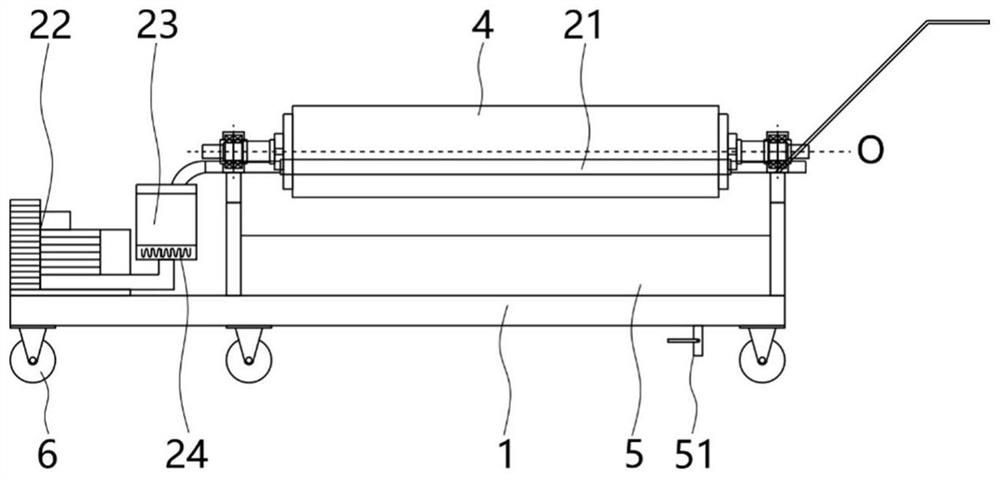

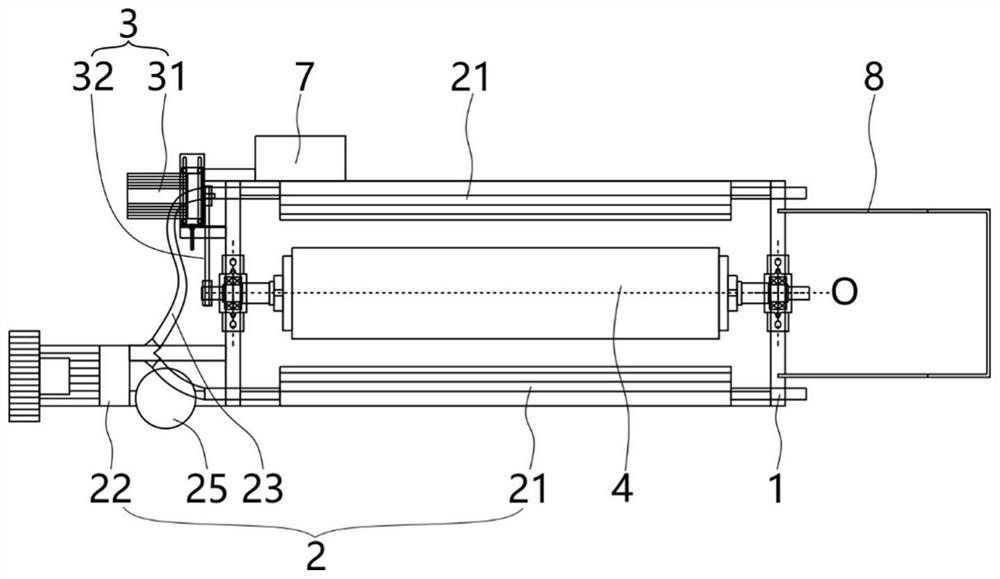

The invention provides polishing roller air-drying equipment which is used for air-drying treatment of a polishing roller and comprises an equipment body, a rotating assembly and an air supply assembly, and the rotating assembly comprises a driving device rotationally connected with the polishing roller and used for driving the polishing roller to rotate at a set speed; the air supply assembly comprises an airflow generation device and at least one set of air knives connected with the airflow generation device through a pipeline, and the air knives blow airflow pointing to the surface of the polishing roller. Air flow on the surface of the polishing roller is accelerated to flow through the air supply assembly, the polishing roller is driven to rotate through cooperation with the rotating assembly, the polishing roller can be rapidly dried under the room temperature condition, and the requirement for the production cycle of electrolytic copper foil is met.

Description

technical field [0001] The invention relates to the field of drying equipment, in particular to polishing roller air-drying equipment. Background technique [0002] With the development of lithium batteries and new energy technologies, the market demand for electrolytic copper foil is strong. In the electrolytic copper foil process, in order to ensure that the surface roughness of the copper foil meets the standard, it is necessary to use a polishing roller to polish the raw foil surface of the cathode roller in-line during the production process. [0003] The polishing roller is made of nylon fiber, bonded with abrasive materials such as corundum and silicon carbide, and is made through a non-woven process. It has a three-dimensional network structure and tiny pores, which can remove impurities and oxide films on the surface of the cathode roller during polishing. At the end of production, fine grinding is required to restore the surface quality of the polished surface. Si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F26B11/18F26B21/00F26B21/10F26B25/00F26B25/02F26B25/18

CPCF26B11/18F26B21/001F26B21/004F26B25/00F26B21/003F26B21/10F26B25/02F26B25/185Y02P70/10

Inventor 朱勇甘国庆罗健谢振家莫渺韩永强

Owner ANHUI TONGGUAN COPPER FOIL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com